Molybdenum disulfide nanoflowers supported zinc oxide quantum dots and its application in ammonia synthesis electrocatalyst

A technology of molybdenum disulfide and nanoflowers, which is applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of poor inherent conductivity and restricted catalytic activity, and achieve the effects of improving catalytic activity, increasing electron transfer rate, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

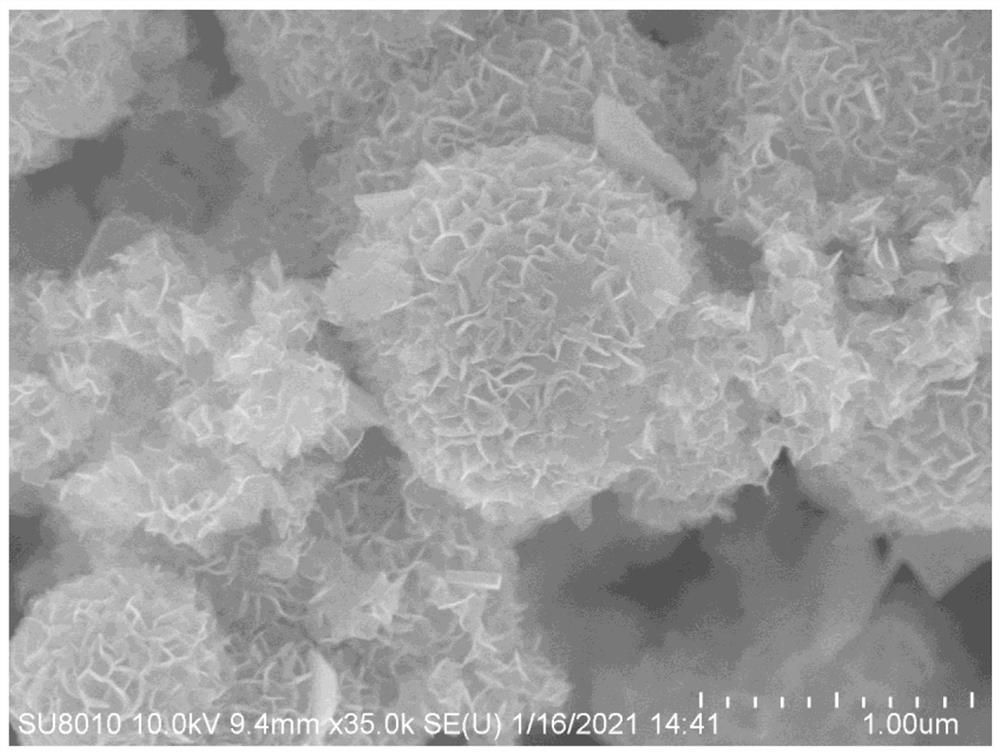

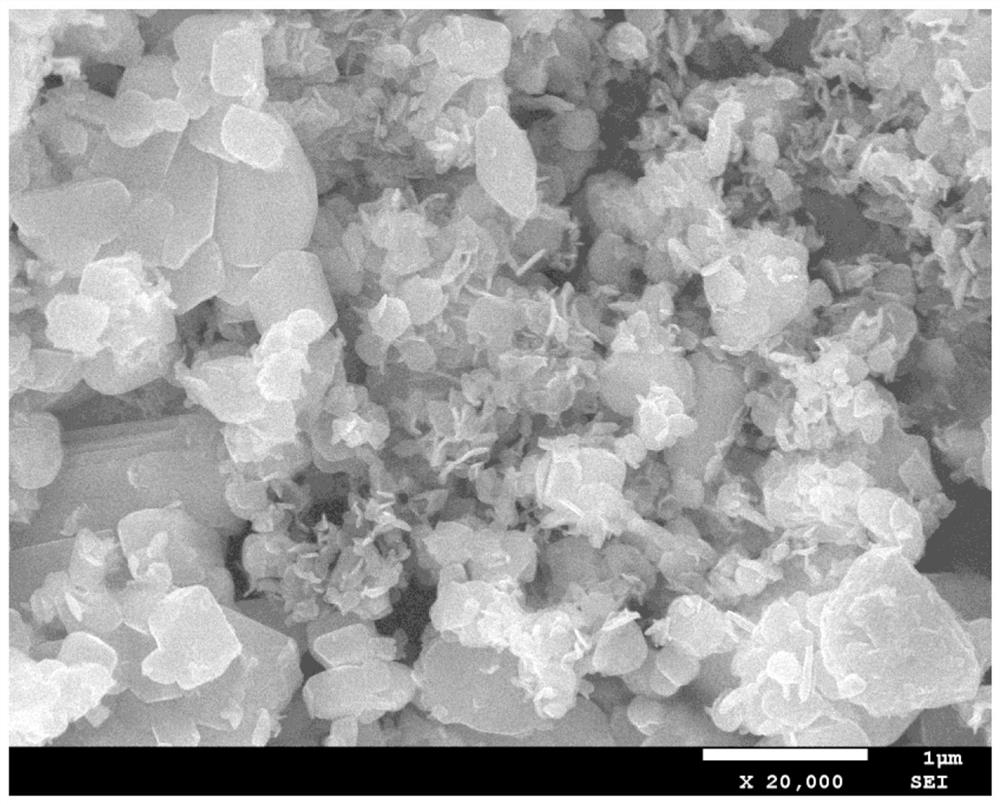

[0023] Add 1.24g of ammonium molybdate into 50mL of deionized water to dissolve to form a transparent solution, then add 2.28g of thiourea into it, stir to dissolve, then add 1ml of 3mol / L hydrochloric acid solution, stir for half an hour and ultrasonically disperse evenly, and finally the obtained The liquid was added to a 50ml reaction kettle with a polytetrafluoroethylene liner, hydrothermally reacted at 200°C for 24h, washed by centrifugation and dried in a vacuum oven. The sample is molybdenum disulfide nanoflowers, (see attached figure 1 ). Take 0.3g sample molybdenum disulfide nanoflowers and add it to 50ml of dehydrated ethanol containing 2.36g of zinc acetate and ice bath for 1 hour, stir while ice bathing, then add 35ml of dehydrated ethanol solution with 1gKOH to the above obtained solution dropwise. In the solution, stir for two hours while adding it dropwise, then let it stand for one hour, and finally keep it warm at 80°C for one hour. After centrifugal vacuum ...

Embodiment 2

