Grinding aid for improving durability of cement and preparation method of grinding aid

A technology of grinding aid and durability, which is applied in the field of grinding aid and its preparation for improving the durability of cement, can solve problems such as insufficient durability of cement, achieve good grinding aid effect, improve grinding aid effect, compressive strength and Good effect on flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

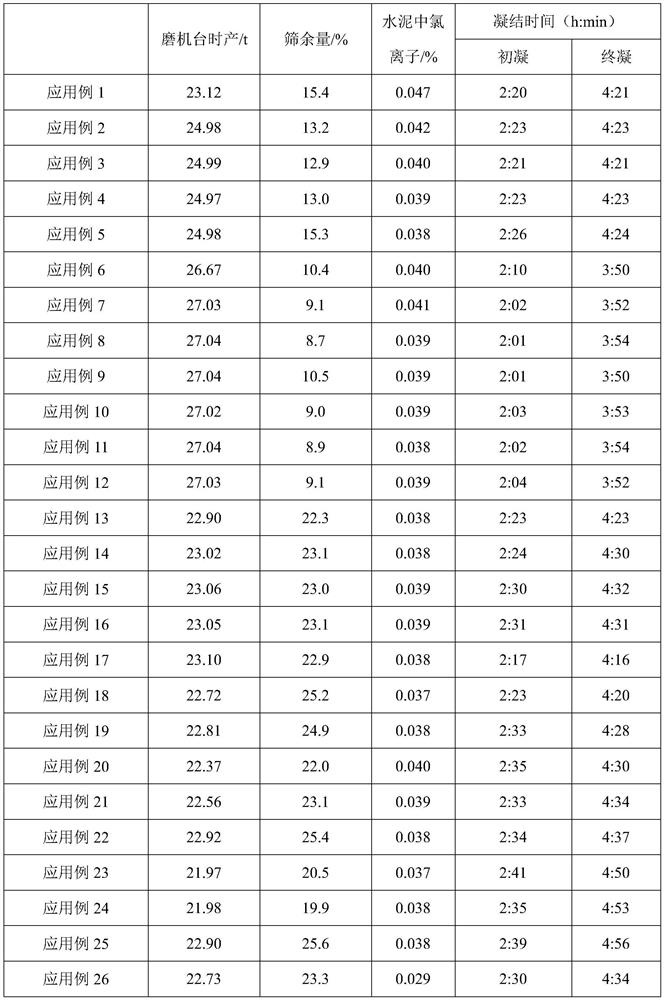

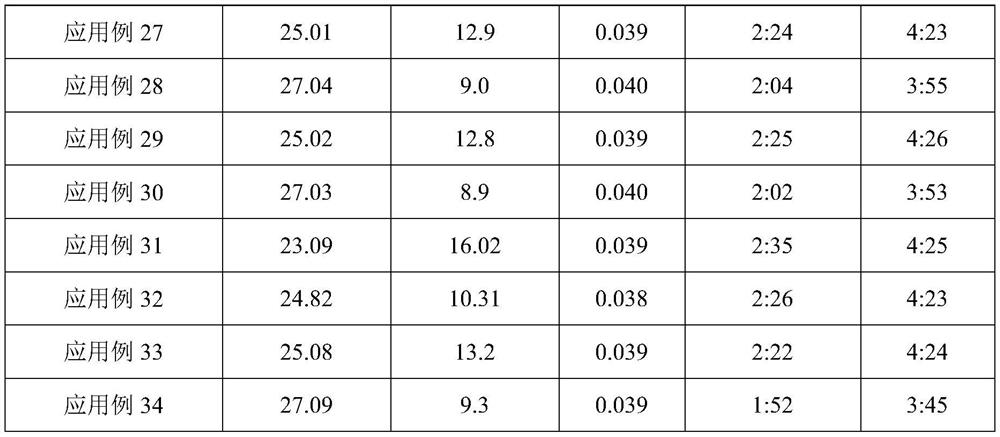

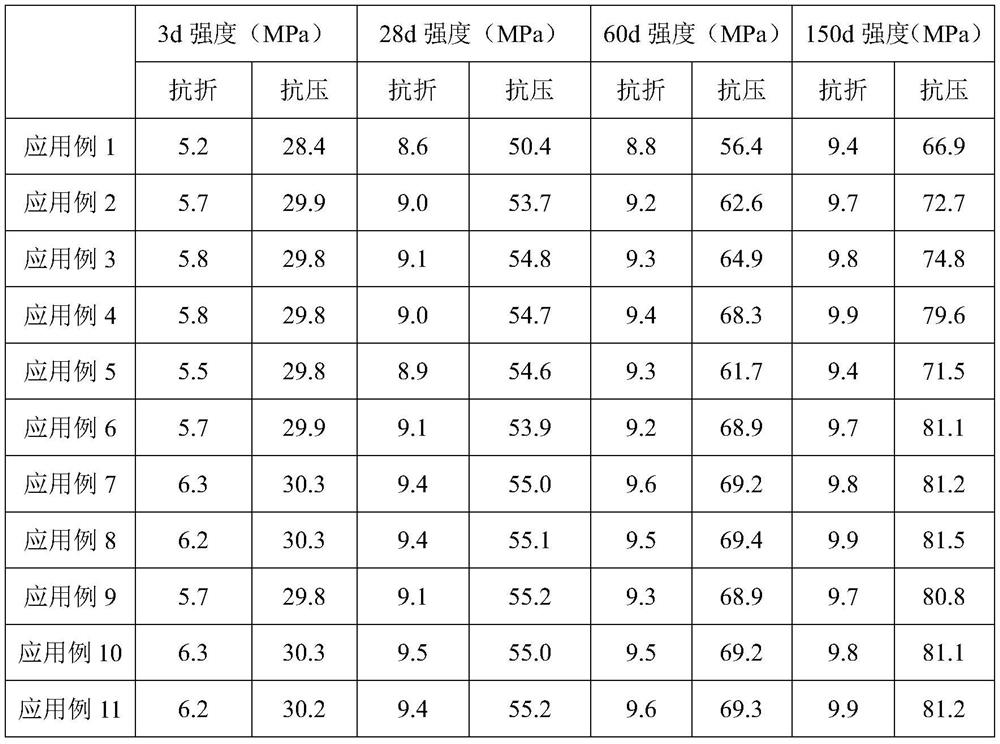

Examples

preparation example 1-3

[0034] A kind of carboxyl-terminated sodium hyperbranched polymer of preparation example 1-3, its each raw material and each raw material consumption thereof are as shown in table 1, and its preparation steps are as follows:

[0035] 1) Add 2-aminoterephthalic acid, triethanolamine, diisopropanolamine, n-propyl titanate and xylene into a three-necked flask, which is equipped with a water separator, condenser, thermometer and stirrer , slowly raised the temperature to 135°C, kept the temperature for 18 hours, and rotatively evaporated the xylene to obtain a carboxyl-terminated hyperbranched polymer;

[0036] 2) In 20 kg of water, add 3 kg of carboxy-terminated hyperbranched polymer and 0.1 kg of sodium hydroxide, stir and react for 30 min, evaporate and concentrate to obtain carboxy-terminated sodium hyperbranched polymer.

[0037] Each raw material of table 1 preparation example 1-3 terminal carboxyl hyperbranched polymer and each raw material consumption (kg)

[0038] ...

