Pole piece coating drying device and drying method

A drying device and pole piece technology, which is applied to the surface coating device, coating, pretreatment surface, etc., can solve the problem that the small increase in the size of the spot can not form a large area of the spot, and the uneven energy distribution of the spot , time difference between scanning positions and other issues, to achieve the effect of high drying and forming efficiency, small equipment footprint, and reduced divergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

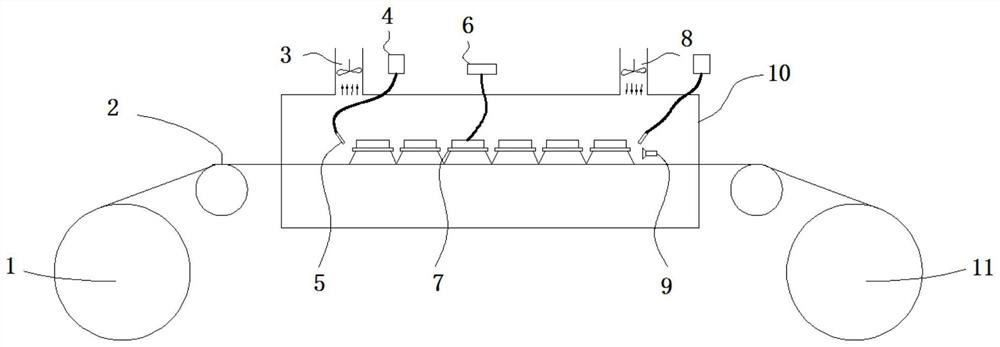

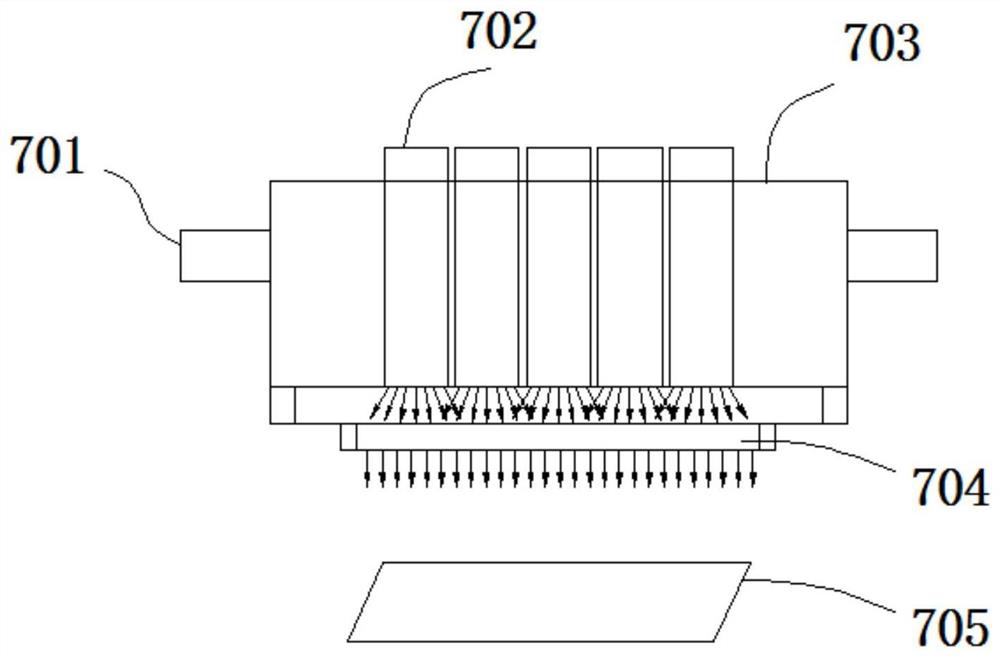

[0045] Such as figure 1 As shown, a pole piece coating drying device includes: an unwinding mechanism 1, used for unwinding the pole piece material roll; a pulley 2, used for transmitting the pole piece material roll at a uniform speed; an air outlet 3, used for discharging The gas keeps the air pressure balance in a dry environment; the data acquisition instrument 4 is used to collect the temperature data obtained by the infrared thermometer 5; the infrared thermometer 5 is used to measure the temperature on the surface of the pole piece material coil and detect the temperature change of the working surface; the power supply The module 6 is used to control the output power of the laser; the laser light source system 7 is used to output the laser of the specified wavelength; the air inlet 8 is used to input the dry gas without moisture to keep the environment clean; the blowing device 9 is used to make the volatilization The solvent moves along the airflow direction (opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com