Dismounting and replacing construction method for inverted arch of floor heave section of high-speed rail tunnel.

A construction method and tunnel technology, which is applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of short disease control period, low construction efficiency, long construction time, etc., and achieve improved mechanical and manual work efficiency and low labor intensity , The effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

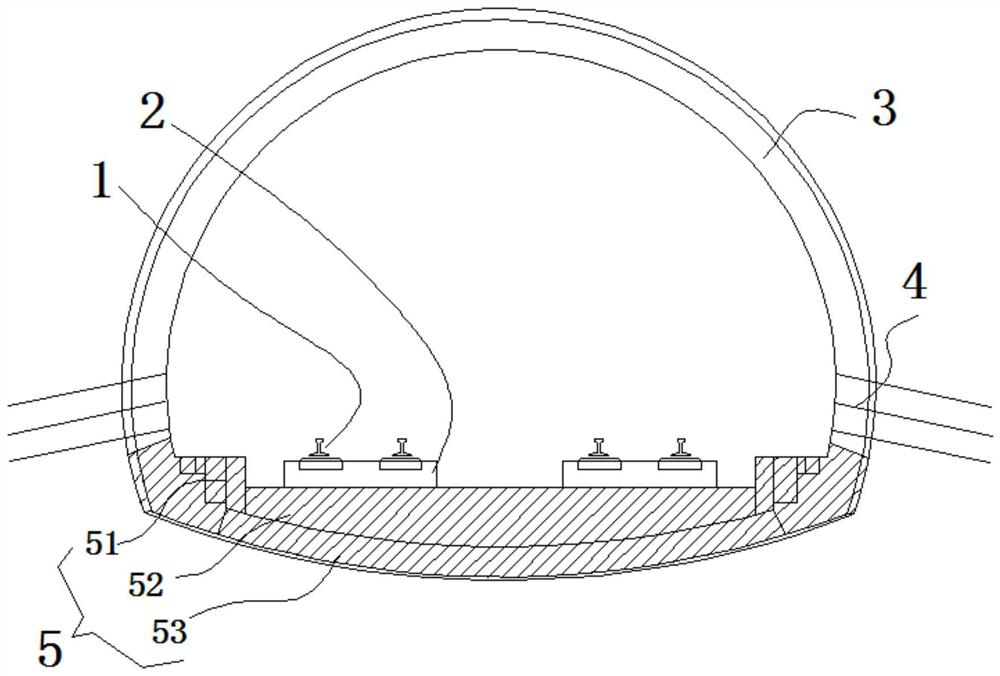

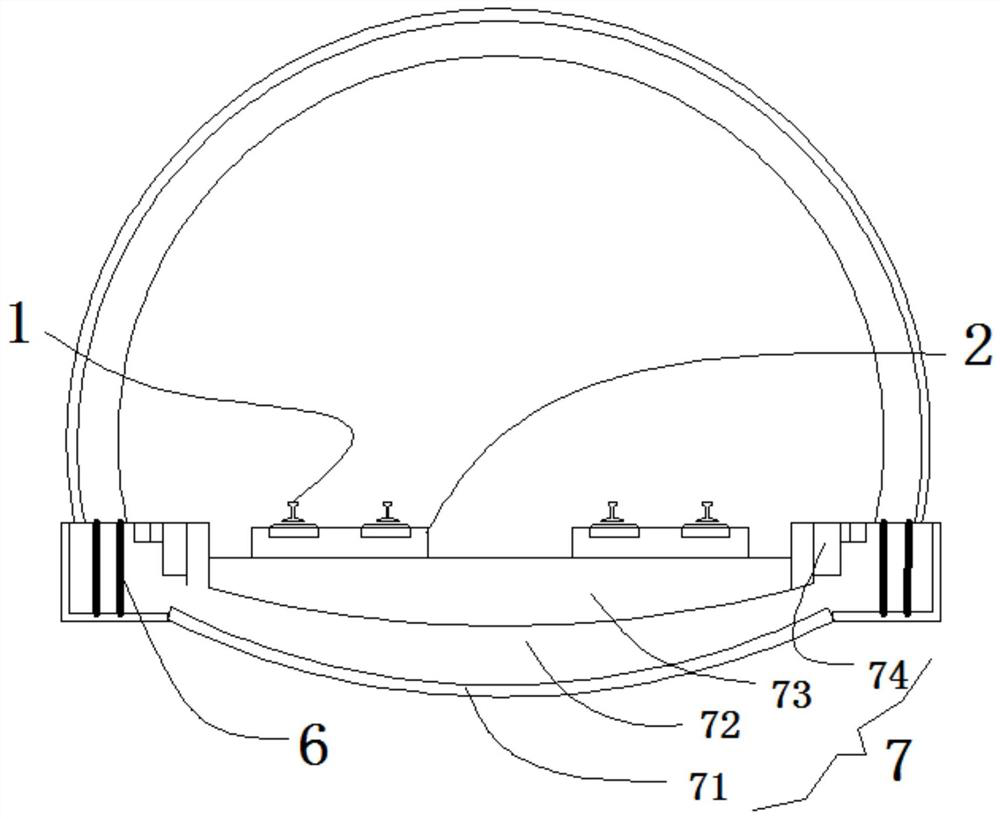

[0032] The technical solutions in the embodiments of the present invention will be described below, apparent, as described herein is merely embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

