Lithium iron phosphate and its preparation method and application

A lithium iron phosphate and lithium source technology, applied in chemical instruments and methods, phosphorus compounds, nanotechnology for materials and surface science, etc., can solve the problem of impurity in sintering costs, uneven mixing of raw materials, loss of material properties, etc. problem, to achieve the effects of fast ammonia drop rate, guaranteed reaction rate, and increased nucleation number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

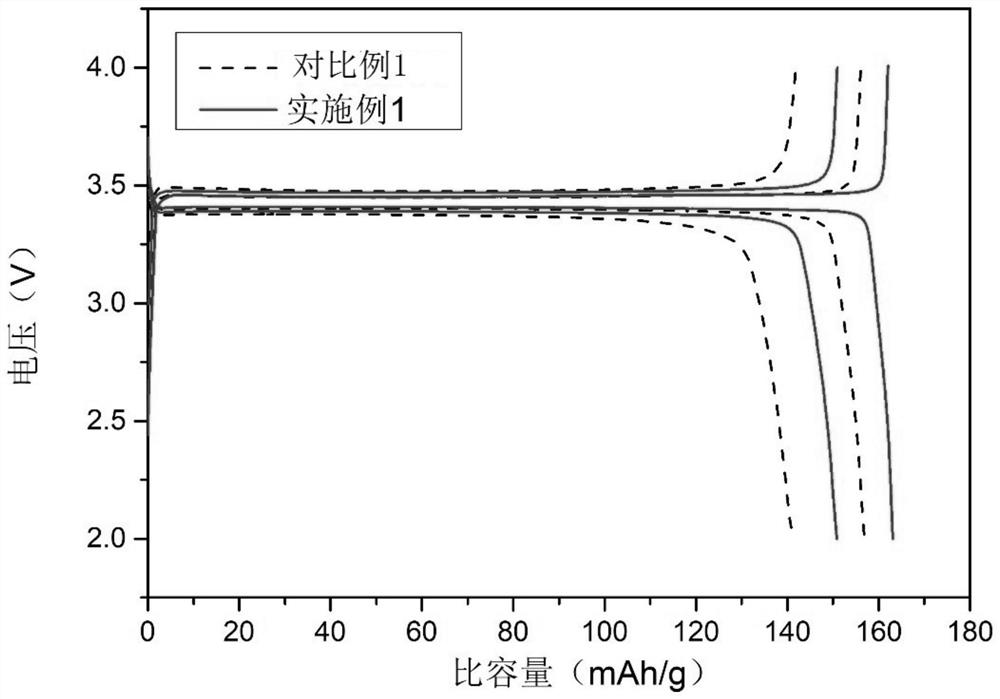

Examples

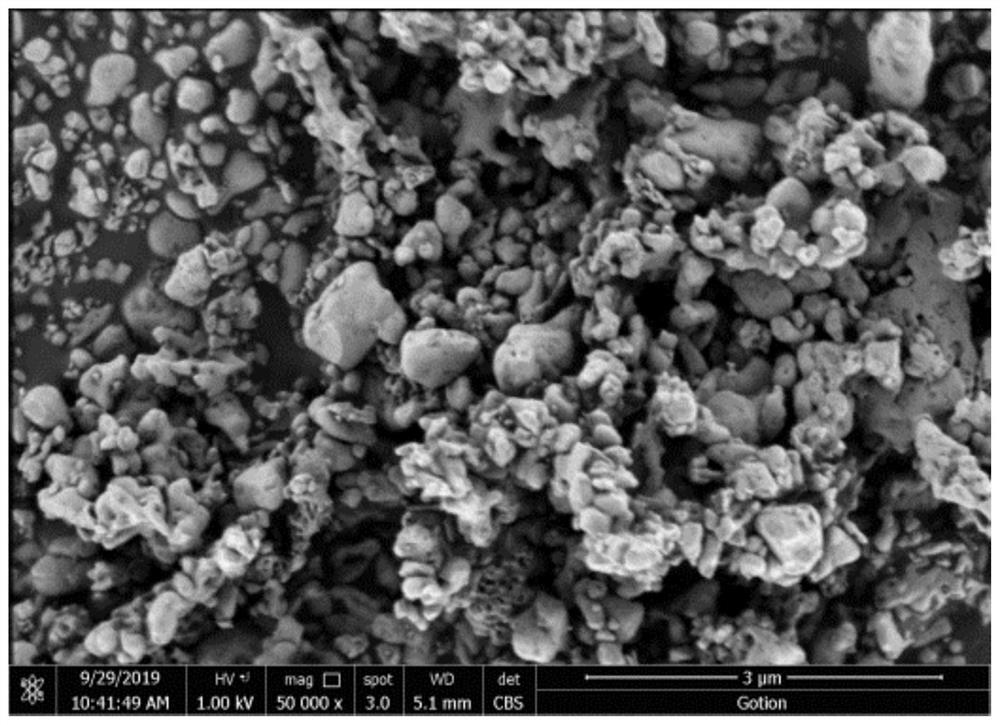

Embodiment 1

[0058] This embodiment provides a preparation method of lithium iron phosphate, the preparation method comprising:

[0059] 1, the particle diameter is added in the emulsifier solution that is formed by sodium lauryl sulfate and polyoxyethylene alkylphenol ether after vacuum-drying the nano lithium carbonate of 400nm, keeps stirring; Then add butyl acrylate and divinylbenzene ( The two are used as the first initiator), the free radical is used to initiate the first polymerization reaction, the temperature of the first polymerization reaction is 70° C., and the time is 4 hours to obtain the intermediate product A.

