WO3/SiO2 composite film prepared based on sol-gel method as well as preparation method and application thereof

A technology of sol-gel method and composite thin film, which is applied in the direction of coating, etc., can solve the problem of few fields of electrochromism, and achieve the effects of short response time, large light modulation range, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

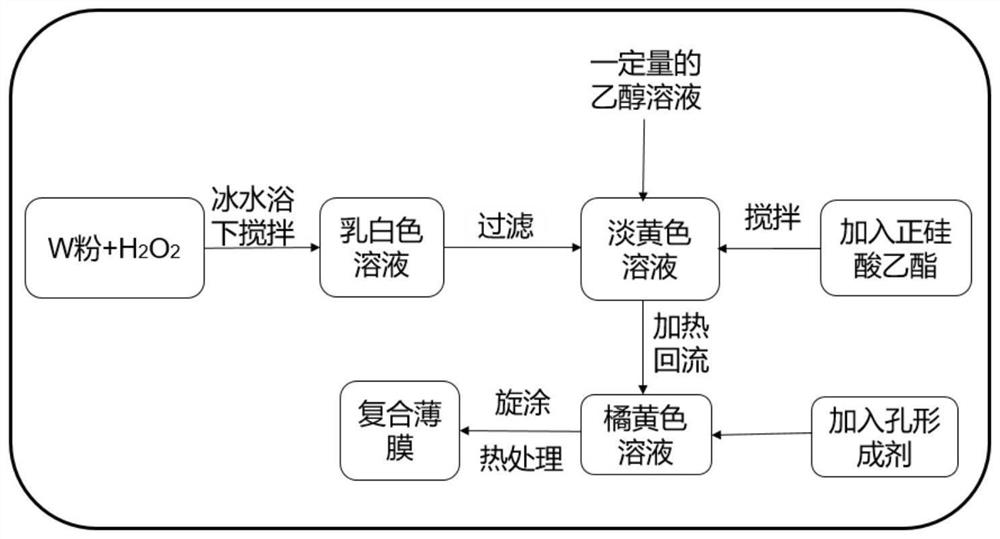

[0025] Further, a kind of WO prepared based on sol-gel method 3 / SiO 2 The preparation method of composite film, concrete operation steps are as follows:

[0026] (2.1), add an appropriate amount of tungsten powder into a three-necked flask, take an appropriate amount of hydrogen peroxide and add it into the three-necked flask through a burette, stir with a magnetic stirrer until the tungsten powder is completely dissolved, and then filter to obtain clarified WO 3 Precursor solution;

[0027] (2.2), the WO to be obtained 3 Put the precursor solution into a three-necked flask, add an appropriate amount of ethyl orthosilicate, stir for a period of time, then add an appropriate amount of ethanol, reflux at 45°C for a period of time, raise the temperature to 80°C, and then add an appropriate amount of pore forming agent, After stirring for a while to get WO 3 sol, will result in WO 3 The sol was cooled to room temperature for use;

[0028] (2.3), the WO to be obtained 3 The...

