Nano container filler with multiple self-repairing and anti-corrosion functions and application of nano container filler

A nano-container and self-healing technology, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of low proportion of active substances, difficult to meet, and low load, so as to enhance compatibility and delay corrosion The process, the effect of enhancing the barrier performance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

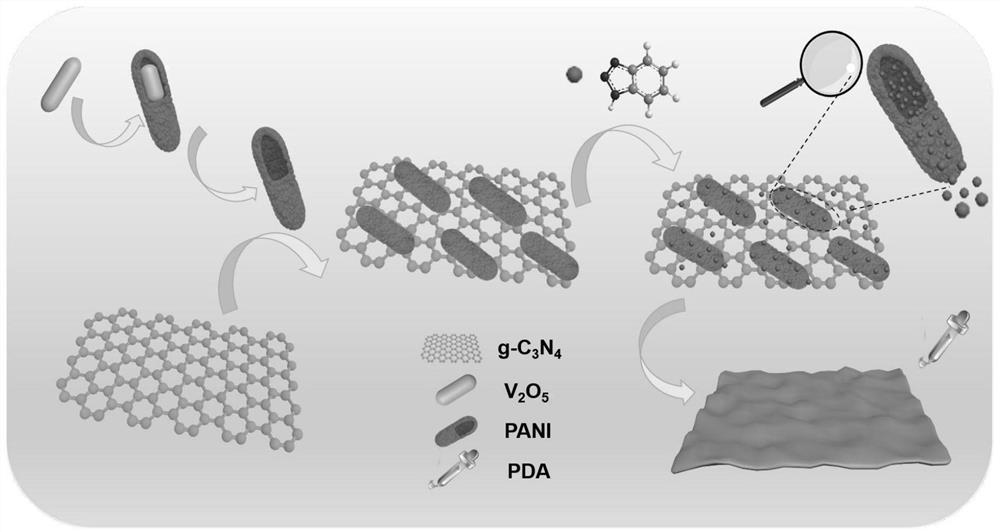

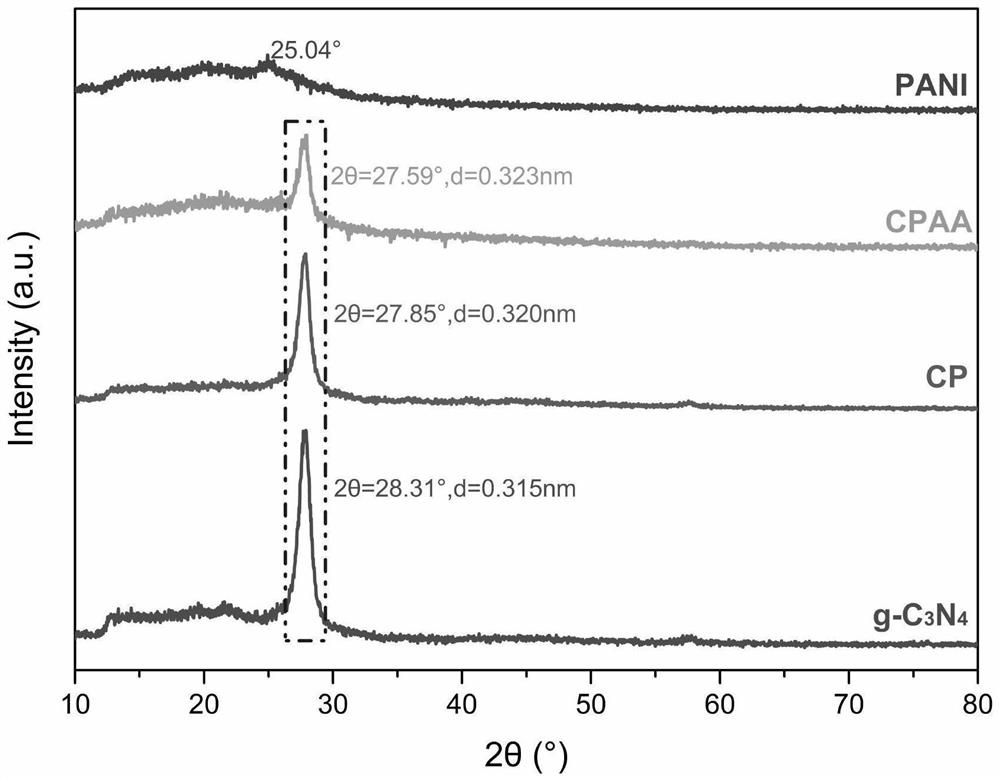

[0039] A preparation method of nano-container filler CPAA with multiple self-repairing and anti-corrosion functions, the flow chart is shown in figure 1 , the specific method steps are as follows:

[0040] Step 1, preparing hollow polyaniline capsules, the specific operations are as follows:

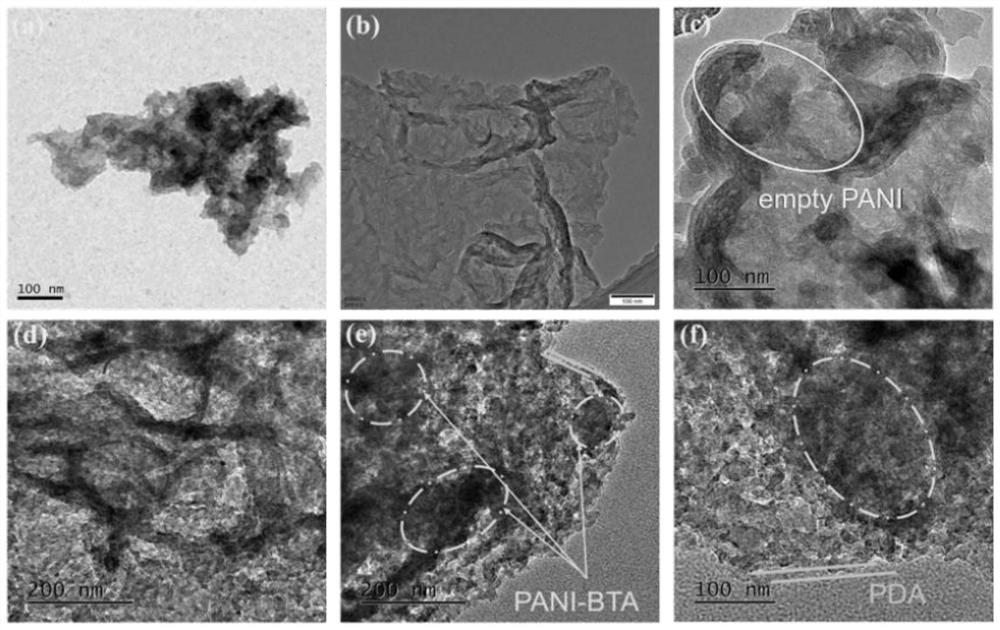

[0041] (1) Weigh 1.0g of V 2 o 5 Nanoparticles were added to 100mL deionized water, sonicated for 0.5 hours to make V 2 o 5 The nanoparticles were uniformly dispersed to form Suspension A.

[0042] (2) Add 1.0 mL of aniline monomer and 1.0 mL of concentrated sulfuric acid dropwise to the suspension A successively, stir and mix rapidly in an ice bath, and stir for 30 minutes to obtain the suspension B.

[0043] (3) Add an oxidizing agent (ammonium persulfate) to the suspension B, and continue the reaction at a temperature below 5°C for 3 hours; filter the product and wash it repeatedly with deionized water and ethanol, and obtain V after drying for 2 days 2 o 5 @PANI (VP) Composite. ...

Embodiment 2

[0051] An application method of nano-container filler CPAA with multiple self-repairing anticorrosion functions, the steps are as follows:

[0052] (1) Preparation of base material

[0053] Weigh 20g of water-based epoxy resin (WEP) and 10g of amine curing agent (WTF) purchased in the market respectively, mix them at room temperature, and obtain a uniformly dispersed base material after fully stirring (stirring at 600r / min for 15min). The main component of the curing agent is ethylenediamine (EDA), diethylenetriamine (DTA) or triethylenetetramine (TTA).

[0054] (2) Preparation of CPAA / waterborne epoxy self-healing composite coating

[0055] Weigh an appropriate amount of base material and the nano-container filler CPAA prepared in Example 1, mix and fully stir for 30 minutes under an electric stirrer to form a uniformly dispersed CPAA / WEPs composite coating.

[0056] (3) Preparation of coating

[0057] The composite paint is moved into the spray gun, and the paint is evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com