Novel chrysanthemum charcoal processing technology

A processing technology and chrysanthemum technology, which is applied in the field of new chrysanthemum charcoal processing technology, can solve the problems of poor quality, limited raw materials and high cost, and achieve the effects of large weight, lower price and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

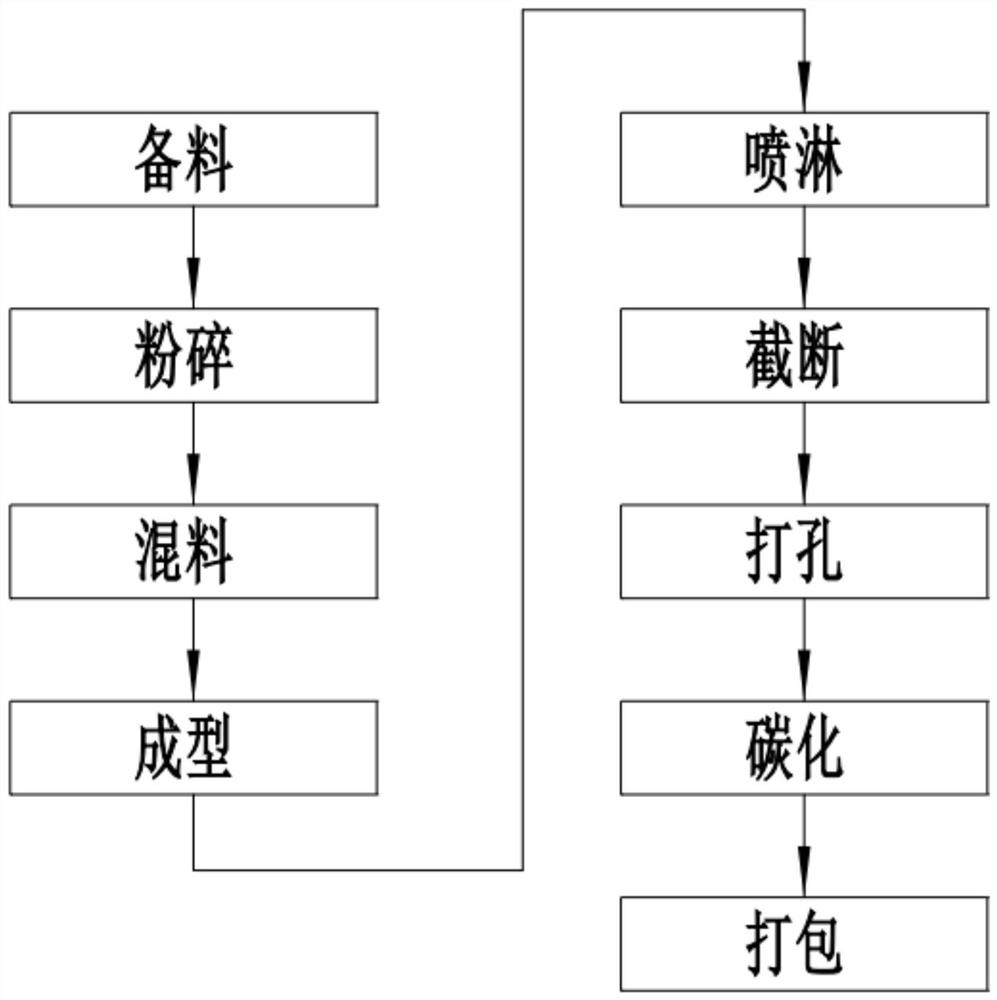

[0037] A novel chrysanthemum charcoal processing technology, comprising the following steps:

[0038] S1. Material preparation: select plant raw materials as raw materials, remove sundries from the plant raw materials, and then dry them for later use;

