Fire extinguishing diaphragm capable of actively inhibiting thermal runaway of lithium battery as well as preparation method and application of fire extinguishing diaphragm

An active suppression, lithium battery technology, applied in the direction of secondary batteries, battery pack components, separators/films/diaphragms/spacers, etc., can solve the problem of poor heat resistance of the diaphragm, unstable microcapsules, and unfavorable lithium ion migration And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for actively suppressing the thermal runaway fire extinguishing diaphragm of a lithium battery, comprising the following steps:

[0041] S1, using a liquid fire extinguishing agent or a liquid coolant as a core material and an organic phase change material as a wall material to prepare a microcapsule fire extinguishing agent;

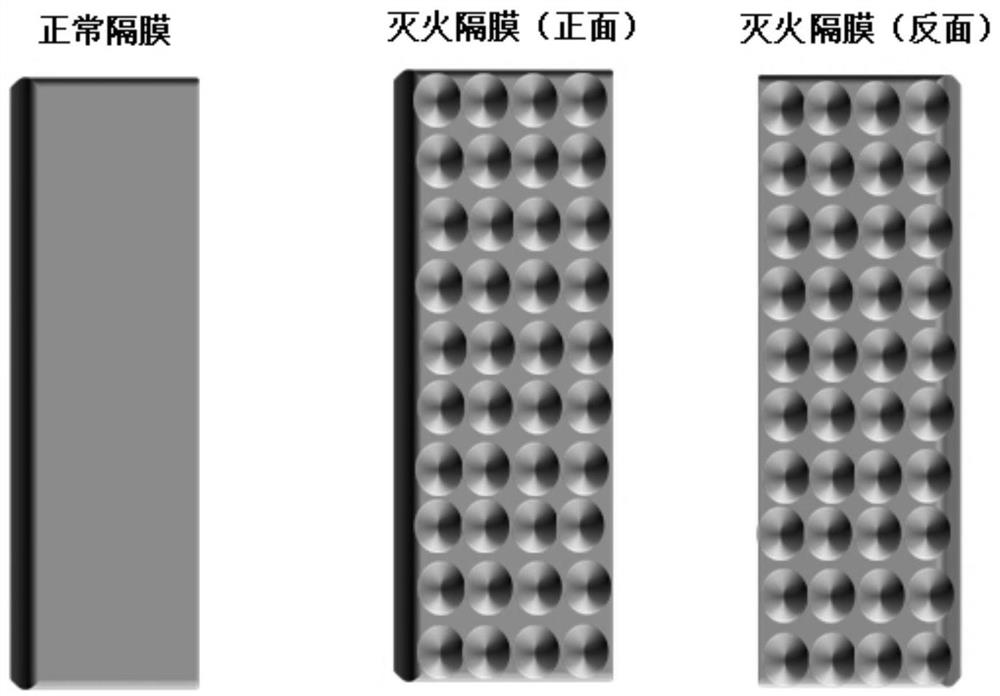

[0042] S2, adding the diaphragm matrix material into the formaldehyde solution, heating to 80-90°C and stirring, and after the diaphragm matrix material is fully dissolved, the solution casting method is used to spread the film; before the film is almost completely solidified into the diaphragm matrix, The microcapsule fire extinguishing agent is directly and evenly laid on the surface of the film that has not been fully cured and formed. After the film is completely cured and formed, the microcapsule fire extinguishing agent is evenly and tightly fixed and loaded on the surface of the diaphragm matrix, and the prep...

