Graphite particles modified by thiol modification and its preparation method and application

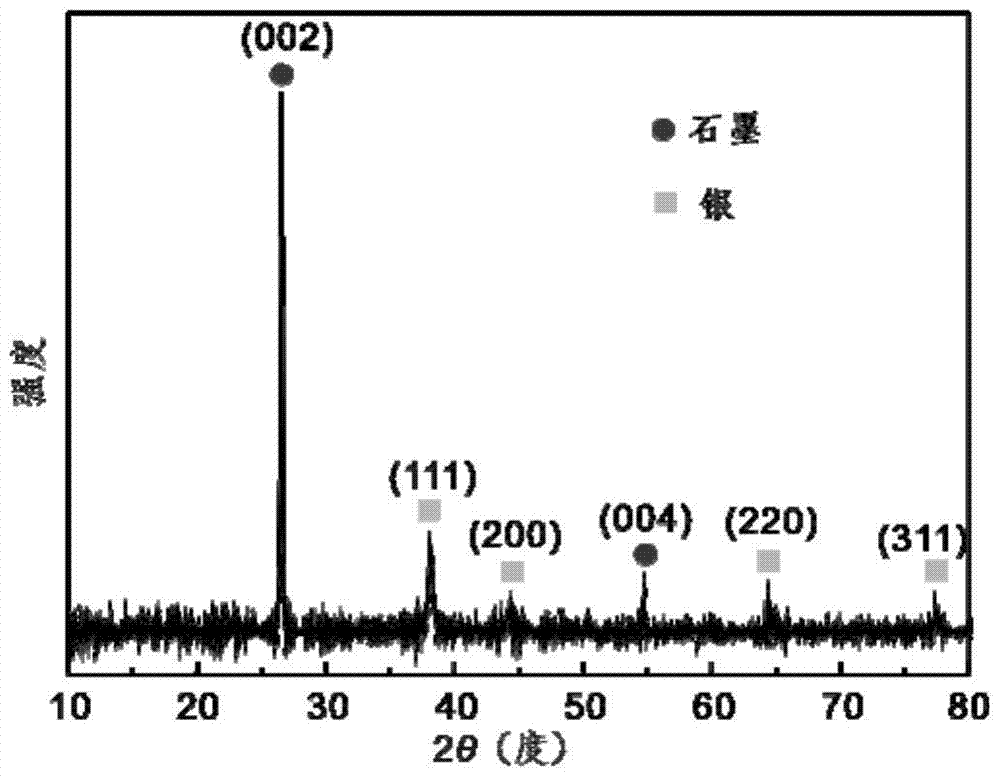

A technology of sulfhydrylation modification and graphite particles, which is applied in the directions of graphite and carbon-silicon compound conductors, can solve the problems of difficulty in preparing dense and thin silver-shell graphite particles, low surface reactivity of graphite particles, and difficult nucleation of silver nuclei. To achieve the effect of dense and continuous silver shell layer, easy to popularize and apply, and low silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Cleaning steps: Soxhlet extractor can effectively remove oil stains on the surface of graphite particles (such as: diesel oil, vegetable oil, etc.). Pour 100 mL of water / ethanol mixed solvent with a volume ratio of 1:1 into a Soxhlet extractor round bottom flask, then wrap 30 g of graphite particles with filter paper, place in the Soxhlet extractor, and reflux for 6 h. After that, wash with ethanol for 3 times, filter with suction, dry in an oven at 60°C for 2 hours, and set aside;

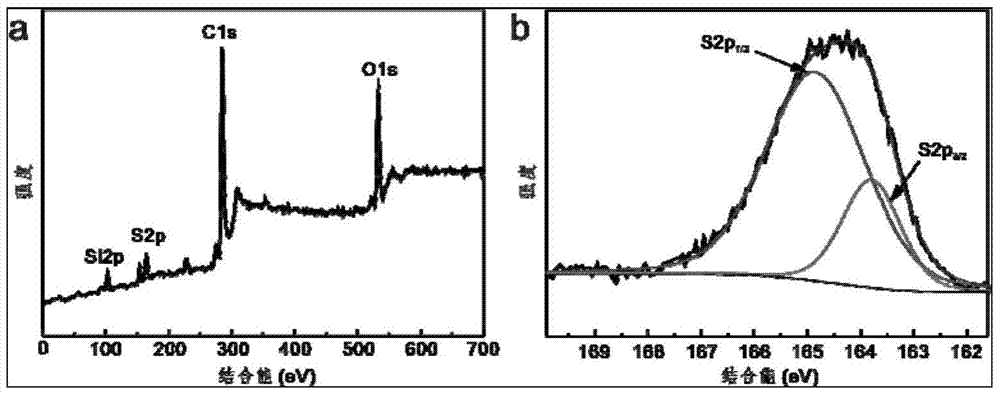

[0038] Mercaptolation modification: Weigh 2.5g of graphite particles and place them in a three-necked flask, pour 18mL of deionized water and 82mL of ethanol (volume ratio: 0.22:1) in sequence, stir magnetically, and when the temperature rises to 60°C, add γ- Mercapto-propyltrimethoxysilane and ammonia water, to ensure that the concentrations of the two are 5mL / L and 20mL / L, respectively, and react at this temperature for 6h, filter with suction, wash with absolute ethanol, repeat 3 times, ...

