Ultraviolet-moisture double-curing modified silicone adhesive and preparation method thereof

A technology of silicone adhesive and ultraviolet light, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem that polysiloxane cannot be used directly, achieve good high and low temperature resistance, improve Physical and chemical properties, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, a method for preparing a UV-moisture dual-curing modified silicone adhesive comprises the following steps:

[0044] (1) Preparation of modified polysiloxane:

[0045] At 80°C, while stirring, 15.0 g of acrylic acid and 15.0 g of acrylic acid and A mixed solution composed of 0.75g triethylamine; after the dropwise addition, the temperature was raised to 100°C, and after 4 hours of heat preservation reaction, the unreacted acrylic acid was distilled off under reduced pressure; the temperature was readjusted to 75°C, and 10.0g was added dropwise while stirring 3-isocyanatopropyltrimethoxysilane, heat preservation reaction for 3 hours, cooling to obtain modified polysiloxane. The above reactions were all carried out in a nitrogen atmosphere.

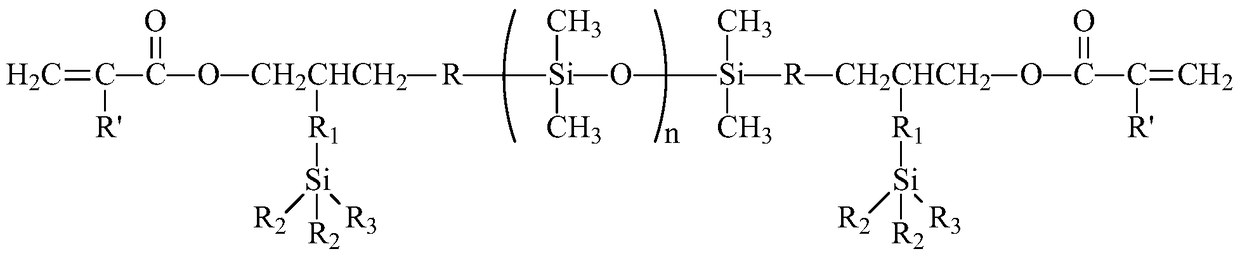

[0046] Prepare the structural formula of modified polysiloxane as follows:

[0047]

[0048] Wherein, n=400~500, n is an integer; the viscosity of the product is about 1600mPa·S.

[0049] (2) Preparation of si...

Embodiment 2

[0052] In this embodiment, a method for preparing a UV-moisture dual-curing modified silicone adhesive comprises the following steps:

[0053] (1) Preparation of modified polysiloxane:

[0054] At 80°C, while stirring, 15.0 g of acrylic acid and 15.0 g of acrylic acid and A mixed solution composed of 0.75g triethylamine; after the dropwise addition, the temperature was raised to 100°C, and after 4 hours of heat preservation reaction, the unreacted acrylic acid was distilled off under reduced pressure; the temperature was readjusted to 75°C, and 10.0g was added dropwise while stirring 3-isocyanatopropyl triethoxysilane, heat preservation reaction for 3 hours, cooling to obtain modified polysiloxane. The above reactions were all carried out in a nitrogen atmosphere.

[0055] Prepare the structural formula of modified polysiloxane as follows:

[0056]

[0057] Wherein, n=650~700, n is an integer; the viscosity of the product is about 5000mPa·S.

[0058] (2) Preparation of ...

Embodiment 3

[0061] In this embodiment, a method for preparing a UV-moisture dual-curing modified silicone adhesive comprises the following steps:

[0062] (1) Preparation of modified polysiloxane:

[0063] At 80°C, while stirring, add 15.0 g of methacrylic acid dropwise to a reactor containing 1000 g of diepoxy-terminated polydimethylsiloxane with a viscosity of 10 Pa·S and 4.0 g of hydroquinone and 0.75g triethylamine; after the dropwise addition, the temperature was raised to 100°C, and after the heat preservation reaction for 4 hours, the unreacted acrylic acid was distilled off under reduced pressure; the temperature was readjusted to 75°C, and 10.0 g 3-isocyanatopropyltriethoxysilane, heat preservation reaction for 3 hours, and cool to obtain modified polysiloxane. The above reactions were all carried out in a nitrogen atmosphere.

[0064] Prepare the structural formula of modified polysiloxane as follows:

[0065]

[0066] Wherein, n=800~900, n is an integer; the viscosity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com