Curing agent resistant to complex and harmful ion coupling environment and preparation method and application thereof

A technology of curing agent and ions, which is applied in the field of building material additives, can solve the problems of cement expansion, mechanical property decline, unsuitable application, etc., and achieve the effects of strong adsorption capacity, improved mechanical properties, and convenient material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

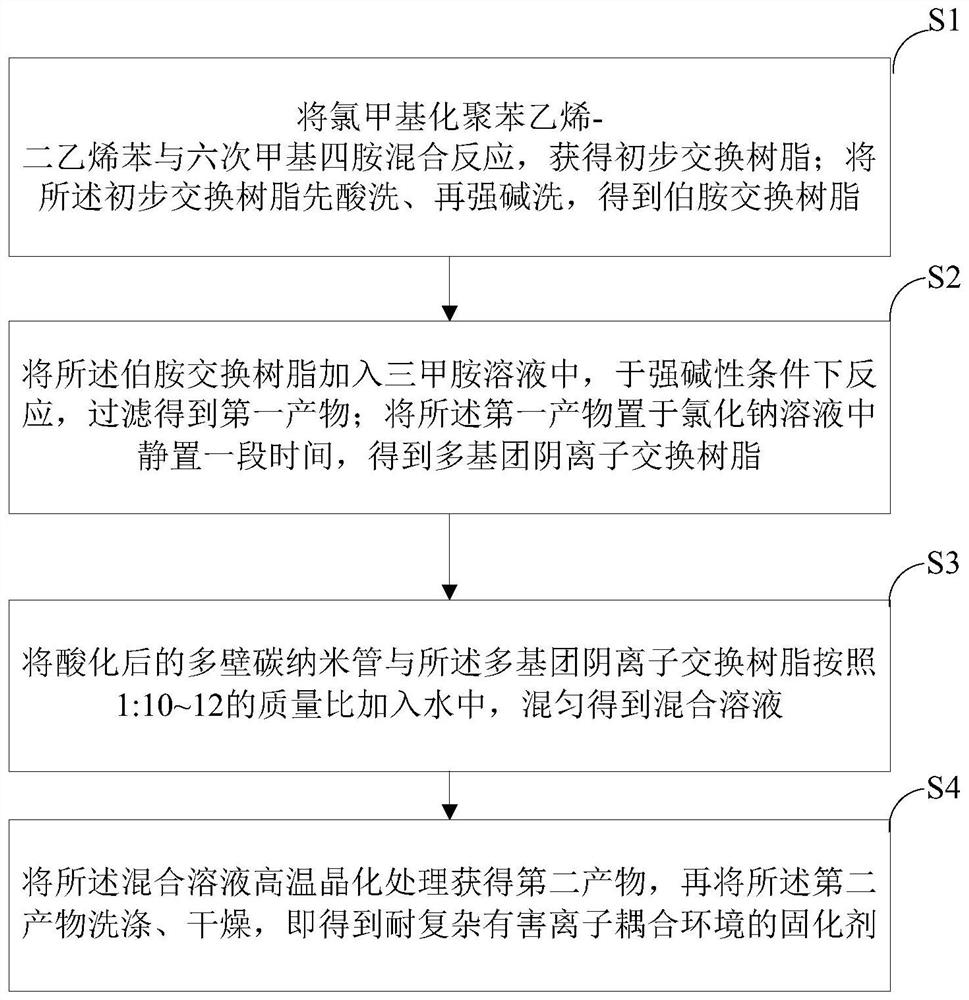

[0043] A preparation method of a curing agent resistant to complex and harmful ion coupling environment:

[0044] Step 1: After the chloromethylated polystyrene-divinylbenzene is swollen in a mixed solution of absolute ethanol and chloroform for 6 hours, it is stirred with hexamethylenetetramine at a mass ratio of 1:1 at 40 ° C for 6 hours, After the reaction is complete, wash with absolute ethanol to obtain a preliminary exchange resin; add the preliminary exchange resin into concentrated hydrochloric acid (the mass ratio of preliminary exchange resin and hydrochloric acid is 1:12) and stir for 3h, then filter and wash the resin and add strong oxidation Keep PH>14 in the sodium solution, transform the exchange resin for 2h, wash and filter with water to obtain the primary amine exchange resin;

[0045] Step 2: Add the primary amine exchange resin into a 70% trimethylamine solution (the mass ratio of primary amine resin:trimethylamine solution is 1:25), add NaOH solution at th...

Embodiment 2

[0049] A preparation method of a curing agent resistant to complex and harmful ion coupling environment:

[0050] Step 1: After the chloromethylated polystyrene-divinylbenzene is swollen in a mixed solution of absolute ethanol and chloroform for 8 hours, it is stirred with hexamethylenetetramine at a mass ratio of 1:1.2 at 45 ° C for 8 hours, After the reaction is complete, wash with absolute ethanol to obtain a preliminary exchange resin; add the preliminary exchange resin into concentrated hydrochloric acid (the mass ratio of preliminary exchange resin and hydrochloric acid is 1:15) and stir for 5h, then filter and wash the resin and add strong oxidation Keep pH>14 in the sodium solution, transform the exchange resin for 4h, wash and filter with water to obtain the primary amine exchange resin;

[0051] Step 2: Add the primary amine exchange resin into 50% trimethylamine solution (the mass ratio of primary amine resin:trimethylamine solution is 1:30), add NaOH solution at th...

Embodiment 3

[0055] A preparation method of a curing agent resistant to complex and harmful ion coupling environment:

[0056] Step 1: After the chloromethylated polystyrene-divinylbenzene is swollen in a mixed solution of absolute ethanol and chloroform for 7 hours, it is stirred with hexamethylenetetramine at a mass ratio of 1:1.1 at 30 ° C for 7 hours, After the reaction is complete, wash with absolute ethanol to obtain a preliminary exchange resin; add the preliminary exchange resin to concentrated hydrochloric acid (the mass ratio of preliminary exchange resin and hydrochloric acid is 1:14) and stir for 4h, then filter and wash the resin and add strong oxidation Keep PH>14 in the sodium solution, transform the exchange resin for 3h, wash and filter with water to obtain the primary amine exchange resin;

[0057] Step 2: Add the primary amine exchange resin into 65% trimethylamine solution (the mass ratio of primary amine resin:trimethylamine solution is 1:28), add NaOH solution at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com