Embodiment 2

[0044] The cleaning of graphite particles and the liquid phase chemical reduction of silver are the same as in Example 1.

[0045] Thiolation modification: Weigh 2.5g of graphite and place it in a three-necked flask, pour 66mL of deionized water and 33mL of ethanol (volume ratio: 2:1) in sequence, stir magnetically, and when the temperature rises to 85°C, add γ-mercapto -Propyltrimethoxysilane and ammonia water, ensure that the concentrations of the two are 10mL / L and 200mL / L respectively, and react at this temperature for 6h, filter with suction, wash with absolute ethanol, repeat 3 times, and store at 60°C Dry in an oven for 6 hours.

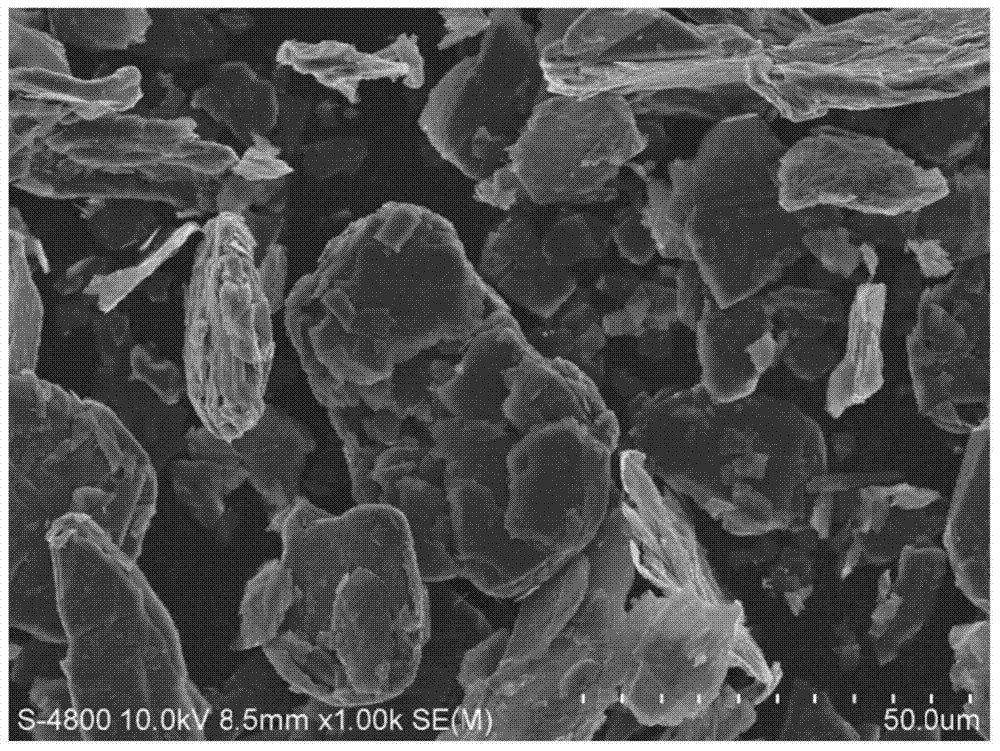

[0046] Such as Figure 6 As shown, it can be seen that the surface morphology of the graphite@Ag composite particles synthesized in Example 2 of the present invention is consistent with the effect of Example 1.

Embodiment 3

[0048] The cleaning of graphite particles and the liquid phase chemical reduction of silver are the same as in Example 1.

[0049] Thiolation modification: Weigh 2.5g of graphite and place it in a three-necked flask, pour 2mL of deionized water and 100mL of ethanol (volume ratio: 0.02:1) in turn, stir magnetically, and when the temperature rises to 60°C, add γ-mercapto -Propyltrimethoxysilane and ammonia water, to ensure that the concentrations of the two are 3mL / L and 1mL / L respectively, and after reacting at this temperature for 6h, filter with suction, wash with absolute ethanol, repeat 3 times, and store at 60°C Dry in an oven for 6 hours.

[0050] Such as Figure 7 As shown, it can be seen that the surface morphology of the graphite@Ag composite particles synthesized in Example 3 of the present invention is consistent with the effect of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com