preparation example 4

[0040] The difference with Preparation Example 1 is that its preparation steps are as follows:

[0041] 1) Add 2-aminoterephthalic acid, triethanolamine, diisopropanolamine, n-propyl titanate and xylene into a three-necked flask, which is equipped with a water separator, condenser, thermometer and stirrer , slowly raise the temperature to 140°C, keep the temperature for 16 hours, and remove the xylene by rotary evaporation to obtain a carboxyl-terminated hyperbranched polymer;

[0042] 2) In 30 kg of water, add 2 kg of carboxy-terminated hyperbranched polymer and 0.15 kg of sodium hydroxide, stir and react for 20 min, evaporate and concentrate to obtain carboxy-terminated sodium hyperbranched polymer.

Embodiment 1-5

[0045] A kind of grinding aid that improves cement durability of embodiment 1-5, its each raw material and each raw material consumption are as shown in table 2, and its preparation steps are as follows:

[0046] Add triethanolamine, triisopropanolamine, diethanol monoisopropanolamine, and diethylene glycol into water, stir evenly, then add the remaining raw materials, stir evenly, and then the grinding aid can be obtained.

[0047] Each raw material of table 2 embodiment 1-5 grinding aid and each raw material consumption (kg)

[0048] Example 1 Example 2 Example 3 Example 4 Example 5 Triethanolamine 18 19 20 21 22 Triisopropanolamine 7.5 7 6.5 6 5.5 Diethanol monoisopropanolamine 0.5 1 1.7 2.5 3 Sodium chloride 4.5 4 3.5 3 2.5 diethylene glycol 0.5 1 1.7 2.5 3 Sodium acetate 6 5 4 3 2 water 63 63 62.6 62 62

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com