PET (Polyethylene Terephthalate) foam material and manufacturing method thereof

A technique for foaming materials and manufacturing methods, which is applied in the field of PET foaming materials and its manufacturing, can solve the problems that materials cannot be recycled directly, PET material degradation, material loss, etc., achieve uniform cell size, reduce degradation, and reduce heat loss. Degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

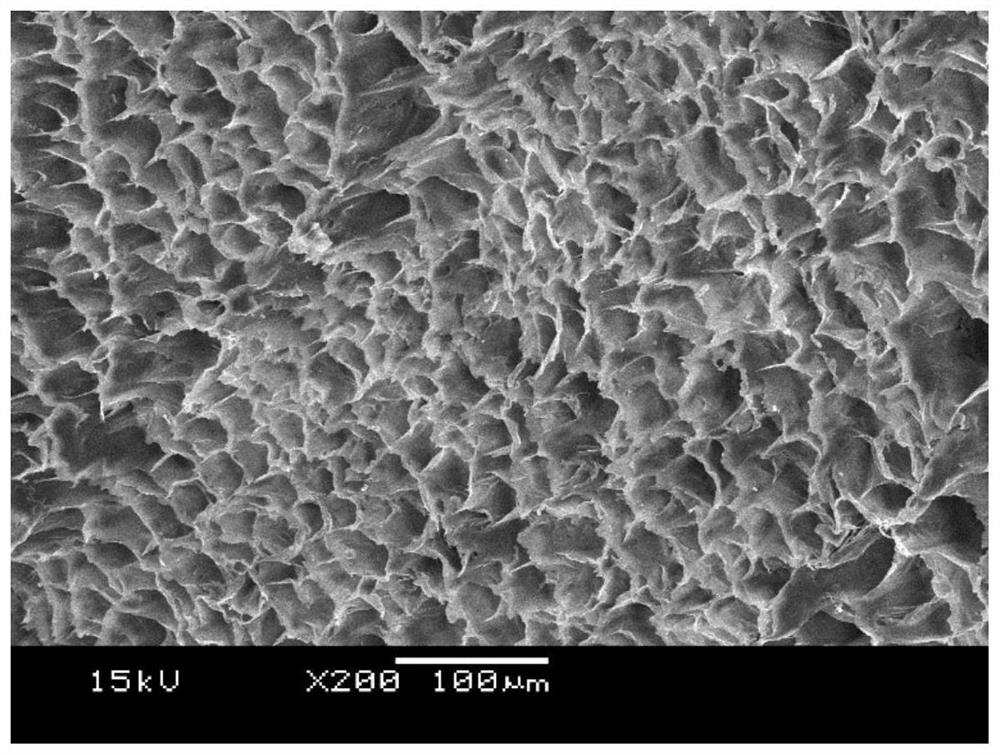

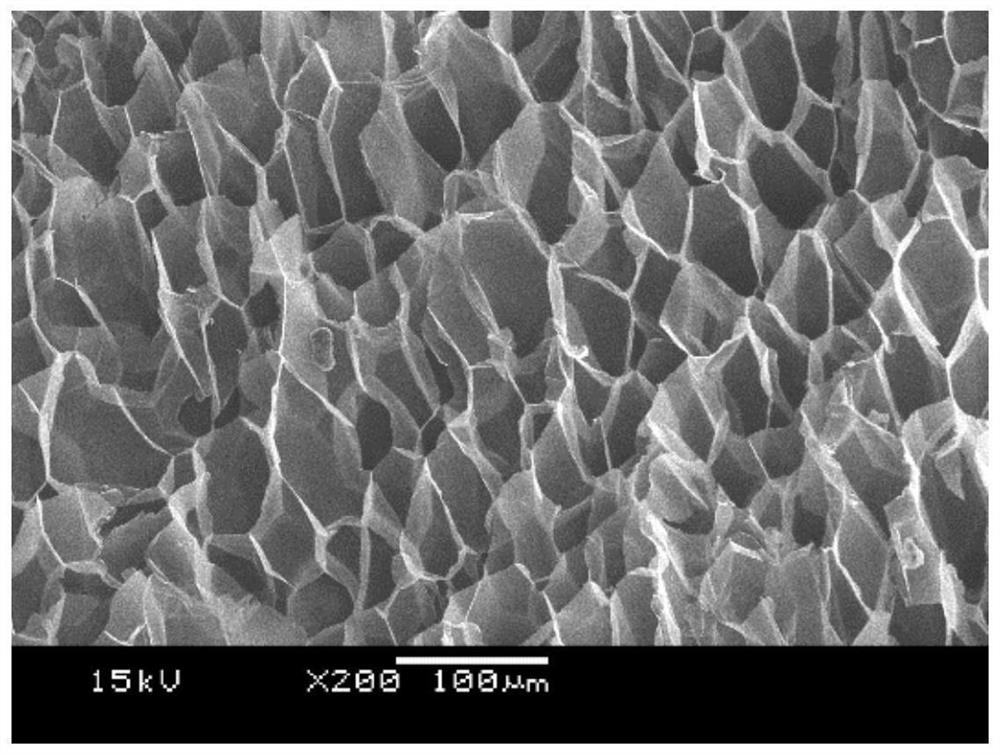

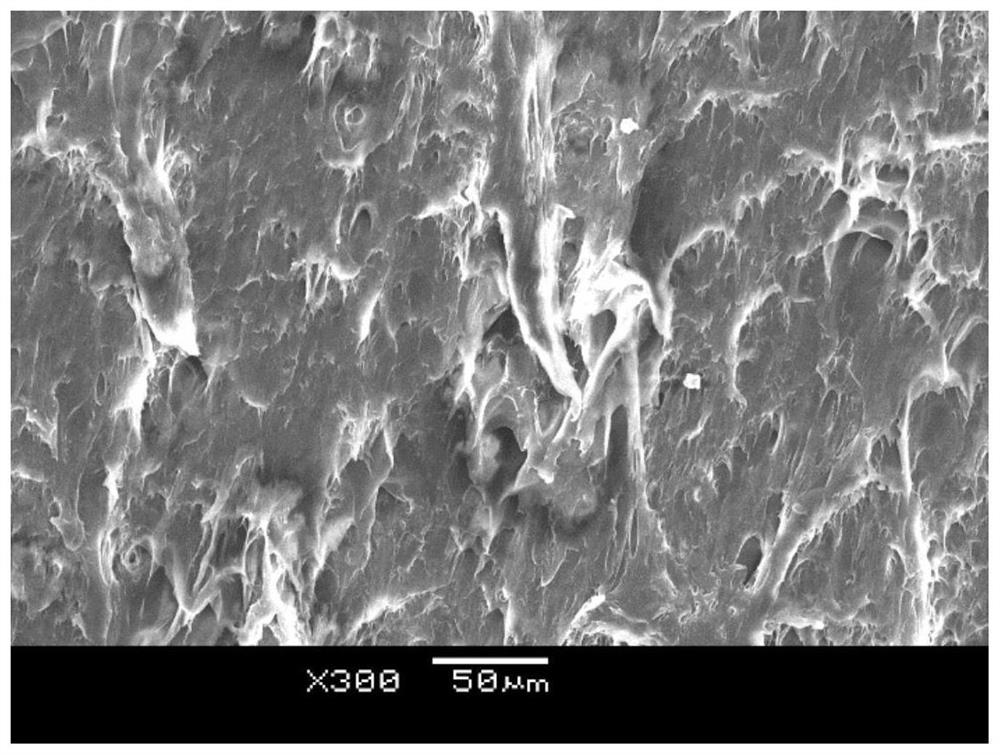

Image

Examples

preparation example 1

[0048] Repeat the embodiment 5 in the Chinese patent whose publication number is CN 108976427 A to prepare PET granules. In this preparation example, each raw material is the same as the embodiment 5. Wherein, the PET resin used is a linear PET resin (full name polyparaphenylene Ethylene glycol diformate, purchased from Shanghai Jinshan Petrochemical Co., Ltd.), the density is 1.37g / cm 3 , the melting point is 254°C, the intrinsic viscosity is 0.65Dl / g, and the melt volume flow rate is 30cm 3 / 10min, the loss factor is 20.

preparation example 2

[0050] Similar to Preparation Example 1, only the epoxy chain extender wherein The amount of 4368 acrylate polymer was replaced by 0.6 parts by weight to prepare PET particles with a loss factor of 1.

preparation example 3

[0052] Similar to Preparation Example 1, only the epoxy chain extender wherein The amount of 4368 acrylate polymer was replaced by 1.5 parts by weight to prepare PET particles with a loss factor of 0.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com