Nano-oxide and carbide dispersion-strengthened low-activation steel and preparation method and application

A nano-oxide and dispersion strengthening technology, applied in the field of metal material processing, can solve the problems of low cost, difficulty in preparing large and complex components, and high efficiency, and achieve the effects of low cost, inhibition of aggregation and growth, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

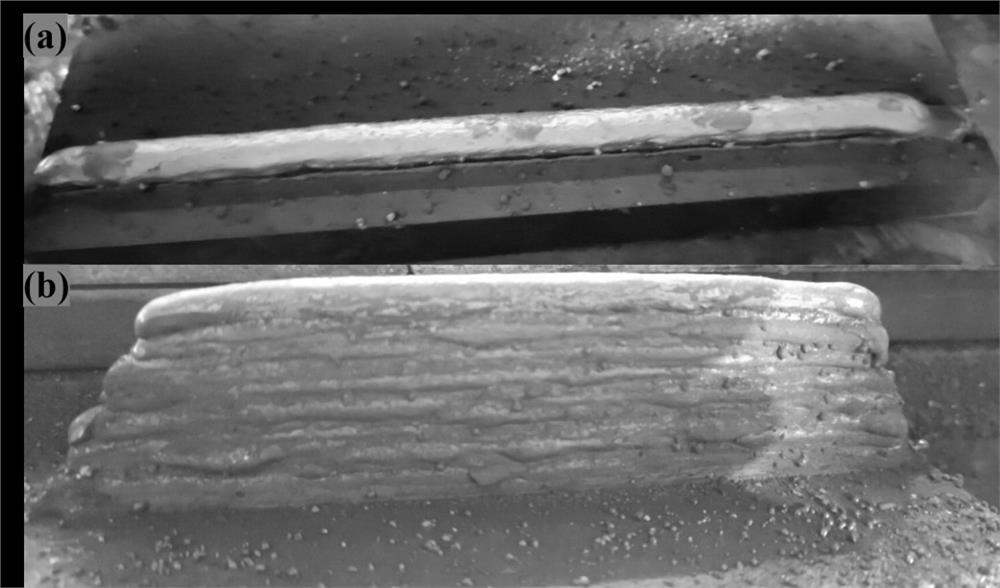

[0033] A preparation method of dispersion strengthened low activation steel, such as figure 1 shown, including the following steps:

[0034] In step 1, the alloy steel powder and nano-oxide powder are mechanically stirred by a mixer to obtain a mixed powder.

[0035]Specifically, the alloy steel powder was composed of (WFe75% 200g, Cr 900g, TiFe30% 66.7g, SiFe75% 17.8g, MnFe75% 71.1g, Fe 281.9g) and nanometer yttrium trioxide 37.5g were mixed under mechanical stirring , to obtain mixed powder. Wherein, the stirring time is 5h; the alloy steel powder is stainless steel powder or other special-purpose alloy steel powder, the average particle size is less than 100 μm, and the wire drawing formability is good; the nano-oxide powder is high melting point, high Stable Rare Earth Y 2 O 3 , and its average particle size is less than 40 nm; the mass of oxide powder in the mixed powder accounts for 0.5% of the total content.

[0036] In step 2, the mixed powder is wrapped with a st...

Embodiment 2

[0043] The main difference between this example and Example 1 is that the composition of the composite metal powder is different, and the composition and mass percentage of its main chemical components are shown in Table 2.

[0044] Table 2 embodiment 2 composite metal powder composition (wt%)

[0045] C Cr W Mn Ti Si Y 2 O 3

Embodiment 3

[0047] The main difference between this example and Example 1 is that the composition of the composite metal powder is different, and the composition and mass percentage of its main chemical components are shown in Table 3.