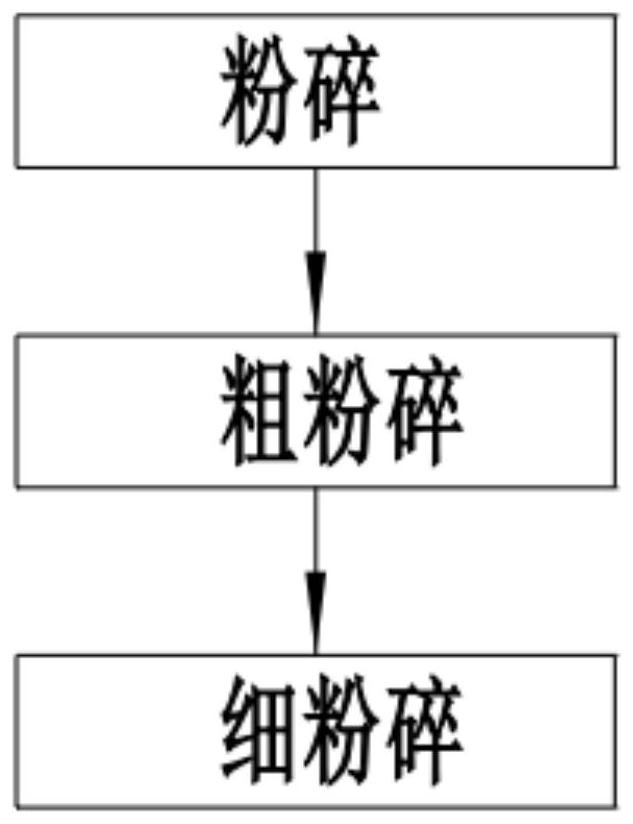

[0039] S2. Pulverization: put the dried wood in S1 into the coarse pulverizer and the fine pulverizer in turn for pulverization, and pass through a 200-mesh screen to remove larger particles;

[0040] S3. Mixing: Put the wood particles in S2 into the mixing tank and add water to stir, add carbon powder binder while stirring, stop adding water and continue stirring for 1 hour when the mixture is loose;

[0041] S4. Molding: put the mixed material stirred in S3 into the molding machine for extrusion molding, and cool the shaped wood to room temperature;

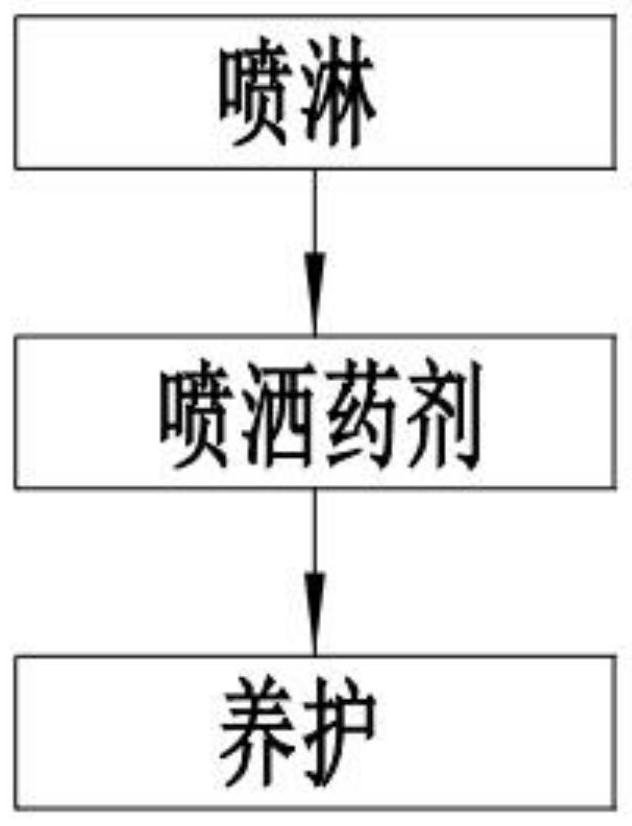

[0042] S5. Spraying: Spray the laminated wood in S4 with chemicals, and wrap it with plastic wrap for 5 hours for maintenance;

Embodiment 2

[0057] A novel chrysanthemum charcoal processing technology, comprising the following steps:

[0058] S1. Material preparation: select plant raw materials as raw materials, remove sundries from the plant raw materials, and then dry them for later use. One or more of wood chips, shavings, pine shells, and coconut shells are mixed, so that the raw materials are not limited. The drying time of plant raw materials is 2 days, and the moisture content of plant raw materials is 12%, so that the crushed plant raw materials Better results;

[0059] S2. Crushing: Put the dried wood in S1 into the coarse grinder and fine grinder for grinding, and pass through a 200-mesh screen to remove larger particles. First, use the coarse grinder to coarsely grind the plant material once , and then use a fine pulverizer to pulverize 3 times;

[0060] S3. Mixing: put the wood particles in S2 into the mixing tank and add water to stir, add carbon powder binder while stirring, stop adding water when t...

Embodiment 3

[0068] A novel chrysanthemum charcoal processing technology, comprising the following steps:

[0069] S1. Material preparation: select plant raw materials as raw materials, remove sundries from the plant raw materials, and then dry them for later use. One or more of wood chips, shavings, pine shells, and coconut shells are mixed, so that the raw materials are not limited. The drying time of plant raw materials is 2 days, and the moisture content of plant raw materials is 12%, so that the crushed plant raw materials Better results;

[0070] S2. Crushing: Put the dried wood in S1 into the coarse grinder and fine grinder for grinding, and pass through a 200-mesh screen to remove larger particles. First, use the coarse grinder to coarsely grind the plant material once , and then use a fine pulverizer to pulverize 3 times;

[0071] S3. Mixing: put the wood particles in S2 into the mixing tank and add water to stir, add carbon powder binder while stirring, stop adding water when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com