Embodiment 1

[0050] see figure 1 As shown, Embodiment 1 of the present invention provides a method for actively suppressing the thermal runaway fire extinguishing diaphragm of a lithium battery, comprising the following steps:

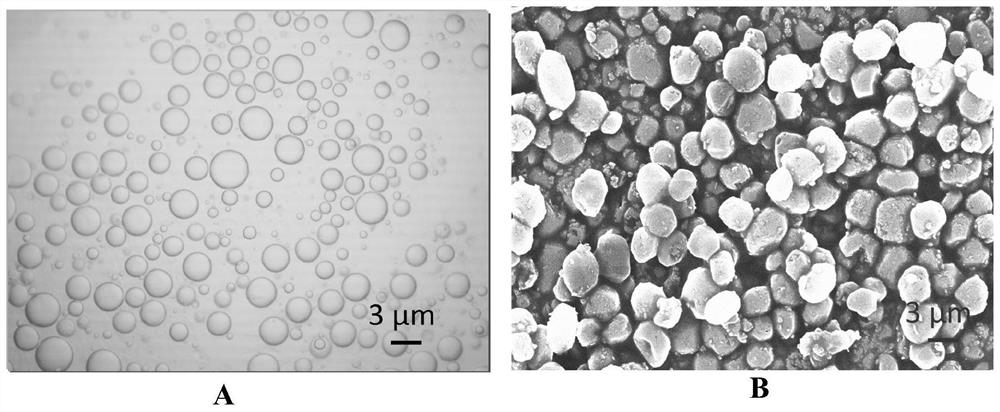

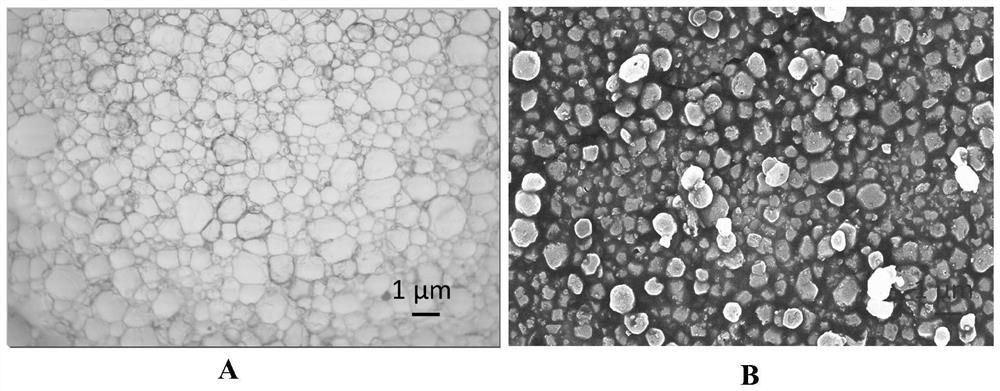

[0051] S1, using liquid fire extinguishing agent or liquid coolant as core material and organic phase change material as wall material to prepare microcapsule fire extinguishing agent, the specific process is as follows:

[0052] a. Synthesis of wall material prepolymer:

[0053] Add 5.68g of formaldehyde solution and 37.5g of deionized water into the three-necked flask, dropwise add triethylamine solution with a mass fraction of 10%, adjust the pH value to 8.5-9.0, and then add 1.2g of urea and 1.26g of melamine. Next, heat the three-neck flask in a water bath, raise it to 70°C, stir for 1 hour, then stir at a speed of 350r / min, and continue the reaction for 20 minutes after the mixed solution is clarified to obtain a MUF prepolymer with a concentration of 10wt%....

Embodiment 2-4

[0066] The difference from Example 1 lies in that: the setting of process parameters is different, as shown in the following table, and other steps are the same as in Example 1, and will not be repeated here.

[0067]

[0068] Combining the above table for analysis, the impact of the type of core material and shell material and the ratio of the two on the performance of the fire extinguishing diaphragm is: the material properties of the core material determine its fire extinguishing and cooling ability; the type of shell material determines the stability and rupture of the microcapsules The lower limit of the temperature at which the fire extinguishing agent is released; the ratio of the two affects the coating rate of the microcapsules, thereby determining the heat resistance of the diaphragm.

[0069] The impact of the diaphragm matrix material and the ratio between the diaphragm matrix and the microcapsules on the performance of the fire extinguishing diaphragm is: the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com