[0048] Table 3 embodiment 3 composite metal powder composition (wt%)

[0049] C Cr W Mn Ti Si Y 2 O 3

Fe 0.064 9.0 1.5 0.8 0.5 0.2 0.2 margin

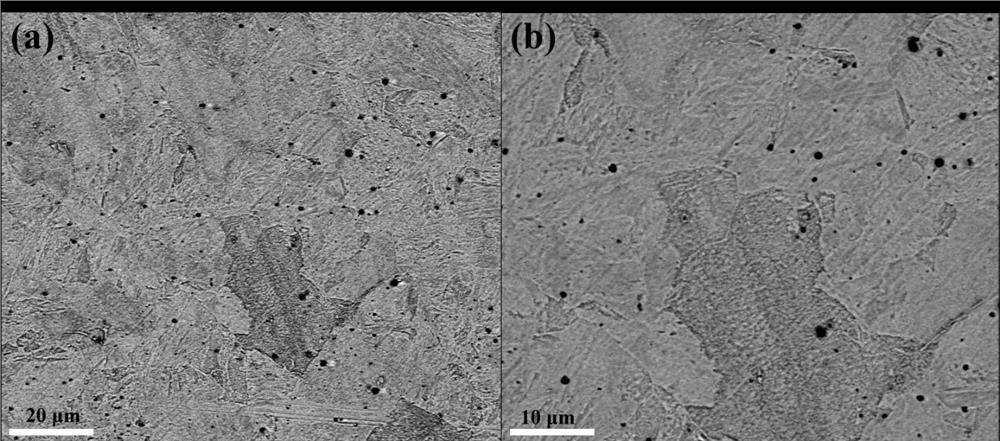

[0050] image 3 is the SEM image of the dispersion-strengthened low-activation steel material prepared in Example 1, wherein image 3 (a) is the SEM image under low magnification and image 3 (b) in the middle is the SEM image of the SEM photo under high magnification;

[0051] Depend on image 3 It can be seen that the nano-ODS and MX-strengthened low-activation steel parts prepared in Example 1 of the present application have fine oxides and MX precipitated inside the alloy structure at room temperature.

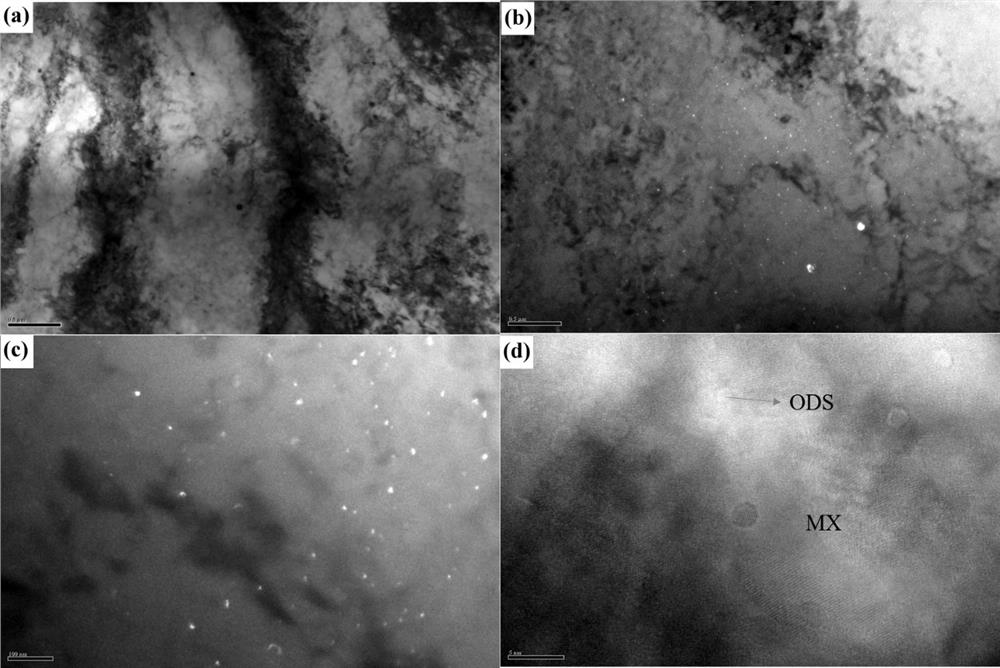

[0052] Figure 4 is the STEM image of the dispersion-stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com