Anti-restenosis 3D printing self-expansion degradable intravascular stent and preparation method thereof

A 3D printing, vascular stent technology, applied in coating, medical science, surgery, etc., can solve the problems of low biocompatibility of implanted biomaterials, hindering the long-term clinical success of interventional therapy, etc. Good elasticity and short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Such as Figure 5 As shown, a preparation method for anti-restenosis 3D printing self-expanding degradable vascular stent, comprising the following steps:

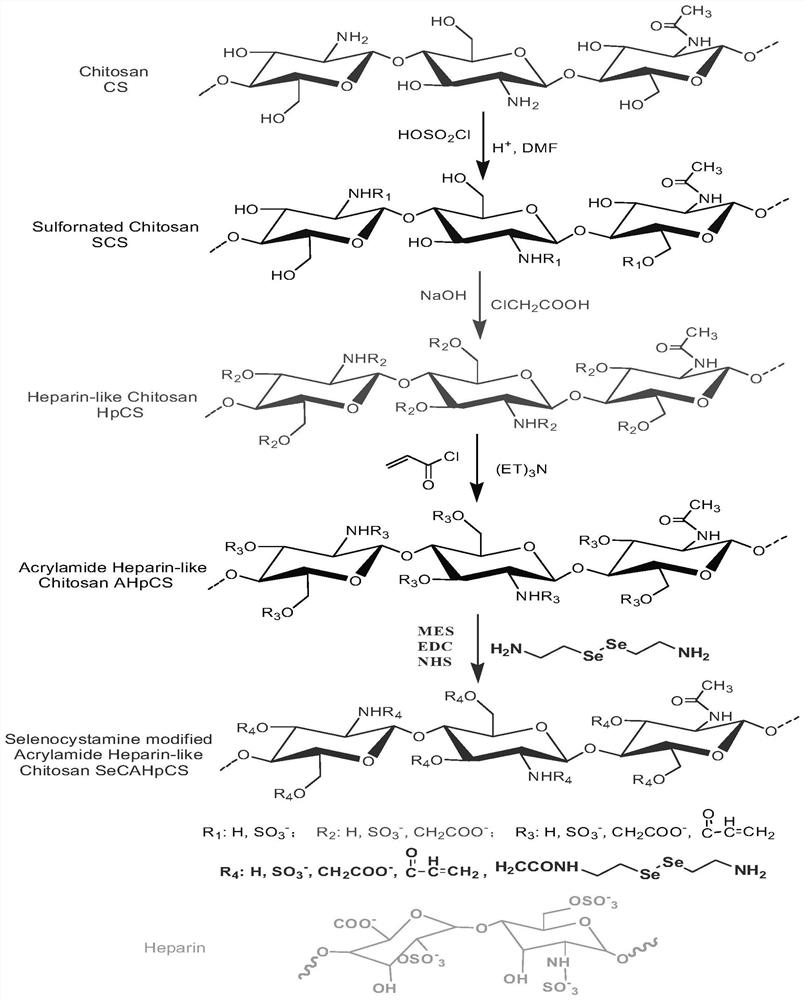

[0041] (1) Preparation of heparin-like / selenocystamine / acryloyl-modified chitosan: chitosan was mixed with chlorosulfonic acid, chloroacetic acid, and selenocystamine in sequence according to the molar ratio of 20:10:10:5:1 and acryloyl chloride reaction, wherein the molar mass of chitosan is calculated according to the molecular weight of the repeating unit of 161g / mol, and the hydroxyl and amino groups on the chitosan molecule are modified with sulfonic acid groups, carboxyl groups, selenocystamine groups and acryloyl groups, and regulated Grafting rate, prepared heparan / selenocystamine / acryloyl modified chitosan, the specific reaction formula is as follows figure 1 shown;

