Efficient electric combustion furnace for collecting fire coal PM2.5

A PM2.5, electric furnace technology, applied in the combustion of solid fuel, air/fuel supply for combustion, combustion method, etc., can solve problems such as affecting combustion state, insufficient air supply, affecting detection results, etc., to reduce Pollution, the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

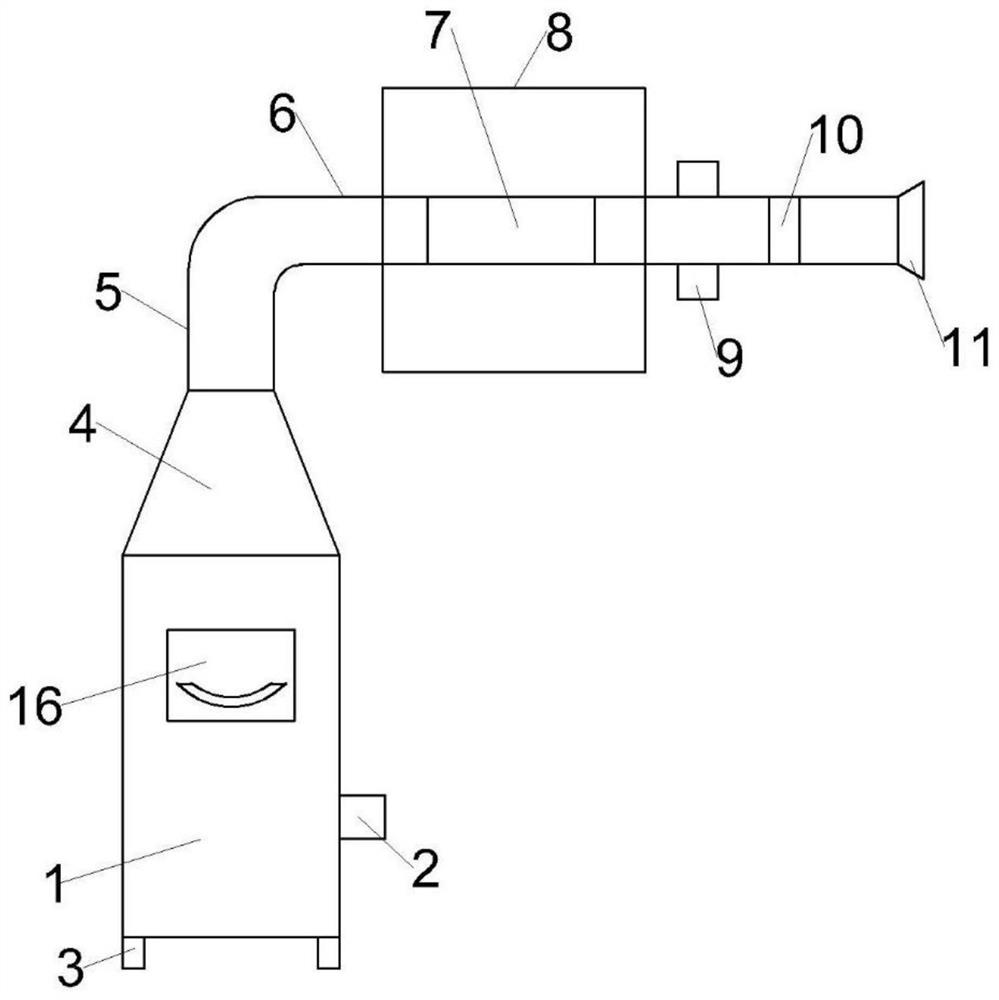

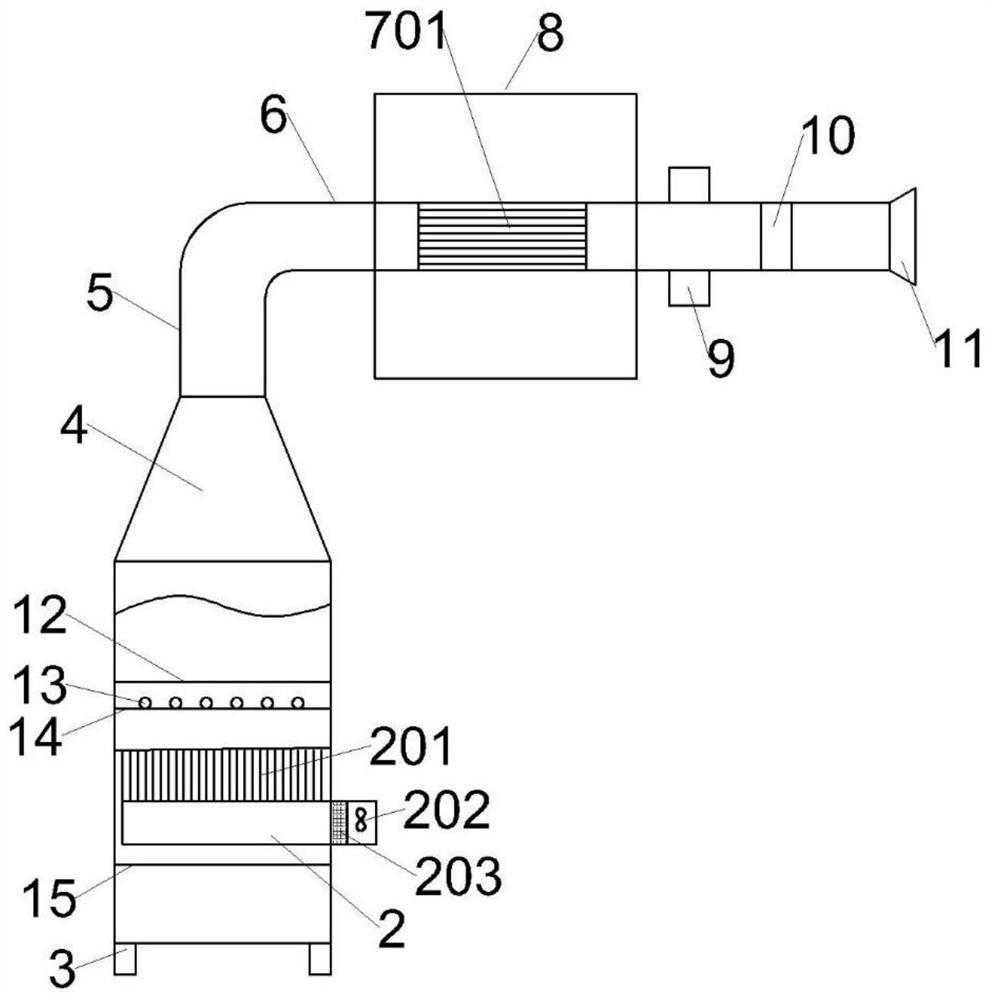

[0035] refer to Figure 1-4 As shown in the figure, this embodiment provides a high-efficiency electric combustion furnace for collecting coal-fired PM2.5, including a furnace body 1, the top of the furnace body 1 is connected with a flow velocity acceleration channel 4, and the top of the flow velocity acceleration channel 4 is connected with an exhaust pipe 6. The air pipe 6 is sequentially provided with a cooling pipe assembly 7, a PM2.5 detection end 9, and an exhaust filter element 10 along the air flow direction;

[0036] The furnace body 1 is fixedly connected with a heating wire 13, a support plate 14, an air inlet channel 2, and an anti-heating plate 15 sequentially from top to bottom. The side wall of the furnace body 1 is detachably connected with a feeding baffle 16, which is vertically fixed and connected. There is a material storage plate 12, the material storage plate 12 is a hollow structure, the material storage plate 12 is located above the heating wire 13, a...

Embodiment 2

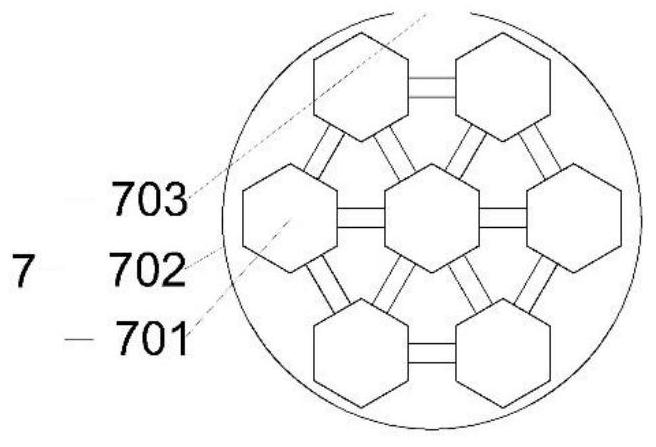

