A method for removing impurities in acetonitrile prepared by ammoniation of acetic acid

A technology for ammoniation of acetic acid and acetonitrile, applied in the purification/separation of carboxylic acid nitrile, organic chemistry, etc., can solve the problems of high energy consumption, time and labor costs, long material cycle, long process flow, etc., and achieve low cost and high energy efficiency. Reduced consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

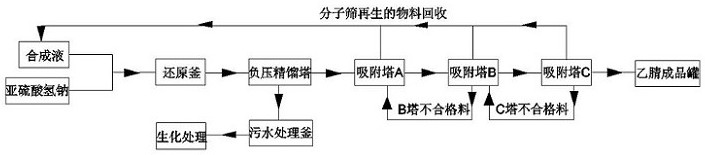

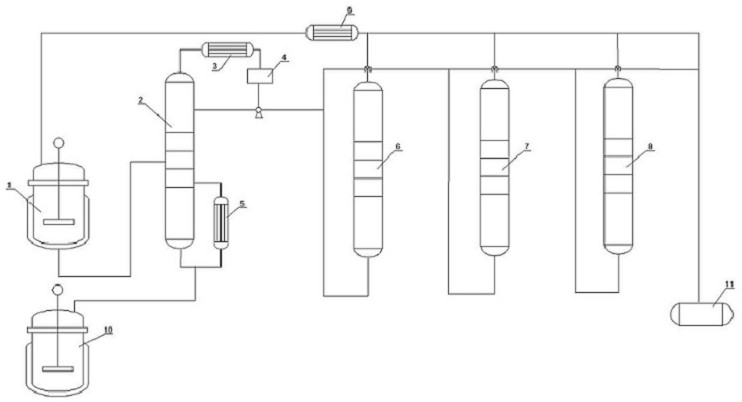

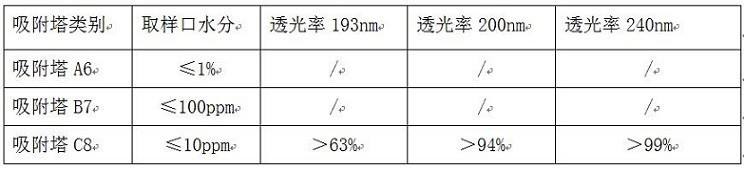

[0047] A method for removing impurities in acetonitrile prepared by ammoniation of acetic acid, comprising: reduction treatment, rectification, sewage decomposition treatment, molecular sieve multi-stage adsorption, and molecular sieve regeneration.

[0048] For the reduction treatment, the acetonitrile synthesis liquid prepared by the acetic acid ammonification method enters the reduction reaction kettle 1, then puts 0.1%wt sodium bisulfite into it, and starts the circulating water of the condenser connected to the reaction kettle (the temperature of the circulating water is 30°C), Turn on the reaction kettle to stir, feed steam into the coil of the reaction kettle to raise the temperature of the reduction reaction kettle 1 to 50°C, keep the temperature for 2 hours, and complete the reduction treatment until the acetone content in the acetonitrile synthesis liquid is less than or equal to 0.001%; open the reduction reaction kettle 1 and put Material valve, after the material...

Embodiment 2

[0078] A method for removing impurities in acetonitrile prepared by ammoniation of acetic acid, comprising: reduction treatment, rectification, sewage decomposition treatment, molecular sieve multi-stage adsorption, and molecular sieve regeneration.

[0079] For the reduction treatment, the acetonitrile synthesis liquid prepared by the acetic acid ammonification method enters the reduction reaction kettle 1, and then puts 0.3%wt sodium bisulfite into it, and turns on the circulating water of the condenser connected to the reaction kettle (the temperature of the circulating water is 35°C), Turn on the reaction kettle to stir, feed steam into the reaction kettle coil to raise the temperature of the reduction reaction kettle 1 to 70°C, and keep it warm for 2 hours until the acetone content in the acetonitrile synthesis liquid is less than or equal to 0.001%, and the reduction treatment is completed; open the reduction reaction kettle 1 and put Material valve, after the material en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com