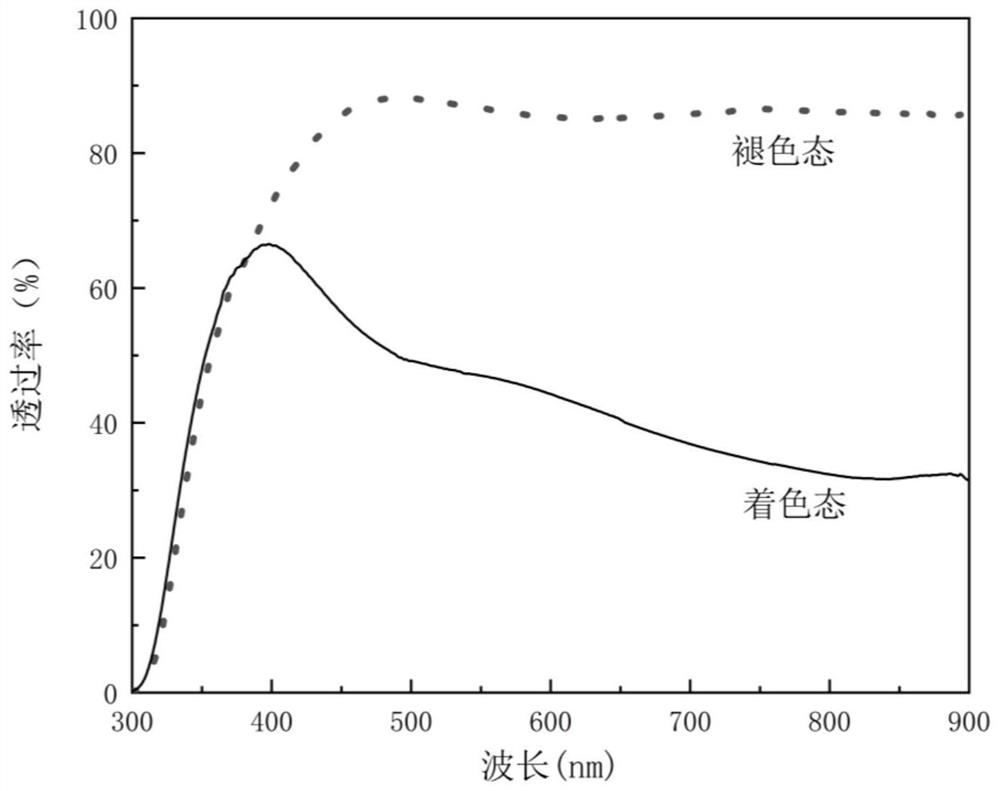

Embodiment 1

[0038] 1) Weigh 2.5g of tungsten powder at room temperature and place it in a three-necked flask equipped with a constant burette, place the three-necked flask in a water bath filled with ice cubes, use a graduated cylinder to measure 10ml of hydrogen peroxide and place it in a constant burette , add dropwise at a rate of 4 seconds, and stir magnetically for 6 hours. After the tungsten powder completely reacts with hydrogen peroxide, a milky white solution is obtained. Transfer the solution to a vacuum filter funnel, and filter to obtain a clear solution;

[0039] 2), transfer the obtained clear solution to another 150ml three-necked flask equipped with a stirrer, a condenser and a thermometer, weigh 0.5664g ethyl orthosilicate with a measuring cylinder, pour it into a three-necked flask, and stir magnetically for 1h to obtain Precursor solution of the composite film; use a graduated cylinder to measure 15ml of ethanol solution and pour it into a three-necked flask, heat to ref...

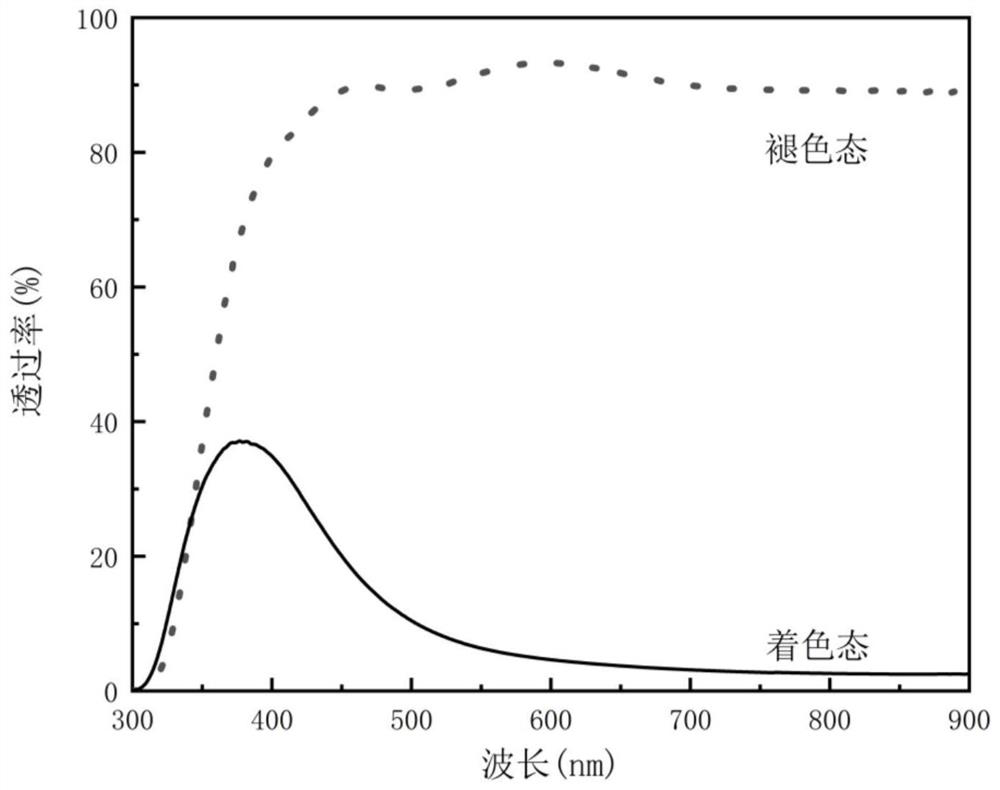

Embodiment 2

[0042] 1) Weigh 2.5g of tungsten powder at room temperature and place it in a three-necked flask equipped with a constant burette, place the three-necked flask in a water bath filled with ice cubes, use a graduated cylinder to measure 15ml of hydrogen peroxide and place it in a constant burette , add dropwise at a rate of 4 seconds, and stir magnetically for 6 hours. After the tungsten powder completely reacts with hydrogen peroxide, a milky white solution is obtained. Transfer the solution to a vacuum filter funnel, and filter to obtain a clear solution;

[0043] 2), transfer the obtained clear solution to another 150ml three-necked flask equipped with a stirrer, a condenser and a thermometer, weigh 0.8496g tetraethyl orthosilicate with a measuring cylinder, pour it into a three-necked flask, and stir magnetically for 1h to obtain Precursor solution of the composite film; use a measuring cylinder to measure 15ml of ethanol solution into a three-necked flask, heat to reflux, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com