Inner cavity sub-wavelength grating liquid crystal tunable vertical cavity surface emitting laser and preparation method thereof

A technology of vertical cavity surface emission and sub-wavelength grating, which is applied in the direction of lasers, semiconductor lasers, laser components, etc., can solve the problem of wavelength tuning range and tuning ratio limitation of liquid crystal tunable devices, affecting the coupling between semiconductor cavity and liquid crystal cavity, and poor performance Stability and other issues, to achieve the effect of increasing the wavelength tuning range, increasing the energy of the light field, and improving the coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

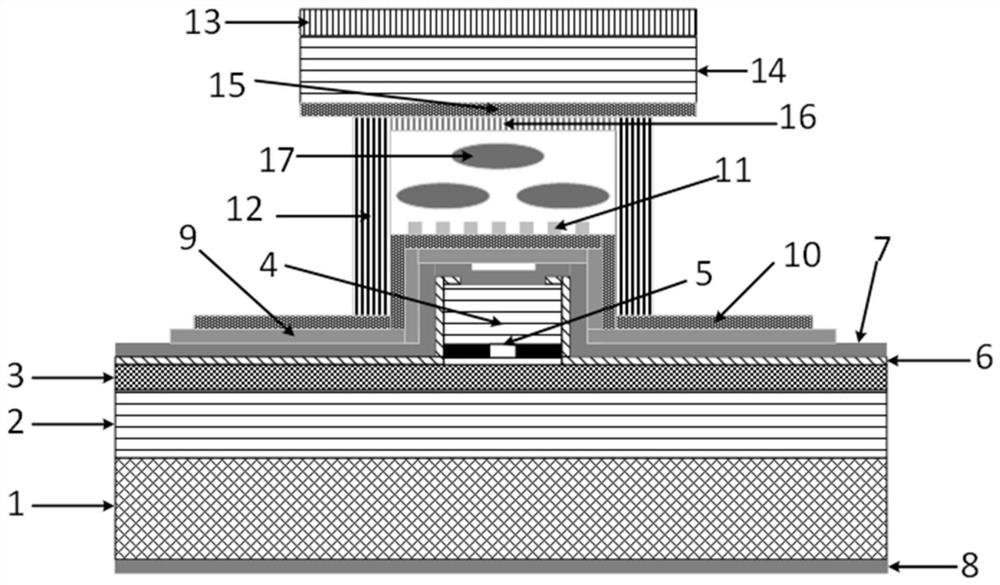

[0047] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the following combination figure 2 -- Figure 16 The preparation method of subwavelength grating liquid crystal tunable vertical cavity surface emitting laser is introduced in detail:

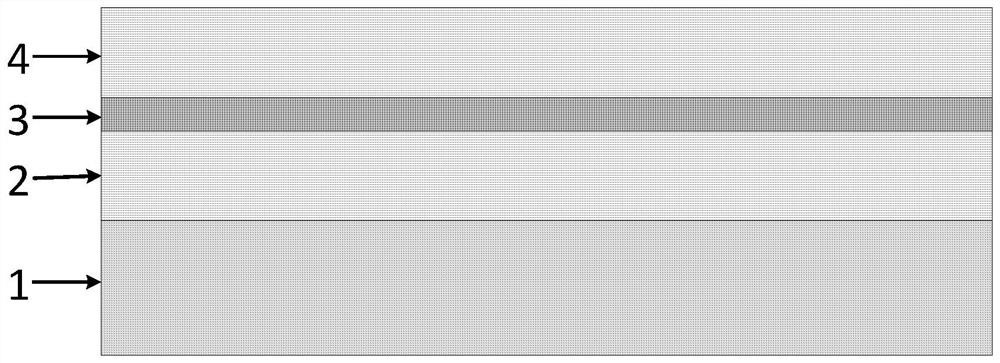

[0048] Step 1. Use metal organic chemical vapor deposition (MOCVD) to alternately grow n-Al on the n-type GaAs substrate 0.9 Ga 0.1 A total of 26 pairs of As layer and n-GaAs layer constitute the lower DBR; re-grow GaAs / In 0.2 Ga 0.8 As quantum well structure constitutes the active region; re-growth Al 0.98 Ga 0.02 The As layer forms an oxidation-limited layer, which limits the distribution of current and light field in the active region; re-grows heavily doped p-type AlGaAs, which facilitates the formation of good ohmic contact with the injection electrode;

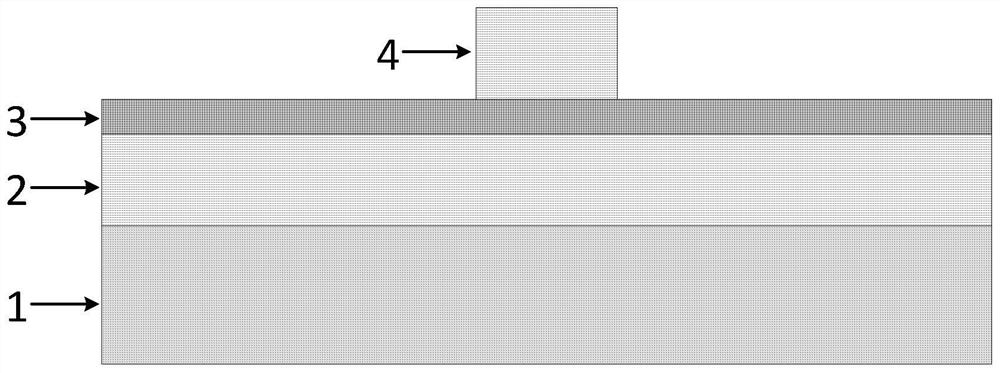

[0049] Step 2. Lithographically etch the laser array pattern on the epitaxial wafer grown in step 1. Use RIE etching to etch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com