Silicon modified graphene water-based paint and preparation method thereof

A silicon-modified, alkene-based technology, applied in anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of insufficient anti-graffiti penetration and anti-graffiti lasting performance, limited film-forming resin types, and low anti-corrosion performance. , to achieve the effect of excellent anti-graffiti penetration performance, low cost and improved anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

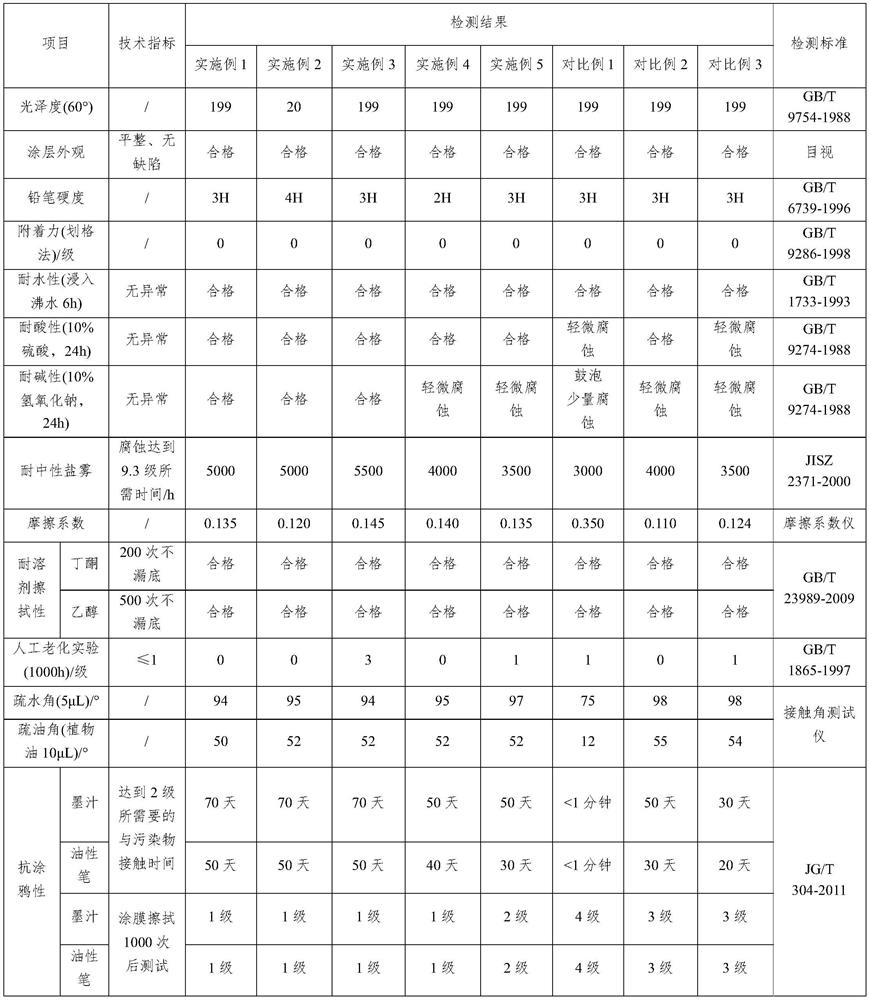

Examples

Embodiment 1

[0055] This embodiment is used to illustrate silicon-modified graphene water-based paint disclosed by the present invention and preparation method thereof, comprising the following steps:

[0056] (1) Weigh the raw materials of the following components according to the mass ratio

[0057] 35 parts of epoxy-modified water-based acrylic resin, 10 parts of water-based polyurethane resin, 0.8 parts of dimethylethanolamine, 1.5 parts of propylene glycol methyl ether acetate, 1.5 parts of ethylene glycol monobutyl ether, 10 parts of silicon-modified graphene slurry, 10.8 parts of partially methylated melamine formaldehyde resin, 0.9 parts of dinonyl naphthalene disulfonic acid, 2 parts of adhesion promoter, 0.5 parts of defoamer togo8050, 1.5 parts of water-based color essence, 25.5 parts of deionized water;

[0058] The preparation of the silicon-modified graphene slurry:

[0059] The first step: ultrasonically disperse 10 parts of graphene oxide in 40 parts of deionized water and...

Embodiment 2

[0063] This embodiment is used to illustrate silicon-modified graphene water-based paint disclosed by the present invention and preparation method thereof, comprising the following steps:

[0064] (1) Weigh the raw materials of the following components according to the mass ratio

[0065] 35 parts of epoxy-modified water-based acrylic resin, 10 parts of water-based polyurethane resin, 0.8 parts of dimethylethanolamine, 1.5 parts of propylene glycol methyl ether acetate, 1.5 parts of ethylene glycol monobutyl ether, 10 parts of silicon-modified graphene slurry, 10.8 parts of partially methylated melamine formaldehyde resin, 0.9 parts of dinonyl naphthalene disulfonic acid, 2 parts of adhesion promoter, 0.5 parts of defoamer togo8050, 1.5 parts of water-based color essence, 1.5 parts of matte powder, 24 parts of deionized water ;

[0066] The preparation of the silicon-modified graphene slurry:

[0067] The first step: ultrasonically disperse 10 parts of graphene oxide in 40 p...

Embodiment 3

[0071] This embodiment is used to illustrate silicon-modified graphene water-based paint disclosed by the present invention and preparation method thereof, comprising the following steps:

[0072] (1) Weigh the raw materials of the following components according to the mass ratio

[0073] 50 parts of water-based epoxy resin, 1 part of triethanolamine, 1 part of propylene glycol methyl ether, 2 parts of isopropanol, 10 parts of silicon-modified graphene slurry, 2 parts of phenolic resin, 3.5 parts of partially methylated melamine formaldehyde resin, 0.5 parts of toluenesulfonic acid, 0.5 parts of dinonylnaphthalenesulfonic acid, 2 parts of adhesion promoter, 0.3 parts of defoamer togo8050, 1.5 parts of water-based color essence, 25.7 parts of deionized water;

[0074] The preparation of the silicon-modified graphene slurry:

[0075] The first step: ultrasonically disperse 10 parts of graphene oxide in 30 parts of deionized water and 30 parts of ethanol, then put it into a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com