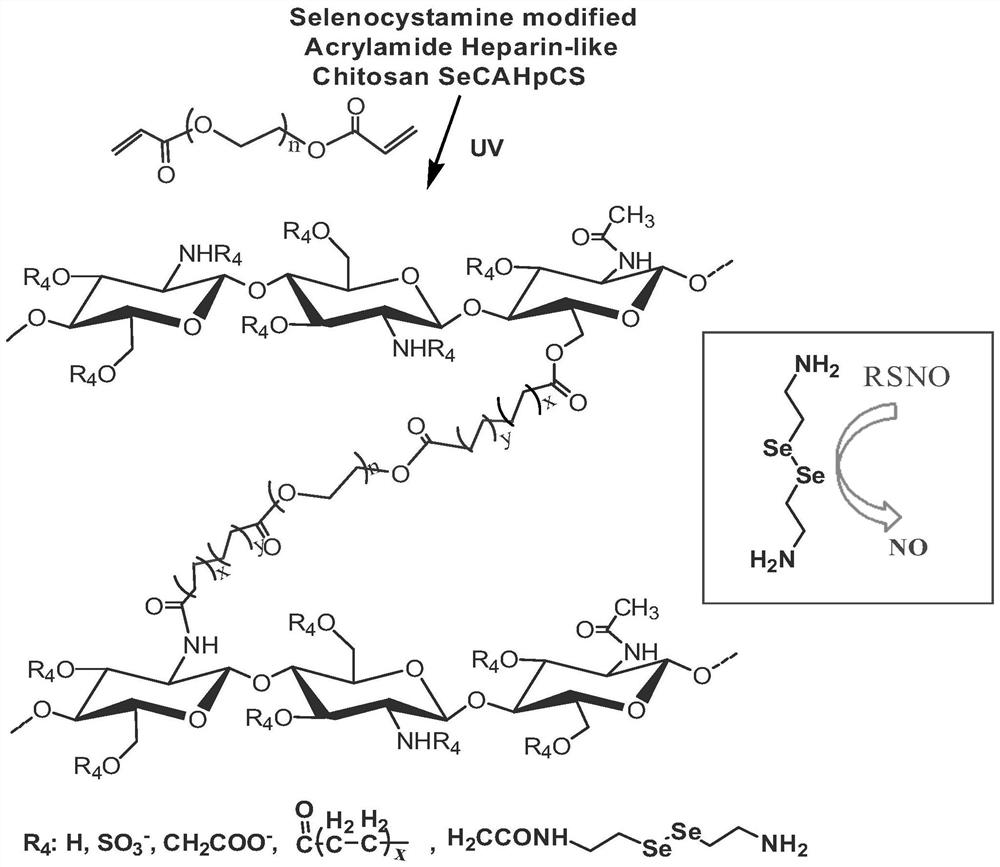

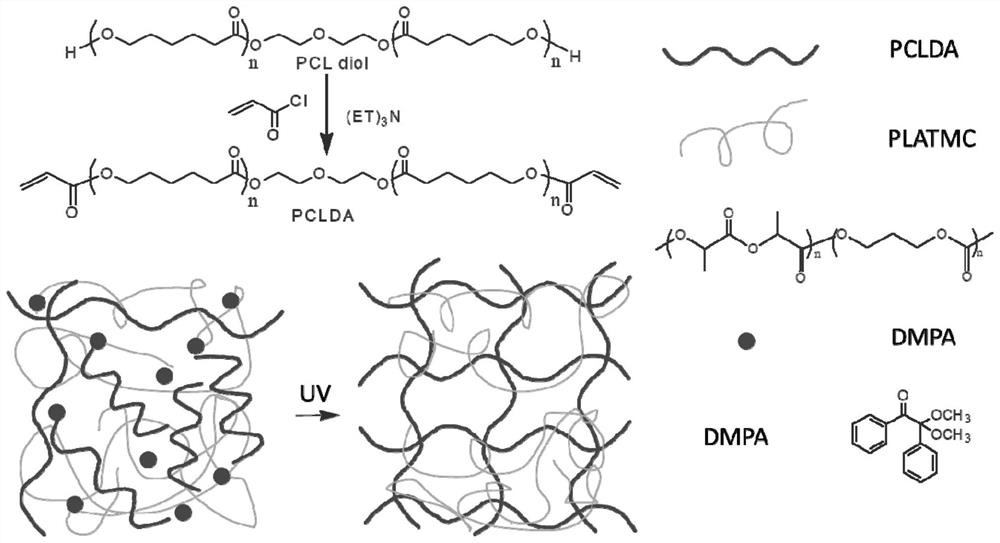

[0042] (2) Preparation of degradable hydrophilic layer 3D printing ink: the heparan / selenocystamine / acryloyl-modified chitosan obtained in...

Embodiment 2

[0046] Such as Figure 5 As shown, a preparation method for anti-restenosis 3D printing self-expanding degradable vascular stent, comprising the following steps:

[0047] (1) Preparation of heparin-like / selenocystamine / acryloyl-modified chitosan: Chitosan was mixed with chlorosulfonic acid, chloroacetic acid, and selenocystamine in sequence according to the molar ratio of 30:10:10:5:1 and acryloyl chloride reaction, wherein the molar mass of chitosan is calculated according to the molecular weight of the repeating unit of 161g / mol, and the hydroxyl and amino groups on the chitosan molecule are modified with sulfonic acid groups, carboxyl groups, selenocystamine groups and acryloyl groups, and regulated Grafting rate, prepared heparan / selenocystamine / acryloyl modified chitosan, the specific reaction formula is as follows figure 1 shown;

[0048] (2) Preparation of degradable hydrophilic layer 3D printing ink: the heparan / selenocystamine / acryloyl-modified chitosan obtained in...

Embodiment 3

[0052] Such as Figure 5 As shown, a preparation method for anti-restenosis 3D printing self-expanding degradable vascular stent, comprising the following steps:

[0053] (1) Preparation of heparin-like / selenocystamine / acryloyl-modified chitosan: Chitosan was sequentially mixed with chlorosulfonic acid, chloroacetic acid, and selenocystamine at a molar ratio of 15:10:10:5:1 and acryloyl chloride reaction, wherein the molar mass of chitosan is calculated according to the molecular weight of the repeating unit of 161g / mol, and the hydroxyl and amino groups on the chitosan molecule are modified with sulfonic acid groups, carboxyl groups, selenocystamine groups and acryloyl groups, and regulated Grafting rate, prepared heparan / selenocystamine / acryloyl modified chitosan, the specific reaction formula is as follows figure 1 shown;

[0054] (2) Preparation of degradable hydrophilic layer 3D printing ink: the heparan / selenocystamine / acryloyl-modified chitosan obtained in step (1), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com