Silk fibroin/silicon dioxide composite material and preparation method thereof

A technology of silk fibroin and silicon dioxide, applied in medical science, prosthesis, etc., can solve the problems of lack of solution, small thickness, low stress, etc., and achieve the effect of excellent mechanical properties, low cost, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

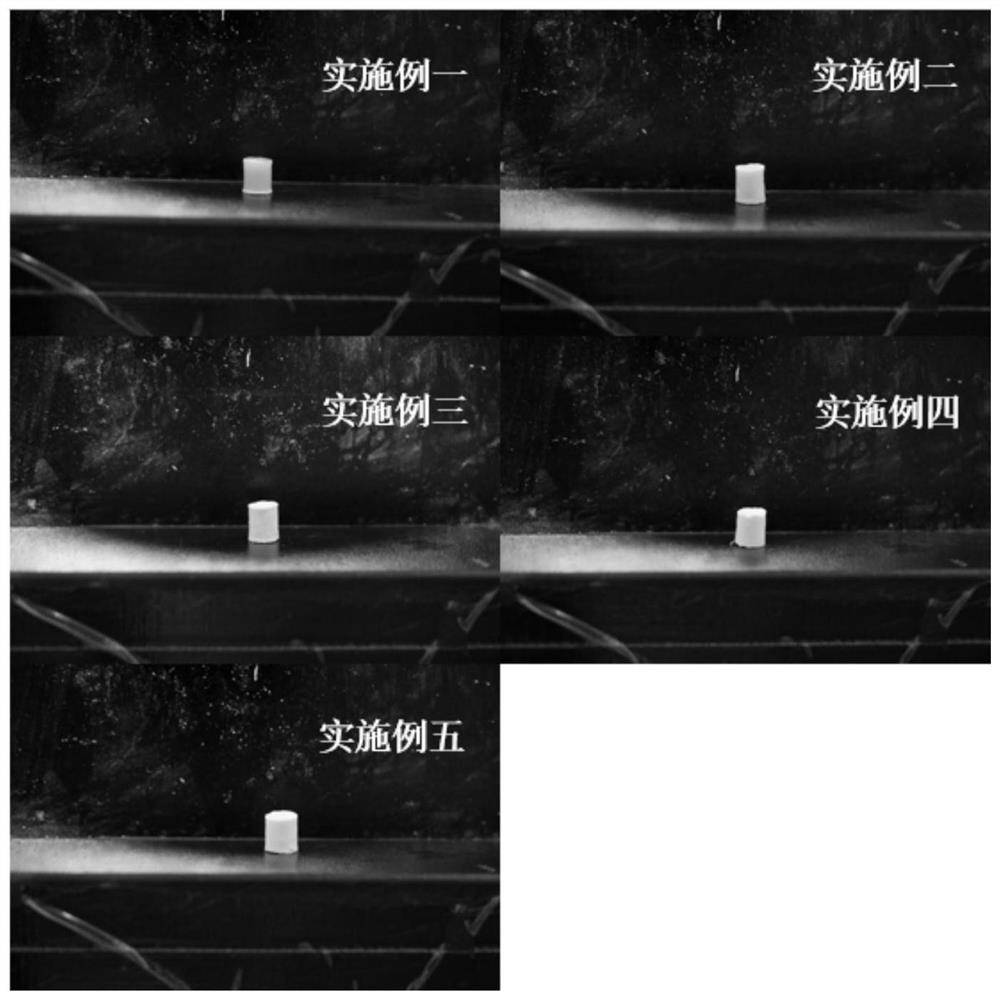

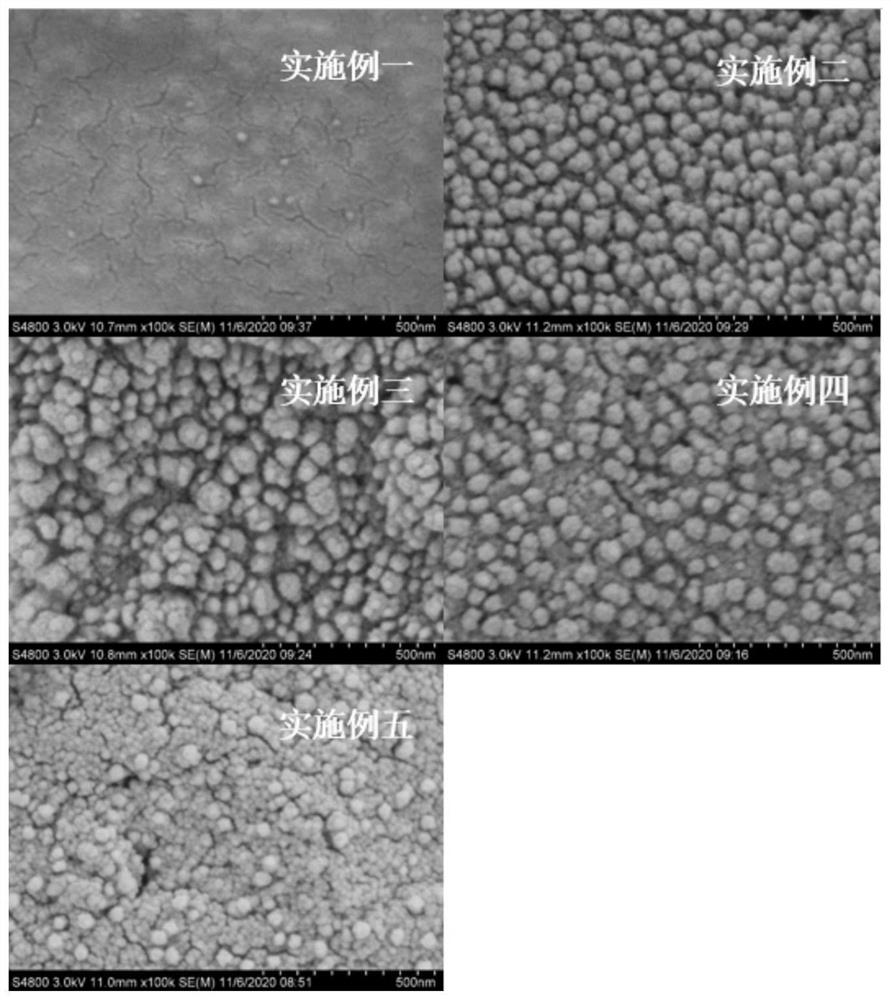

Examples

Embodiment 1

[0040] The preparation method of the silk fibroin / silica composite material of the present embodiment specifically includes the following steps;

[0041] (1) Preparation of silk fibroin solution

[0042] Weigh 3g NaHCO 3 and 1g Na 2 CO 3 Dissolve in 4000mL deionized water, heat to boiling, put in 80g silk, keep it at 98℃ for 30min, take it out and wash it in deionized water. After repeating the above steps three times, it was placed in an oven at 60° C. to dry to obtain silk fibroin fibers.

[0043] Prepare 9.3 mol / L LiBr solution, take 100 ml of lithium bromide solution and heat it to 65°C in a water bath, add 15 g of degummed silk fibroin in several times, stir to dissolve, and continue to heat and stir for 40 min. The liquid was placed in a dialysis bag and placed in deionized water for dialysis for 72 hours, and the deionized water was replaced every 2 hours. After dialysis, the solution was filtered to obtain a silk fibroin solution. Take a small amount of solution,...

Embodiment 2

[0059] The preparation method of the silk fibroin / silica composite material of the present embodiment specifically includes the following steps;

[0060] (1) Preparation of silk fibroin solution

[0061] The preparation method of the silk fibroin solution in this example is the same as that in Example 1, and will not be repeated here.

