Method for preparing nano-silver with different particle sizes by using surfactant

A surfactant and nano-silver technology, applied in the direction of nano-technology, can solve the problems of excessive particle size of nano-silver particles, harsh operating conditions, poor antibacterial performance, etc., and achieve widening of application fields, low cost, and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

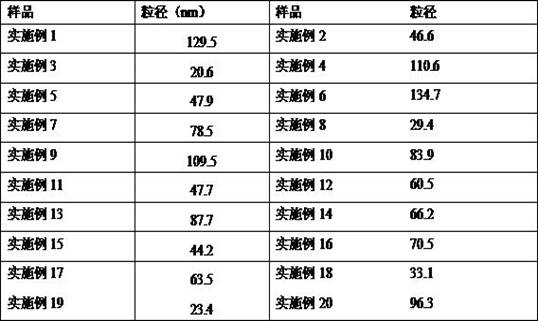

Examples

Embodiment 1

[0018] Prepare a silver nitrate solution with a concentration of 0.1g / L, slowly drop the surfactant solution into the silver nitrate solution within 30min to obtain a solution; dissolve sufficient tannic acid and surfactant in water to obtain b solution, b The concentration of surfactant in the solution is the same as that of solution a, slowly drop solution b into solution a within 60 minutes to prepare solution c; cool solution c to room temperature, adjust the pH value to 5.0 with 0.01mol / L hydrochloric acid, and complete Preparation of silver nanoparticles. Among them, the reaction temperature during the preparation of solution a and solution c is 20°C, the concentration of surfactant in solution a and solution b is 0.7mmol / L, the stirring speed is 300rpm, and the surfactant is 0.593mmol / L CMC and 7.9 HLB Nonionic surfactant.

Embodiment 2

[0020] Prepare a silver nitrate solution with a concentration of 2g / L, and slowly drop the surfactant solution into the silver nitrate solution within 60 minutes to obtain a solution; a sufficient amount of ascorbic acid and surfactant are dissolved in water to obtain a b solution. The concentration of the active agent is the same as that of solution a, slowly drop solution b into solution a within 150 minutes to obtain solution c; cool solution c to room temperature, adjust the pH value to 3.0 with 0.01mol / L hydrochloric acid, and complete the preparation of nano silver preparation. Among them, the reaction temperature during the preparation of solution a and solution c is 50°C, the concentration of surfactant in solution a and solution b is 1.0mmol / L, the stirring speed is 500rpm, and the surfactant is 0.593mmol / L CMC and 7.9 HLB Nonionic surfactant.

Embodiment 3

[0022] Prepare a silver nitrate solution with a concentration of 0.15g / L, and slowly drop the surfactant solution into the silver nitrate solution within 60 minutes to obtain a solution; a sufficient amount of sodium borohydride and surfactant are dissolved in water to obtain a b solution, b The concentration of surfactant in the solution is the same as that of solution a, slowly drop solution b into solution a within 90 minutes to obtain solution c; cool solution c to room temperature, adjust the pH value to 6.0 with 0.01mol / L hydrochloric acid, and complete Preparation of silver nanoparticles. Among them, the reaction temperature during the preparation of solution a and solution c is 40°C, the concentration of surfactant in solution a and solution b is 1.3mmol / L, the stirring speed is 600rpm, and the surfactant is 0.593mmol / L CMC and 7.9 HLB Nonionic surfactant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com