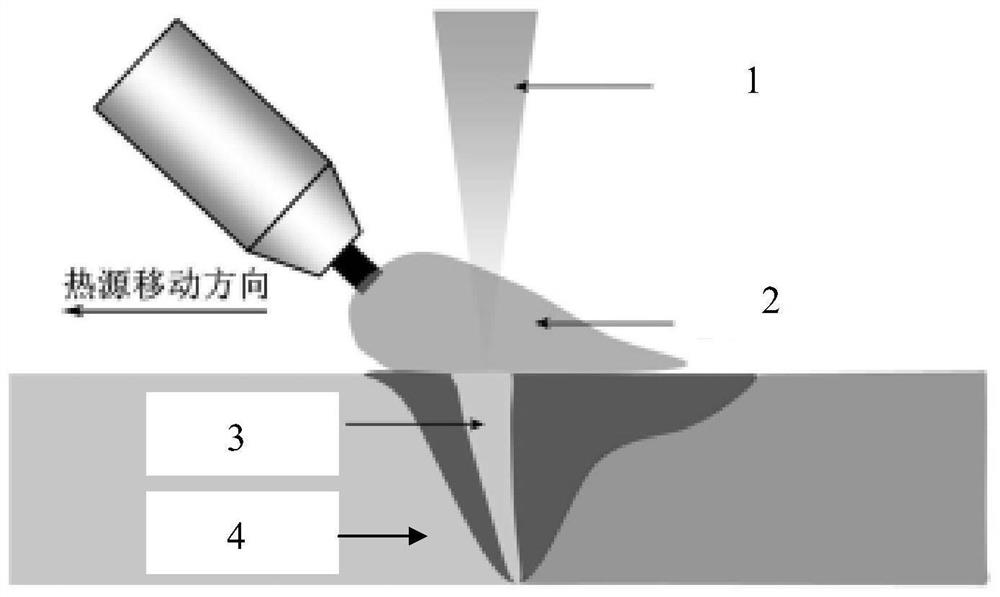

Efficient titanium alloy laser-electric arc composite heat source pipeline welding process

A technology of welding process and composite heat source, which is applied in laser welding equipment, welding equipment, metal processing, etc., can solve the problems of easy formation of undercut defects in welded joints, poor penetration ability of heat source energy, and reduce the safety factor of joints, etc., to achieve shortening The effect of engineering construction period, saving welding filling materials and improving welding production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Longitudinal seam welding of TA2 titanium alloy pipes with a wall thickness of 1 mm and a pipe diameter of φ110 mm

[0060] 1. Preparation before welding

[0061] (1) Check whether the surface of the workpiece is wet. If the surface of the workpiece is wet, wait for it to dry before welding;

[0062] (2) Clean the oil stains on the welding parts;

[0063] (3) The welding method and the selection of welding materials, the laser-TIG arc composite main method is selected for welding, and the purity of Ar gas is 99.99%.

[0064] 2. Spot welding

[0065] (1) According to the size of the welded structural parts, the length of spot welding is selected as 5mm;

[0066] (2) Pay attention to spot welding. The fixed width of spot welding shall not exceed 3mm. It should be a part of the future weld. When there is crack in the spot weld, it must be cut off and rewelded.

[0067] 3. Welding

[0068] For the I-shaped groove, the welding process without filler wire is s...

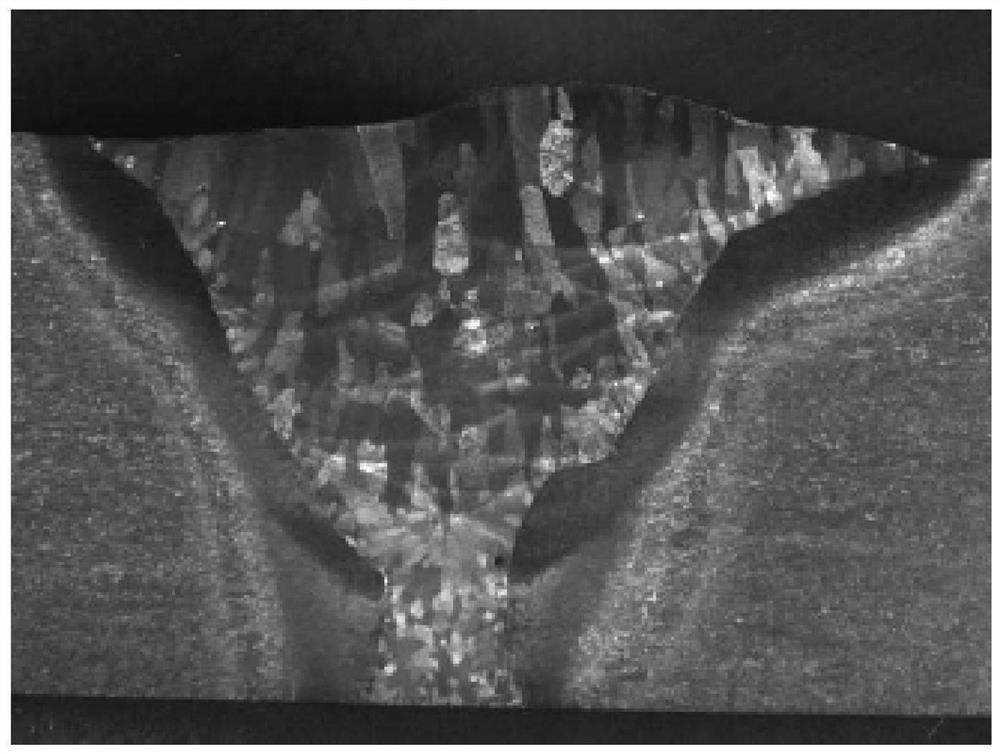

Embodiment 2

[0072] Example 2: Longitudinal seam welding of TC4 titanium alloy pipe with wall thickness 8mm and pipe diameter φ150mm

[0073] 1. Preparation before welding

[0074] (1) Groove processing, single side 20°, blunt side 2mm;

[0075] (2) Check whether the surface of the workpiece is wet. If the surface of the workpiece is wet, wait for it to dry before welding;

[0076] (3) Clean the oil stains on the welding parts;

[0077] (4) The welding method and the selection of welding materials, the laser-TIG arc composite main method is used for welding, and the purity of Ar gas is 99.99%.

[0078] 2. Spot welding

[0079] (1) According to the size of the welded structural parts, the length of spot welding is selected as 10mm;

[0080] (2) Pay attention to spot welding. The fixed height and width of spot welding shall not exceed 0.8mm and 3mm. It should be part of the future weld.

[0081] 3. Welding

[0082] Bottom welding: The welding process is arc current 240A, average laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com