A kind of high strength and toughness magnesium alloy and preparation method thereof

A magnesium alloy, high-strength technology, applied in the field of magnesium alloys, can solve the problems of mismatch of strength and plasticity, description of mechanical properties of heat treatment process, less than 10%, etc., and achieve the effects of improved strength and toughness, small size, and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

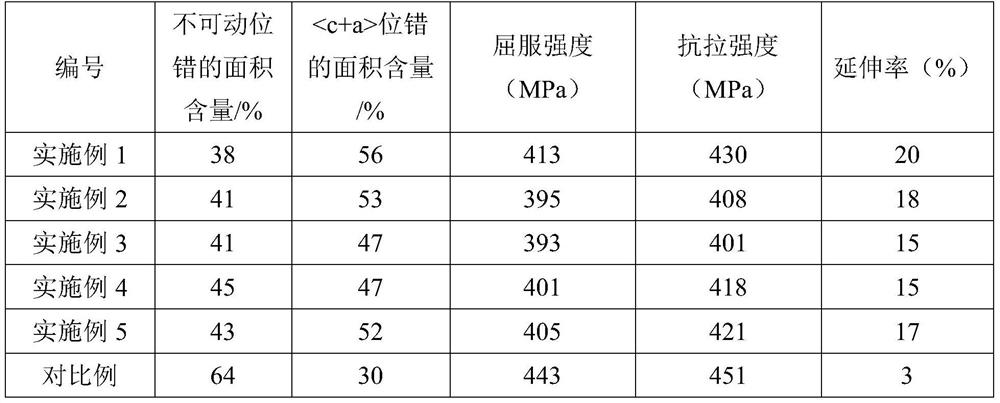

[0031] The mass percentage composition of the high-strength and tough magnesium alloy in this embodiment is: Sm: 2.0%, Mn: 0.8%, Ca: 0.6%, Zn: 0.5%, and the balance is Mg and inevitable impurities.

[0032] The preparation of the high-strength and tough magnesium alloy of the present embodiment includes the following steps:

[0033] 1) Preparation of magnesium alloy cast rods:

[0034] a) According to the alloy composition of the magnesium alloy, calculate the respective weights of the required Mg ingots, Zn ingots, Mg-25Sm master alloys, Mg-10Mn master alloys, and Mg-25Ca master alloys, prepare the materials, and dry them at 300°C. time 1.5h;

[0035] b) in SF 6 +CO 2 Under gas protection, put the dried pure Mg ingot into a crucible that has been preheated to 550°C, and the furnace temperature rises to 730°C until Mg is completely melted;

[0036] c) at 730°C, add the dried pure Zn ingot and Mg-10Mn master alloy into the magnesium melt, and fully stir until melting;

[0...

Embodiment 2

[0045] The difference between Example 2 and Example 1 is that the casting speed of the semi-continuous ingot is 150mm / min, the cooling water flow rate is 90L / min, and the peeled cast rod and extrusion die are preheated in a resistance furnace at 270°C for 1.5h , the extruder is preheated to 270 ° C, the extrusion ratio is 16:1, and the extrusion deformed magnesium alloy extruded bar is annealed at 300 ° C for 15 minutes.

Embodiment 3

[0047] The difference between this example and Example 1 is that the mass percentage composition of the magnesium alloy is Sm: 1.7%, Mn: 0.8%, Ca: 0.5%, Zn: 0.5%, and the balance is Mg and inevitable impurities. After peeling The cast bar and extrusion die were preheated in a resistance furnace at 270°C for 2h, the extrusion speed was 1mm / s, and the extruded magnesium alloy extruded bar was annealed at 350°C for 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com