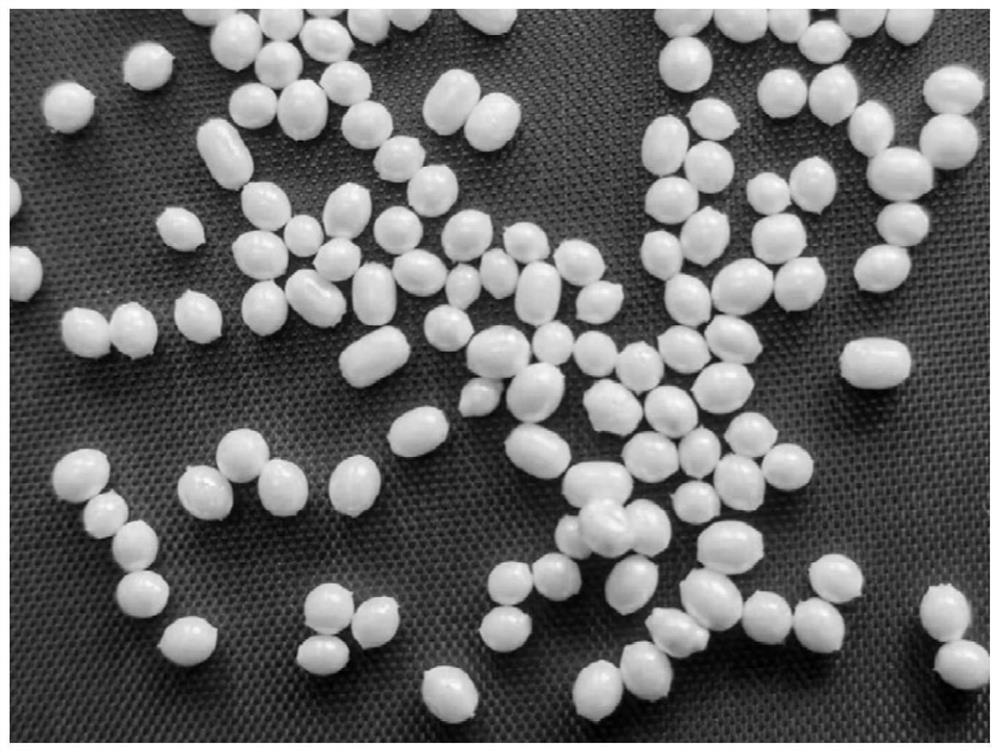

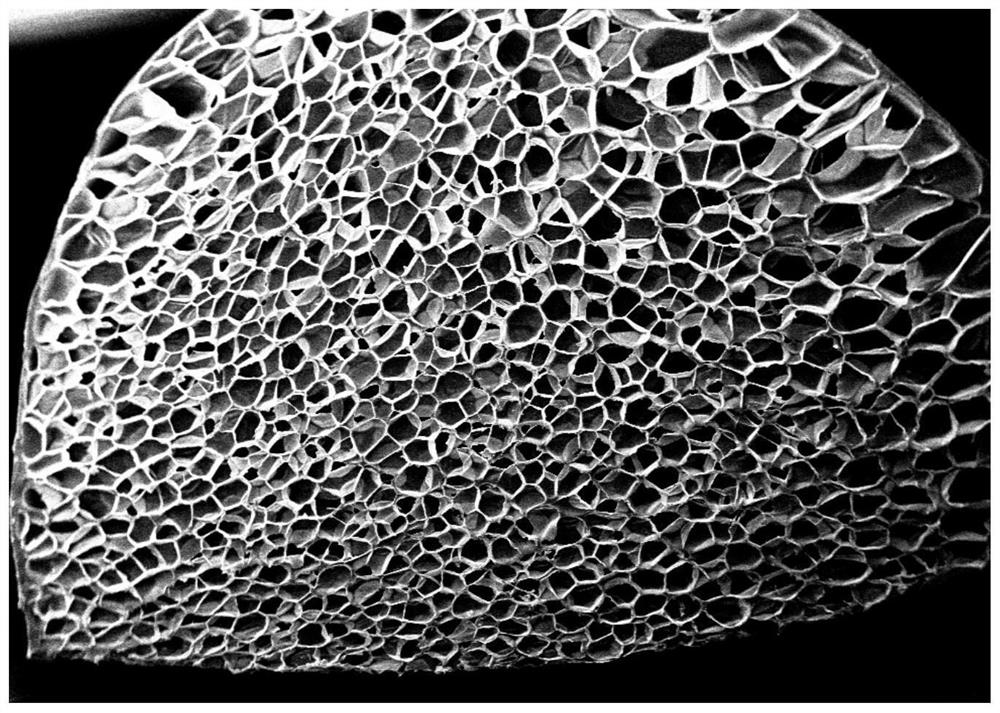

A kind of polyester foam beads and its semi-continuous preparation method and water vapor molding method

An expanded bead, semi-continuous technology, applied in the coating and other directions, can solve the problems of destroying the original geometric shape of PET material, unable to obtain PET expanded beads with complete shape, etc., to inhibit the phenomenon of hydrolysis and thermal oxygen degradation, inhibit the Desorption escape, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The embodiment of the semi-continuous preparation method of polyester expanded beads of the present invention and steam forming method comprises the following steps:

[0072] (1) 100 parts of PET copolyester particles (the third monomer in the copolyester is succinic acid, and the content of the third monomer is 10%), 0.5 part of antioxidant and 0.5 part of hydrolysis resistance agent After successive drying, pre-mixing, twin-screw continuous extrusion and granulation, the precursor polyester particles are obtained;

[0073] (2) Put the precursor polyester particles obtained in step (1) into an anhydrous and filled with CO 2 The impregnated polyester particles with a high-pressure fluid content of 7% and a crystallinity of 5% were obtained by impregnating the fluid in a high-pressure container, and then the impregnated polyester particles were moved into the cooling chamber and subjected to rapid freezing and air-locking treatment with liquid nitrogen. At this time, the...

Embodiment 2

[0081] The embodiment of the semi-continuous preparation method of polyester expanded beads of the present invention and steam forming method comprises the following steps:

[0082] (1) 100 parts of PET copolyester particles (the third monomer in the copolyester is hexanediol, and the content of the third monomer is 5%), 0.5 part of antioxidant and 0.5 part of hydrolysis-resistant agent After successive drying, pre-mixing, twin-screw continuous extrusion and granulation, the precursor polyester particles are obtained;

[0083] (2) Put the precursor polyester particles obtained in step (1) into an anhydrous and filled with CO 2 The impregnated polyester particles with a high-pressure fluid content of 8% and a crystallinity of 8% were obtained by impregnating the fluid in a high-pressure container, and then the impregnated polyester particles were moved into the cooling chamber and quickly frozen and air-locked with liquid nitrogen. At this time, the The temperature is -60°C, a...

Embodiment 3

[0091] The embodiment of the semi-continuous preparation method of polyester expanded beads of the present invention and steam forming method comprises the following steps:

[0092] (1) 60 parts of PET (intrinsic viscosity is 1.0dl / g), 40 parts of PET copolyester particles (the third monomer in the copolyester is succinic acid, and the content of the third monomer is 10% ), 0.5 part of antioxidant and 0.5 part of hydrolysis-resistant agent are sequentially dried, pre-mixed, twin-screw continuous extruded and pelletized to obtain precursor polyester particles;

[0093] (2) Put the precursor polyester particles obtained in step (1) into an anhydrous and filled with CO 2 The impregnated polyester particles with a high-pressure fluid content of 6% and a crystallinity of 5% were obtained by impregnating the fluid in a high-pressure container, and then the impregnated polyester particles were moved into the cooling chamber and quickly frozen and air-locked with liquid nitrogen. At t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com