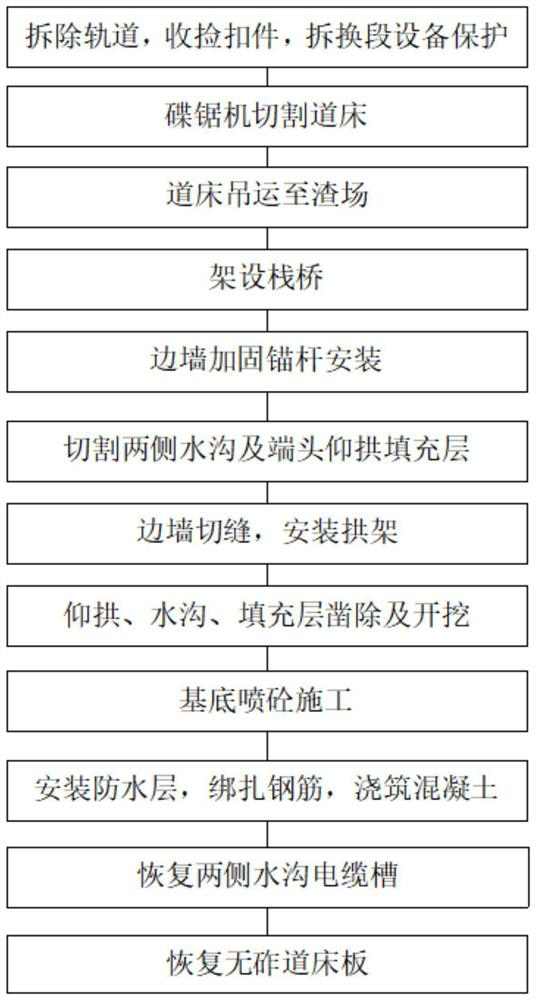

[0033] A method for removing the tuning of the high-speed rail tunnel section, including the following steps:

[0034] S1, demolition track 1, collected fasteners, and replacement segment equipment protection;

[0035] S2, disc saw machine cutting road 2;

[0036] S3, the bed lifting to the slag field: excavator lifting the cutting road 2 into the flat trail, clearing the tunnel to the tunnel; 40 minutes per cut, each of the concrete weights of about 5 tons.

[0037] S4, set a stack bridge 9: Shang Diagene Housing Take the Stack Bridge 9;

[0038] S5, side wall reinforcing anchor 4 installation;

[0039] S6, cutting the two-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com