Marine antifouling coating on surface of copper alloy part and preparation method thereof

A technology for marine anti-fouling and components, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the complex preparation process of cuprous oxide, difficulty in controlling the shape and structure, and poor anti-fouling effect, etc. problems, to achieve the effect of easy large-scale industrial production, good antifouling effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

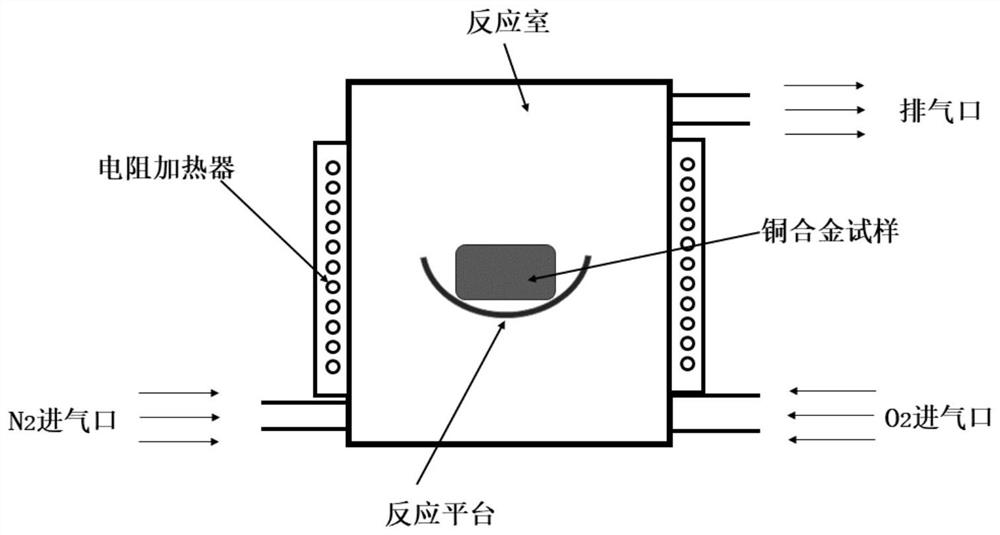

[0030] A method for preparing a marine antifouling coating on the surface of a copper alloy part provided by an embodiment of the present invention adopts such as figure 1 The shown device is carried out, specifically comprises the following steps:

[0031] Step (1): Place the copper alloy parts on the reaction platform of the reaction chamber, close the inlet and outlet of the reaction chamber, use a vacuum pump to evacuate the reaction chamber, and remove the air to make the vacuum degree reach 1×10 -4 Pa.

[0032] Step (2): After the vacuum degree meets the requirements, turn off the vacuum pump, open the inlet and outlet of the reaction chamber, and feed N into the reaction chamber. 2 gas and keep flowing N 2 , so that N 2 fill the reaction chamber;

[0033] Step (3): Heating the reaction chamber through a resistance wire, and after the temperature rises to 600°C to 1000°C, preferably 800°C to 900°C, pass O into the reaction chamber 2 and N 2 , under the nitrogen and...

Embodiment 1

[0042] Step (1): Select a copper block with a size of 10mm×10mm×2mm. The surface of the copper block is polished. After the treatment, the copper surface is cleaned with deionized water, dried and placed in a reaction chamber for use. Close the inlet and outlet of the reaction chamber, and evacuate through the vacuum pump to make the vacuum degree reach 1×10 -4 Pa.

[0043] Step (2): turn off the vacuum pump, open the inlet and outlet of the reaction chamber, and pass N at a rate of 100 sccm 2 , the time is maintained for half an hour, and the N in the reaction chamber is kept 2 ;

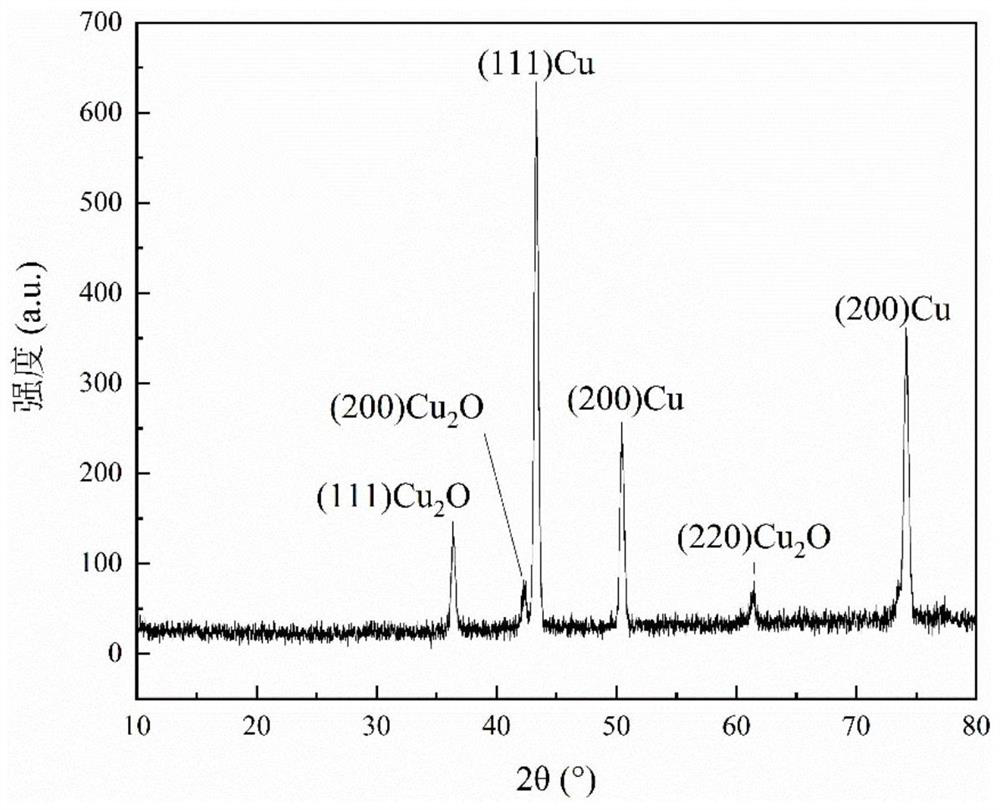

[0044] Step (3): Keep N in the reaction chamber 2 , the reaction chamber is heated by a resistance wire, and the temperature is raised at a rate of 40°C / min, so that the temperature reaches 600°C. After reaching the set temperature, feed oxygen and N 2 Two gases, O 2 The flow rate is 1 sccm, N 2 The flow rate is 100 sccm. Under nitrogen and oxygen mixed atmosphere and set temperature, keep ...

Embodiment 2

[0047] Step (1): Select a copper alloy bar with a size of 300mm×10mm×5mm. The surface of the sample is polished. After the treatment, the copper surface is cleaned with deionized water, dried and placed in the reaction chamber for later use. Close the inlet and outlet of the reaction chamber, and evacuate through the vacuum pump to make the vacuum degree reach 1×10 -4 Pa.

[0048] Step (2): turn off the vacuum pump, open the inlet and outlet of the reaction chamber, and pass N at a rate of 100 sccm 2 , the time is maintained for half an hour, and the N in the reaction chamber is kept 2 ;

[0049] Step (3): Keep N in the reaction chamber 2 , the reaction chamber is heated by a resistance wire, and the temperature is raised at a rate of 25°C / min, so that the temperature reaches 900°C. After reaching the set temperature, two gases, oxygen and N2, are introduced, O 2 The flow rate is 3sccm, N 2 The flow rate is 100 sccm. Under nitrogen and oxygen mixed atmosphere and set te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com