Formed foil for long-life aluminum electrolytic capacitor and preparation process thereof

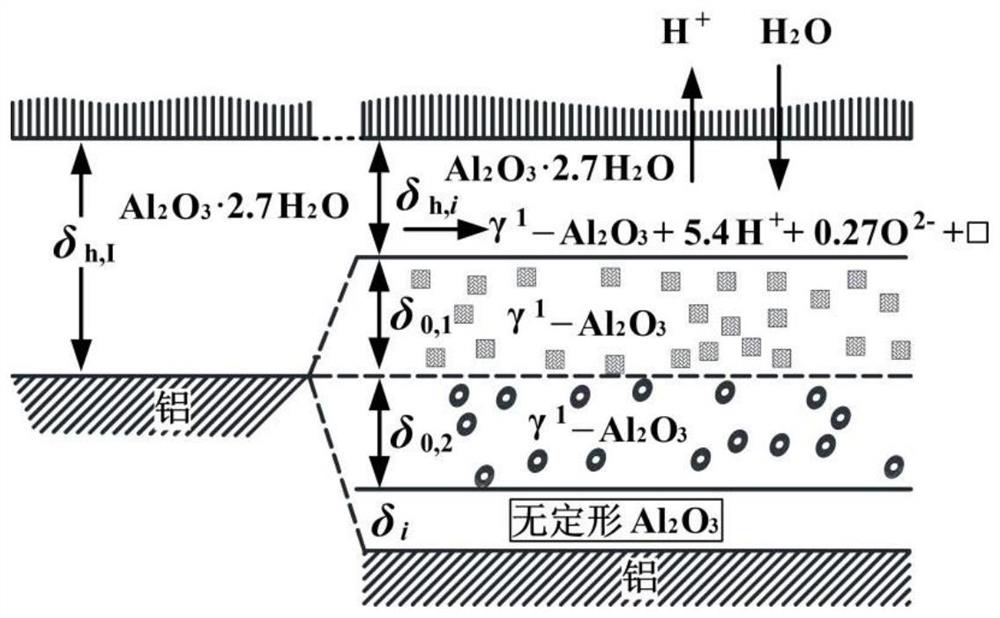

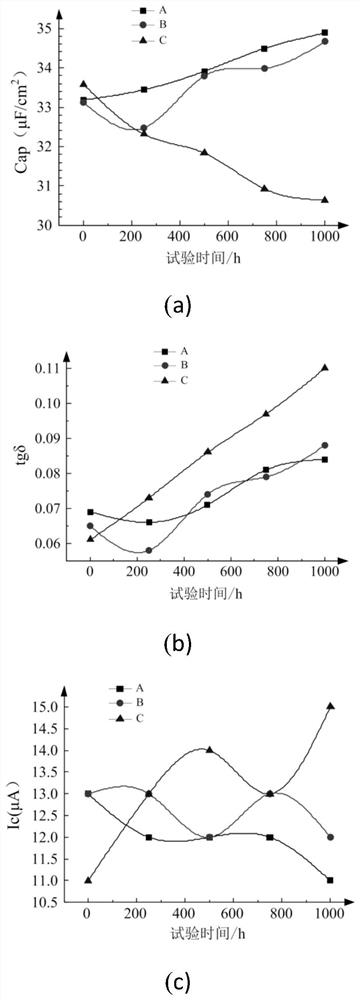

An aluminum electrolytic capacitor and its preparation technology are applied in the field of electrochemistry, which can solve the problems of shortened service life, capacitor failure, and large heat generation, and achieve the effects of prolonging life, reducing internal resistance and heat generation, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation process of formed foil for long-life aluminum electrolytic capacitors, the specific steps are:

[0048] S1. Preparation of porous membrane (pre-oxidized membrane)

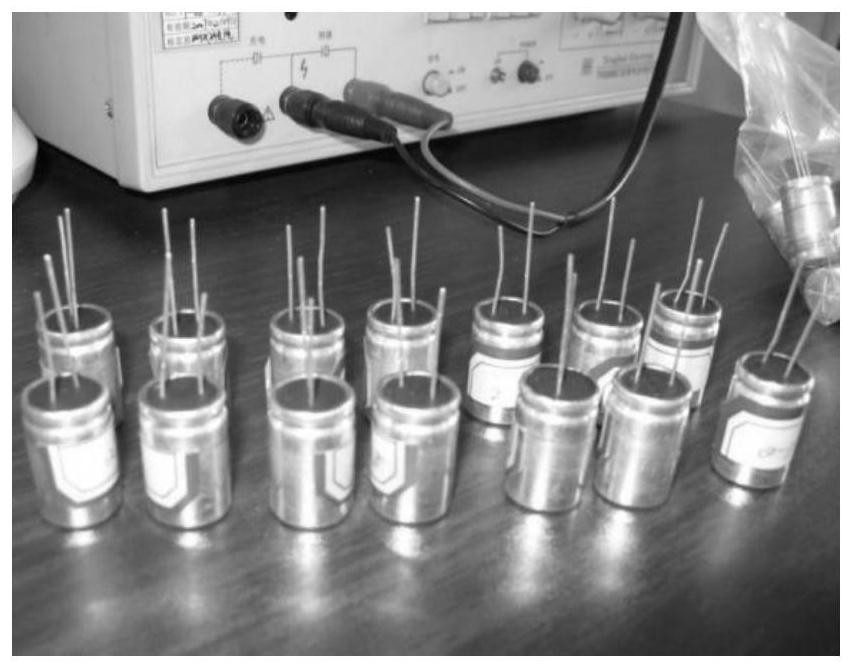

[0049] Use high-voltage corrosion foil for aluminum electrolytic capacitors, and cut into several foils with an area of 300×200. After the foil is washed with deionized water, it is connected to the positive pole of the DC power supply, and the opposite electrode is made of a stainless steel electrolytic cell to boost the voltage with a constant current (the current density is 6mA / cm 2 ) for anodizing. The electrolyte is prepared with 0.3 mol / L phosphoric acid aqueous solution and deionized water, and the resistivity of the deionized water is greater than 10MΩ.cm at a room temperature of 25°C. The oxidation temperature is 20°C, the oxidation time is 15 minutes, and the voltage is 15V, and several slices of parallel samples are prepared. After the anodized aluminum foil is taken out, it is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com