[0025] Add 1.24g of ammonium molybdate into 30mL of deionized water to dissolve to form a transparent solution, then add 2.28g of thiourea into it, stir to dissolve, add 1ml of 3mol / L hydrochloric acid solution to it, stir for half an hour and ultrasonically disperse evenly, and finally the obtained The liquid was added to a 50ml reaction kettle with a polytetrafluoroethylene liner, hydrothermally reacted at 160°C for 18h, washed by centrifugation and dried in a vacuum oven. The sample is molybdenum disulfide nanoflowers. Take 0.3g sample of molybdenum disulfide nanoflowers and add it to 50ml of dehydrated ethanol containing 1g of zinc acetate and ice bath for 1 hour, stir while ice bathing, then add 50ml of dehydrated ethanol solution with 0.1g KOH dissolved in the above In the obtained solution, stir for two hours while adding it dropwise, then let it stand for one hour, and finally keep it warm at 80° C. for one hour, and dry it in a centrifugal vacuum. The sample is an amm...

Embodiment 3

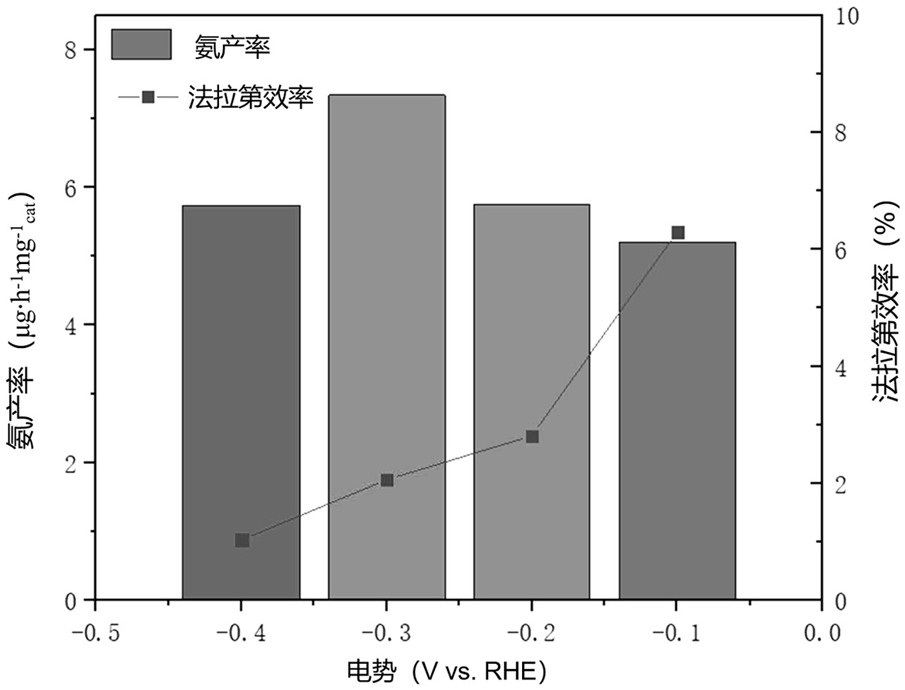

[0027] Add 1.24g ammonium molybdate to 40mL deionized water to dissolve to form a transparent solution, then add 2.28g thiourea to it, stir to dissolve, add 10ml 3mol / L hydrochloric acid solution to it, stir for half an hour and ultrasonically disperse evenly, and finally the obtained The liquid was added to a 50ml reaction kettle with a polytetrafluoroethylene liner, hydrothermally reacted at 170°C for 20h, washed by centrifugation and dried in a vacuum oven. The sample is molybdenum disulfide nanoflowers, synthetic ammonia yield and Faradaic efficiency (see attached Figure 7 )From Figure 7 It can be seen that the overall efficiency is the best at -0.1V. At this time, the faradaic efficiency of electrochemical synthesis of ammonia is 3.34%, and the ammonia yield is 3.06 μg h -1 ·mg -1 cat . Take 0.3g sample of molybdenum disulfide nanoflowers and add it to 50ml of dehydrated ethanol containing 1g of zinc acetate and ice bath for 1 hour, stir while ice bathing, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com