[0055] refer to Figure 5-6 As shown, the difference between the high-efficiency electric combustion furnace of this embodiment and the first embodiment is only that the inner wall of the exhaust pipe 6 is provided with a first reducing protrusion 601, and the inner wall of the shunt pipe 701 is provided with a plurality of second reducing protrusions 7011, The first variable diameter protrusion 601 divides the exhaust pipe 6 into two opposite conical truncated structures, and the second variable diameter protrusion 7011 divides the inner wall of the shunt pipe 701 into several conical truncated structures. According to the Laval structure principle, the airflow When passing through the first reducing protrusion 601 and the second reducing protrusion 7011, there will be a process of compression and expansion, which will increase the flow rate of the airflow through the exhaust pipe 6 and the shunt pipe 701, thereby enhancing the overall electrical The air intake and air circul...

Embodiment 3

[0057] refer to Figure 7 As shown, the difference between the high-efficiency electric combustion furnace of this embodiment and the first embodiment is only that the furnace body 1 and the flow velocity acceleration channel 4 are detachably connected, and the outer side wall of the furnace body 1 is fixedly connected with a first fixed block 101, and the flow velocity acceleration channel 4. A second fixing block 401 is fixedly connected to the outer side wall. The top of the second fixing block 401 is rotatably connected with a clamping wrench 402. The middle of the clamping wrench 402 is rotatably connected with a clamping buckle 403, and the clamping buckle 403 is away from the clamping wrench 402. One side is set in contact with the bottom of the second fixing block 401, and the flow velocity acceleration channel 4 is made of high temperature resistant transparent material, which is convenient for observing the combustion situation in the furnace body 1, and the flow velo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com