Seed cutting device and method for casting single crystal superalloys with different crystal orientations

A technology of crystal orientation and seed crystal, applied in the field of mechanical processing, can solve the problems such as the inability to realize the cutting method of seed crystal with different crystal orientation, the low cost rate of seed crystal preparation, and the complexity of seed crystal preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

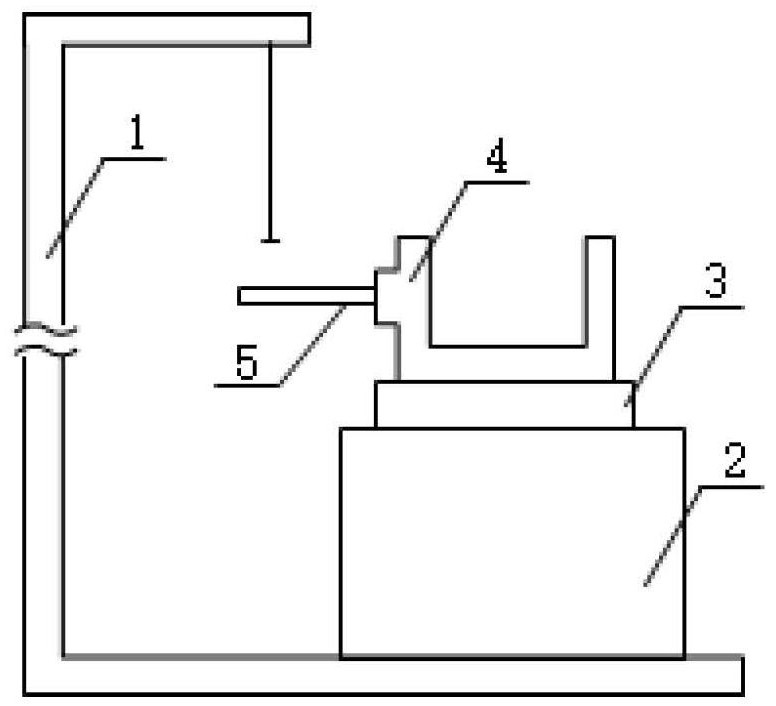

[0043] like figure 2 As shown, a seed crystal cutting device for casting single crystal superalloys with different crystal orientations consists of a bottom device 3 that controls and corrects the Gamma angle of the primary dendrite direction, and controls to correct the Delta angle of the primary dendrite direction and the Alpha angle of the secondary dendrite direction. The top device 4, the cutting machine 1 and the single crystal test rod 5 of the corner and the Beta angle are composed of; The combination is fixed, and the bottom device 3 and the top device 4 are located on the shelf 2 of the cutting machine 1;

