Treatment method of BPA-containing sewage and ball-milling modified magnetic biochar composite material

A composite material and processing method technology, which is applied in the field of ball-milling modified magnetic biochar composite materials, can solve the problems of large surface fragmentation of ball-milling modified materials, increasing the difficulty and cost of preparing materials, and the existence of ecological health and safety risks. It is conducive to large-scale promotion, improved removal performance, and stable degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The treatment method that contains BPA sewage provided by the present embodiment, it may further comprise the steps:

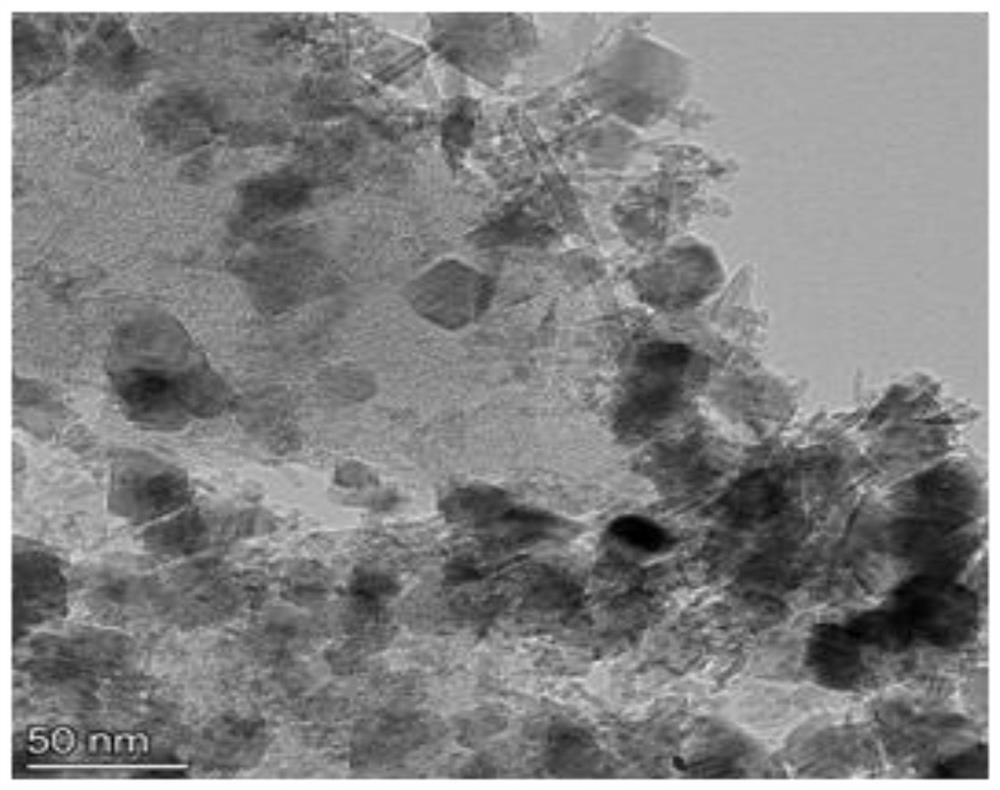

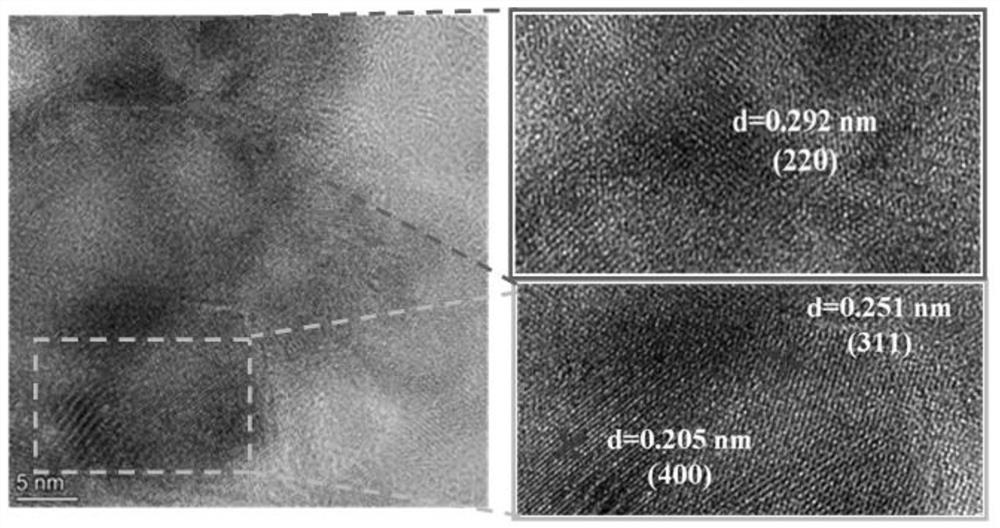

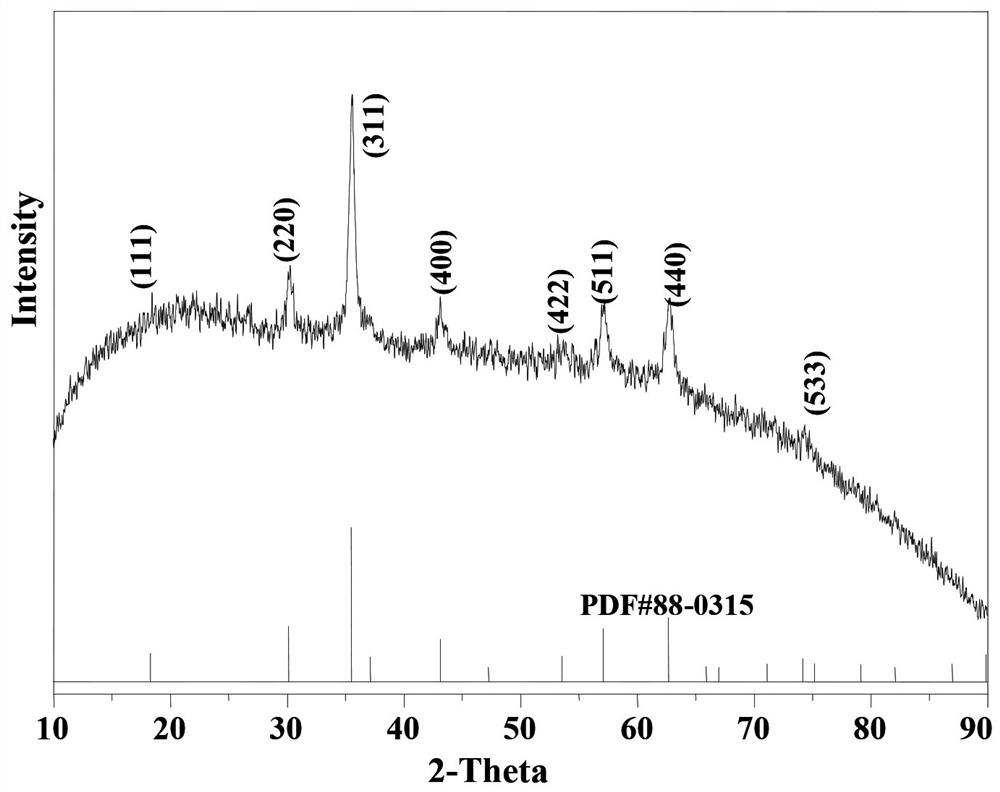

[0062] A) Preparation of ball-milled modified magnetic biochar composite Fe as a BPA-containing sewage remover 3 o 4 @MBC;

[0063] B) Obtain a BPA-containing sewage sample, and use high-performance liquid chromatography to determine the concentration of BPA in the sewage sample to be 20 mg / L;

[0064] C) The pH value of the detected sewage solution is 6.62, which is in the range of 3-9, and there is no need to adjust its pH value;

[0065] D) Adding PDS to achieve a concentration of 5 mM in the sewage sample, and then taking different proportions of ball-milled modified magnetic biochar composite material Fe 3 o 4 @MBC, respectively added to the sewage samples containing BPA, shaken in the shaking table for 3 hours, found that the removal rate corresponding to different concentration will change, the removal rate increases with Fe 3 o 4 The amount ...

Embodiment 2

[0098] See attached Figure 5 , the treatment method of BPA-containing sewage provided by the embodiments of the present invention, the ball-milling modified magnetic biochar composite material Fe 3 o 4 @MBC and its preparation method are basically the same as in Example 1, except that:

[0099] Obtain a sewage sample with a BPA concentration of 20mg / L. The pH value of the sample is 6.62. Fe 3 o 4 The concentration of @MBC is 0.5 g / L, and a certain amount of PDS is added to it to make the concentration in the sample change continuously, and the reaction is shaken in a shaking table for 3 hours, and the two can effectively remove BPA; when the concentration of PDS is 5mM , its removal process and effect are as follows Figure 5 As shown; the present embodiment tests by continuously changing the added concentration of PDS, and found that when the PDS concentration is 3 mM-9 mM, the effective removal of BPA can be realized, and the removal rate is greater than 91%, and the op...

Embodiment 3

[0106] See attached Figure 6 , the treatment method of BPA-containing sewage provided by the embodiments of the present invention, the ball-milling modified magnetic biochar composite material Fe 3 o 4 @MBC and its preparation method are basically the same as those in Examples 1 and 2, except that:

[0107] The step C) also includes the following steps:

[0108] C-1) When the pH value of the measured sewage sample solution is not within the range of 3-9, add 0.1-0.5 M acid (such as acetic acid, etc.) or alkaline compounds containing metal cations (such as NaOH, etc.) The pH of the sample was adjusted to 3-9, synergistically with Fe 3 o 4 @MBC material, catalyzes PDS, removes BPA in water.

[0109] Specifically, a sewage sample with a BPA concentration of 20 mg / L was obtained, the pH value of the sample was 11, and Fe 3 o 4 The concentration of @MBC is 0.5 g / L, the concentration of PDS is 5 mM, and then the pH regulator (acid or alkali) is added to adjust the pH value t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com