[0060] Wherein, the ratio of emulsifying agent and lithium carbonate mol ratio is 0.5:1; The mass ratio of sodium lauryl sulfate and polyoxyethylene alkylphenol ether is 1.5:1, and the mol ratio of divinylbenzene in the first initiator is 5%, the mol ratio of the first initiator and lithium carbonate is 0.5:1.

[0061] 2. Prepare a mixed solution of methyl methacry...

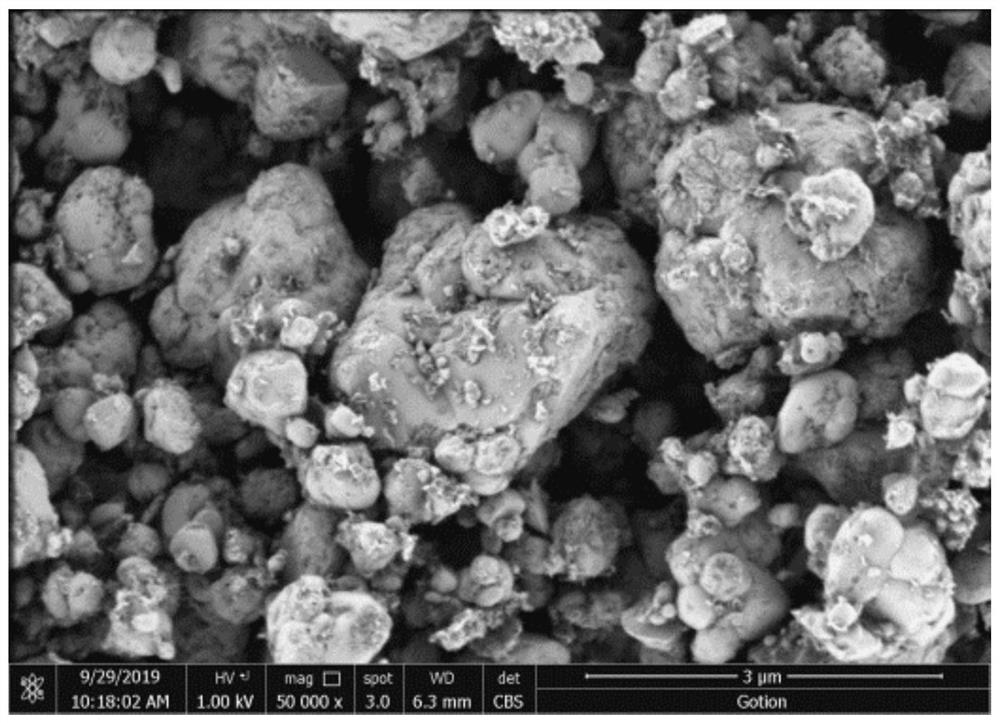

Embodiment 2

[0068] This embodiment provides a preparation method of lithium iron phosphate, the preparation method comprising:

[0069] 1, the particle diameter is added in the emulsifier solution that is formed by sodium lauryl sulfate and polyoxyethylene alkylphenol ether after vacuum-drying the nano lithium carbonate of 400nm, keeps stirring; Then add butyl acrylate and divinylbenzene ( The two are used as the first initiator), the free radical is used to initiate the first polymerization reaction, the temperature of the first polymerization reaction is 70° C., and the time is 4 hours to obtain the intermediate product A.

[0070] Wherein, the molar ratio of emulsifier to lithium carbonate is 0.5:1. The mass ratio of sodium lauryl sulfate and polyoxyethylene alkylphenol ether is 1.5:1, and the mol ratio of divinylbenzene in the first initiator is 5%, and the mol ratio of the first initiator and lithium carbonate is 0.6: 1.

[0071] 2. Prepare a mixed solution of methyl methacrylate, ...

Embodiment 3

[0078] This embodiment provides a preparation method of lithium iron phosphate, the preparation method comprising:

[0079] 1. After vacuum-drying the nano-lithium carbonate with a particle diameter of 300nm, add in the emulsifier solution formed by sodium lauryl sulfate and polyoxyethylene alkylphenol ether, keep stirring; then add butyl acrylate and divinylbenzene ( The two are used as the first initiator), and the free radical is used to initiate the first polymerization reaction. The temperature of the first polymerization reaction is 60° C. and the time is 2 hours, and the intermediate product A is obtained.

[0080] Wherein, the mol ratio of emulsifier and lithium carbonate is 0.5:1. The mass ratio of sodium lauryl sulfate and polyoxyethylene alkylphenol ether is 1:1, and the mol ratio of divinylbenzene in the first initiator is 5%, and the mol ratio of the first initiator and lithium carbonate is 0.6: 1.

[0081] 2. Prepare a mixed solution of methyl methacrylate, div...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com