Composite transparent conductive film based on plant veins and preparation method thereof

A technology of transparent conductive film and conductive film, which is applied to equipment for manufacturing conductive/semiconductive layers, conductive layers on insulating carriers, and cable/conductor manufacturing. Problems such as high contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

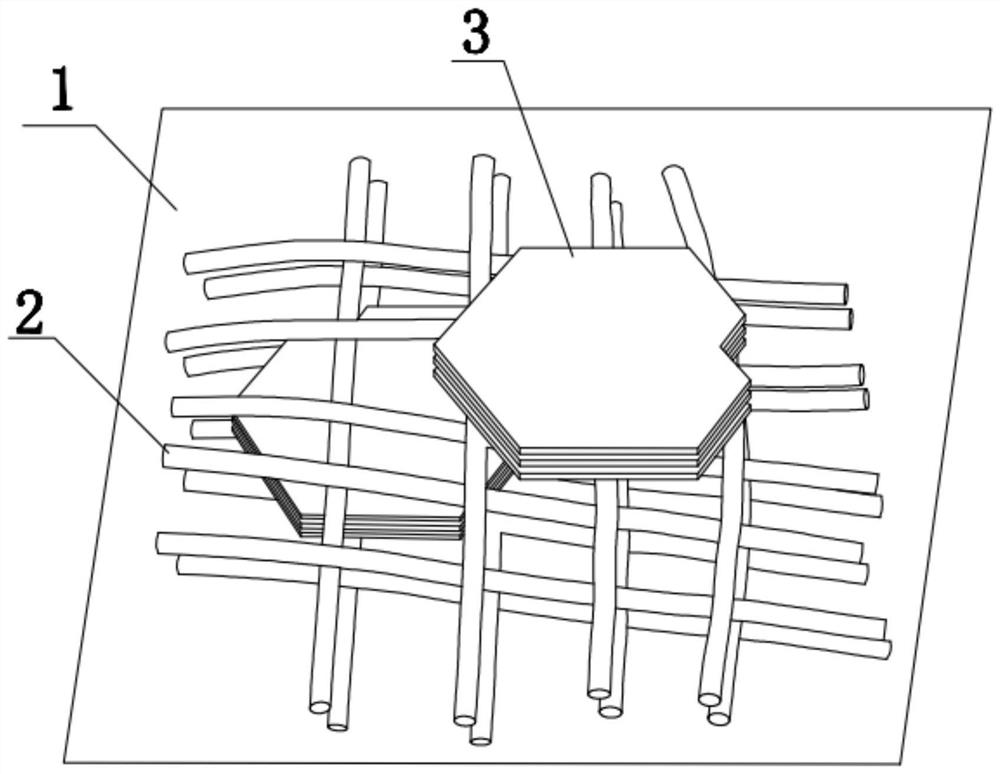

[0035] The composite transparent conductive film based on plant veins is a transparent conductive film formed by compounding plant veins 1 and silver nanowires 2-MXene3 by a deposition method.

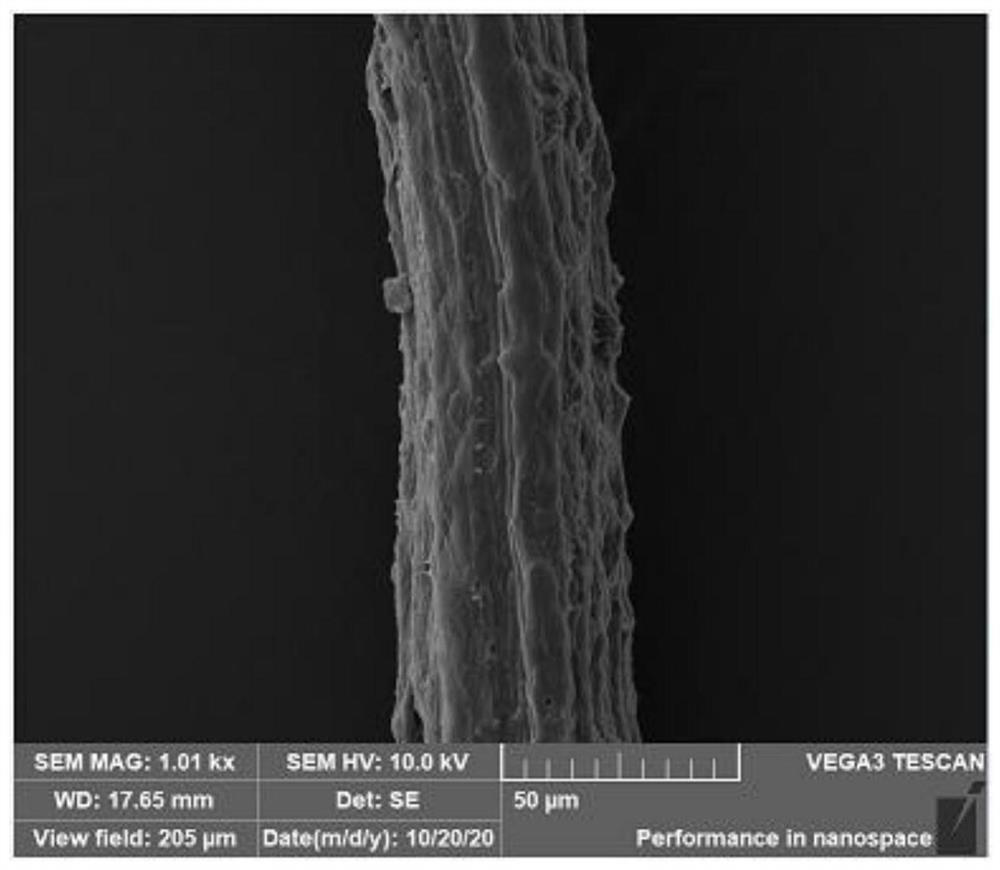

[0036] The silver nanowires have a diameter of 100 nm and a length of 40 μm.

