Polyurethane moisture curing agent high polymer material and production process thereof

A moisture curing agent and polymer material technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as hardness and adhesion defects, and achieve the effects of enhancing market competitiveness, improving hardness, and reducing spraying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

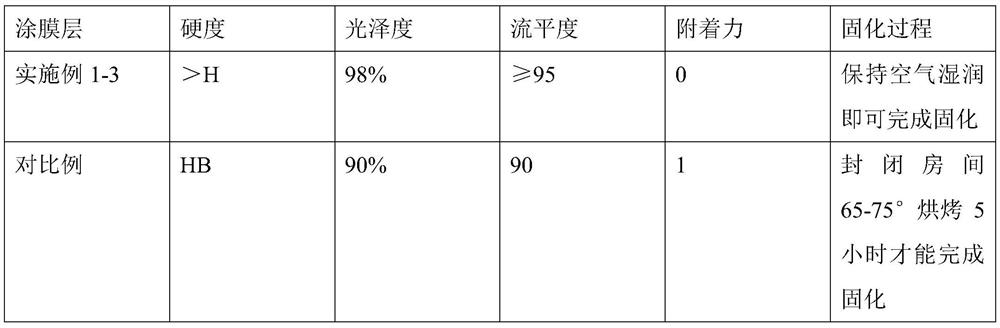

Examples

Embodiment 1

[0019] A production process of a polyurethane moisture curing agent macromolecular material comprises the following steps: 1) Input raw materials: add toluene diisocyanate, butyl acetate, fatty acid resin, polyester polyol in a ratio of 6:4.5:1:1.5, stir, Raise the temperature to 66°C, keep it warm for 2 hours, and then add antioxidant; 2) Cool down and keep the temperature at 54°C, add one-half of the total amount of trimethylolpropane, and then add the remaining half after 20 minutes The amount of trimethylolpropane, raise the temperature to 64°C within 25min, and keep it warm for 2h; 3) keep it at 64°C, add one-half of the total amount of polyether polyol, keep warm for 30min, and then add the remaining half A certain amount of polyether polyol continues to react for 1.5h, while adding polyether polyol each time, add butyl acetate; 4) cool down and control the temperature to keep at 55°C, add diethylene glycol, and simultaneously add butyl acetate Ester, heat preservation r...

Embodiment 2

[0022] A production process of a polyurethane moisture curing agent macromolecular material comprises the following steps: 1) Input raw materials: add toluene diisocyanate, butyl acetate, fatty acid resin, polyester polyol in a ratio of 6:4.5:1:1.5, stir, Raise the temperature to 66°C, keep it warm for 2 hours, and then add antioxidant; 2) Cool down and keep the temperature at 54°C, add one-half of the total amount of trimethylolpropane, and then add the remaining half after 20 minutes The amount of trimethylolpropane, raise the temperature to 64°C within 25min, and keep it warm for 2h; 3) keep it at 64°C, add one-half of the total amount of polyether polyol, keep warm for 30min, and then add the remaining half A certain amount of polyether polyol continues to react for 1.5h, while adding polyether polyol each time, add butyl acetate; 4) cool down and control the temperature to keep at 55°C, add diethylene glycol, and simultaneously add butyl acetate Ester, heat preservation r...

Embodiment 3

[0025] The difference between this embodiment and Example 1 is that the components of the polyurethane moisture curing agent polymer material are as follows: 610 parts of toluene diisocyanate, 550 parts of butyl acetate, 110 parts of fatty acid resin, 160 parts of polyester polyol, antioxidant 5 parts, 105 parts of trimethylolpropane, 410 parts of polyether polyol, 50 parts of diethylene glycol, 12 parts of n-butanol, 5 parts of silicone type leveling agent, 3.5 parts of polymer type leveling agent, polymer Type defoamer 1.2 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com