[0062] (2) Preparation of silica sol

[0063] Add tetraethyl orthosilicate to water so that the mass ratio of tetraethyl orthosilicate and water is 1:2, stir, add silk fibroin solution, make the mass content of silk fibroin in the system 0.1%, add a small amount of Ethanol, so that the mass content of ethanol in the system is 0.5%, and hydrochloric acid is added dropwise to the system to adjust the pH value to 2, then the system is heated to 50 ° C, and the reaction is stirred for 1 hour, until the system solution is clarified and no stratification occurs, obtaining two. Silica sol.

[0064] (3) Preparation of composite solution

[0065] Th...

Embodiment 3

[0077] The preparation method of the silk fibroin / silica composite material of the present embodiment specifically includes the following steps;

[0078] (1) Preparation of silk fibroin solution

[0079] The preparation method of the silk fibroin solution in this example is the same as that in Example 1, and will not be repeated here.

[0080] (2) Preparation of silica sol

[0081] Add tetraethyl orthosilicate to water so that the mass ratio of tetraethyl orthosilicate and water is 3:4, stir, add silk fibroin solution, make the silk fibroin content in the solution 0.1%, add a small amount of ethanol , the mass content of ethanol in the solution is 0.05%, and hydrochloric acid is added dropwise to the solution to adjust the pH value to 3, then the solution is heated to 55 ° C, and the reaction is stirred for 3 hours until the solution is clarified and does not stratify to obtain silicon dioxide sol.

[0082] (3) Preparation of composite solution

[0083] The silica sol prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com