[0037] The size of the MXene is 1 μm.

[0038] The above-mentioned preparation method of the composite transparent conductive film based on plant veins comprises the following steps:

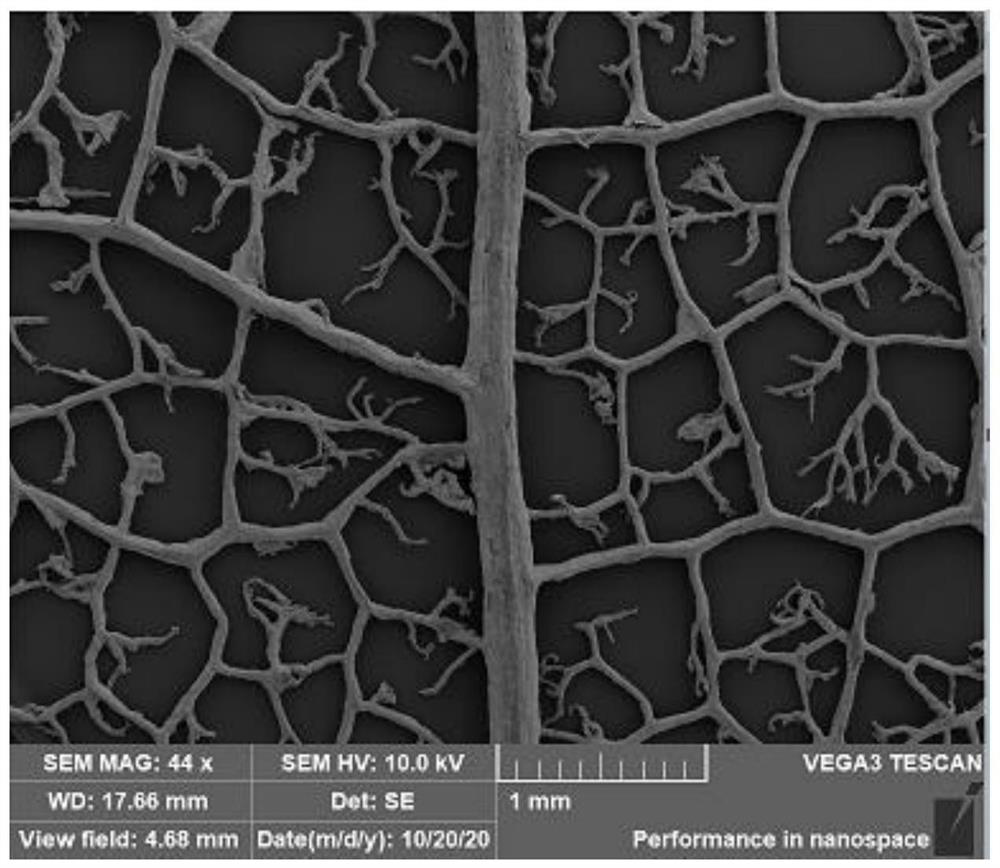

[0039] Step 1, using sodium hydroxide aqueous solution to etch the plant leaves, removing the mesophyll cells, washing with deionized water, and drying to obtain the plant vein base;

[0040] Step 2, flattening the plant vein base obtained in step 1 with a glass sheet to obtain a flat plant vein base;

[0041] Step 3, soaking the plant vein base obtained in step 2 in the silver nanowire ethanol solution and then drying to obtain the silver nanowire conductive layer, soaking the veins obtained in the silver nanowire conductive ...

Embodiment 2

[0051] The same part of this embodiment and embodiment 1 will not be repeated, and the difference is that the plant leaves in the step 1 are osmanthus leaves.

[0052] The square resistance of the transparent conductive film is 7.1 Ω / sq, the transmittance at 550 nm is 78%, and the resistance remains unchanged after being bent 100 times.

Embodiment 3

[0054] The same parts of this embodiment and embodiment 1 will not be repeated, the difference is that the diameter of the silver nanowire is 120 nm, and the length is 50 μm.

[0055] The size of the MXene is 3 μm.

[0056] In step 3, the drying temperature of the plant vein substrate after soaking in the silver nanowire ethanol solution is 60 ° C, and the drying time is 35 minutes, and the drying temperature of the vein of the silver nanowire conductive layer after soaking in the MXene solution is The temperature is 60°C, and the drying time is 35 minutes.

[0057] In step 1, the concentration of the aqueous sodium hydroxide solution is 0.15 g / ml.

[0058] In step 1, the temperature of the aqueous sodium hydroxide solution is 95° C., and the etching time is 2.5 hours.

[0059] In step 1, the drying temperature is 60° C., and the drying time is 35 minutes.

[0060] In step 3, the concentration of the silver nanowire ethanol solution is 3 mg / ml, and the concentration of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com