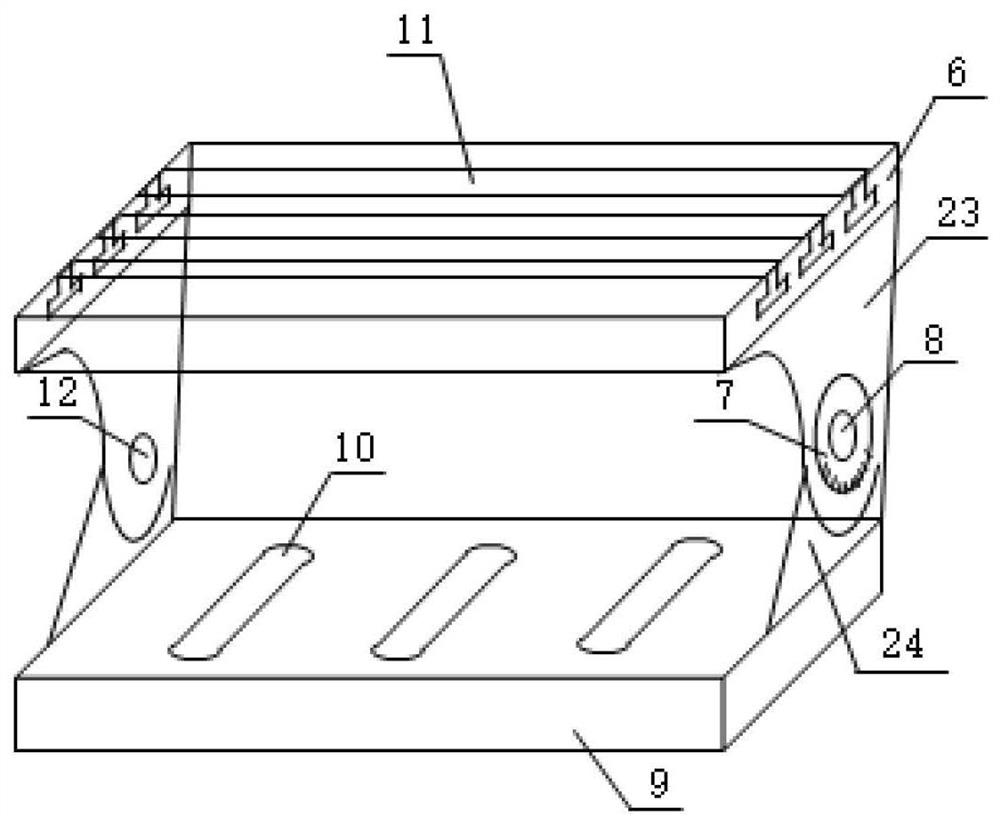

[0044] like image 3 As shown, the bottom device 3 includes a base 9 provided with three parallel slots I10, a fixed support plate 6 with three horizontal parallel slots II 11 above the base 9, and the angle of the Gamma angle in the primary dendrite direction is controlled to be corrected. The indexing plate 7 and the positioning bolts I 8 and II 12 connecting...

Embodiment 2

[0050] see figure 1 , a cutting method for a seed crystal cutting device for casting single crystal superalloys with different crystal orientations comprises the following steps:

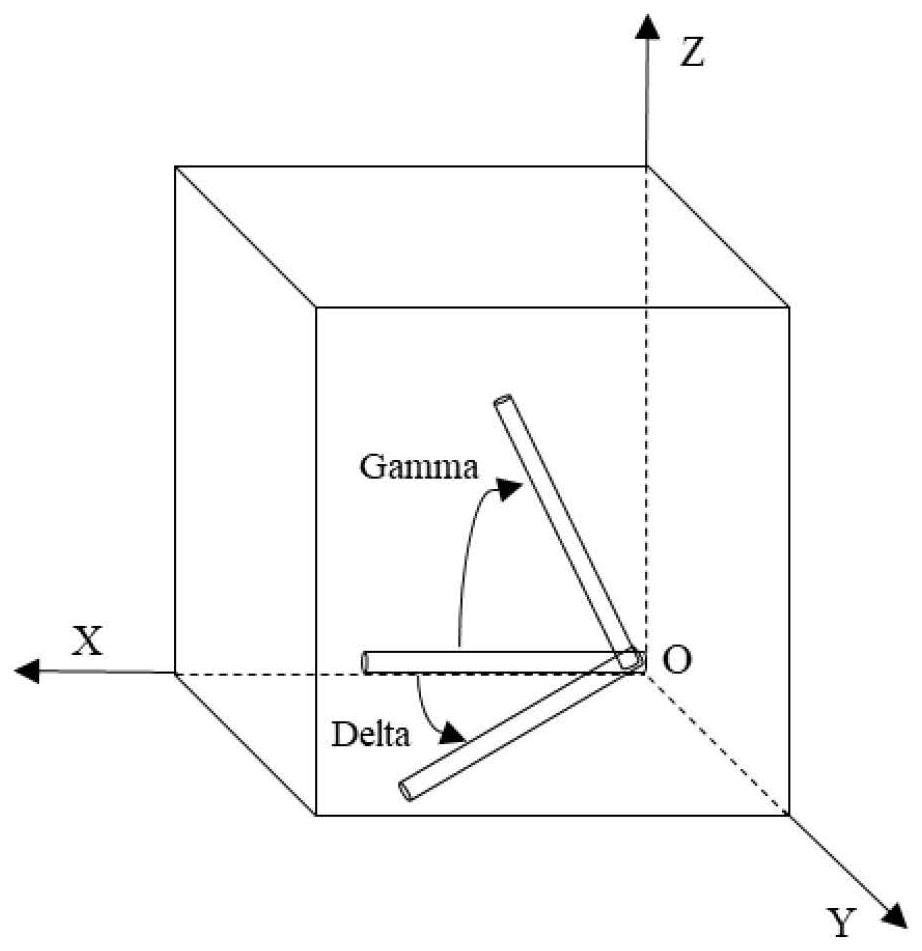

[0051] The first step is to measure the primary dendrite angle and secondary dendrite angle of the initial single crystal superalloy test bar used for seed crystal cutting by X-ray diffractometer, and obtain the corresponding primary dendrite direction Gamma angle and Delta angle, Alpha angle and Beta angle of secondary dendrite direction.

[0052] In the second step, the single crystal test rod 5 for seed crystal cutting is placed in the sample holder 15 of the top device 4 and clamped and fixed with bolts. The direction of the surface axis of the single crystal test rod 5 is recorded as the reference direction. Since the primary dendrite direction of the single crystal test rod is parallel to the crystallographic [001] direction, the crystal orientation can be determined according to the dendrite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com