Nano cuprous oxide and preparation method and application thereof

A technology of nano-cuprous oxide and reaction, applied in botany equipment and methods, copper oxide/copper hydroxide, application, etc., can solve problems such as poor antibacterial performance, and achieve convenient industrial production, excellent antibacterial and kill Influenza virus, the effect of simple and easy-to-control preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The nano cuprous oxide of the present invention will be described in detail below in combination with the preparation method of the nano cuprous oxide of the present invention.

[0038] One embodiment of the present invention provides a method for preparing nano-cuprous oxide, comprising the following steps S10-S20:

[0039] S10: the divalent copper salt and the alkaline substance undergo a metathesis reaction in a solvent to obtain a precipitate. Wherein, the condition of the metathesis reaction is 10° C. to 37° C. for 0.5 h to 4 h.

[0040] Step S10 is carried out under milder conditions by controlling the metathesis reaction of the divalent copper salt and the alkaline substance in the solvent, which is conducive to obtaining a precipitate with a smaller particle size, so as to obtain nanometer-sized cuprous oxide.

[0041] In some of these embodiments, the condition of the metathesis reaction is preferably 10°C-37°C for 0.5h-4h. Within this preferred range, it is ...

Embodiment 1~9

[0083] Step 1. Take 9 parts of 100mL 0.1mol / L copper sulfate solution, add 15mL of 1mol / L potassium hydroxide solution respectively, and stir at 10°C under normal pressure for 0.5h, 1h and 4h respectively; or 25°C Stirring under normal pressure, the reaction duration is 0.5h, 1h and 4h respectively; The obtained substrate was centrifuged at 7500r / min, and the resulting precipitate was washed three times with deionized water, all of which were blue in color.

[0084] Step 2: Add 9 parts of the substrate obtained in Step 1 to 100 mL of water and stir to disperse evenly, then gradually add 20 mL of 0.02 mol / L sodium borohydride aqueous solution, respectively, stir at 10°C under normal pressure, and the reaction duration is 0.5 h , 1h and 4h; or stir under normal pressure at 25°C, the reaction duration is 0.5h, 1h and 4h respectively; or stir at 37°C under normal pressure, the reaction duration is 0.5h, 1h and 4h respectively, 7500r / min Nine parts of products were obtained by cen...

Embodiment 10~12

[0090] The preparation technology of embodiment 10~12 is basically the same as embodiment 5, and difference only is:

[0091] In step 1, the dosage of 1 mol / L potassium hydroxide solution was 20 mL, 25 mL and 35 mL respectively, and the mixture was stirred for 1 h at 25°C under normal pressure, and the obtained precipitates were all blue; the products obtained in step 2 were all yellow-green cuprous oxide nanoparticles.

[0092] Examples 1-12 show that controlling the ratio of the amount of copper salt, alkali and reducing agent to 1:(1.5-3.5):0.04, the products obtained are all yellow-green cuprous oxide nanoparticles.

PUM

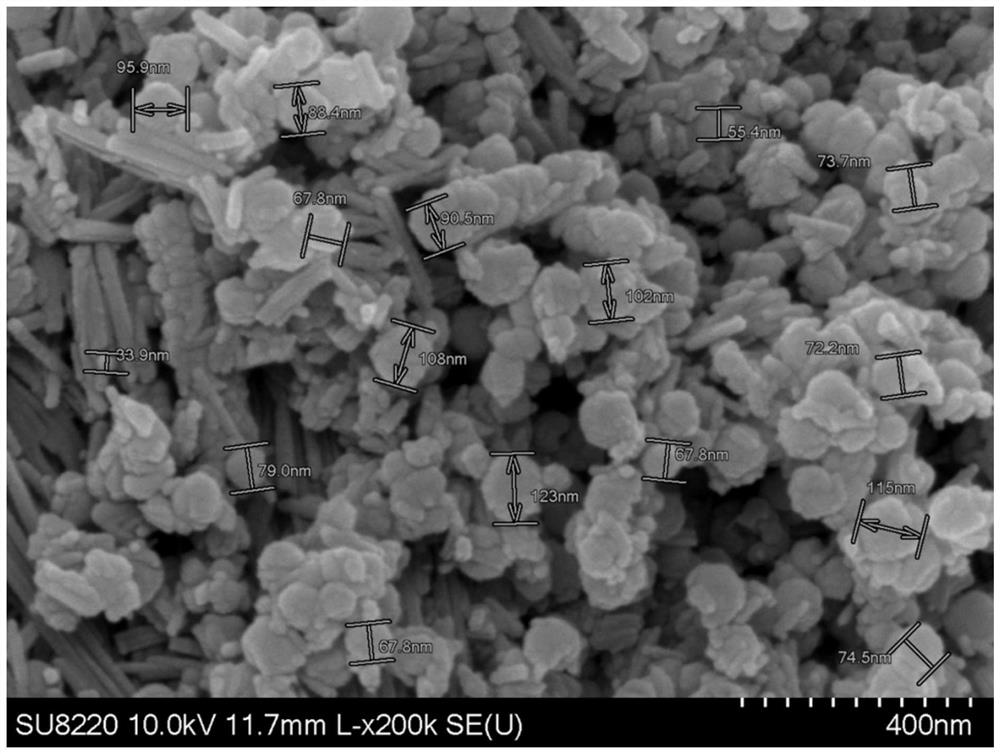

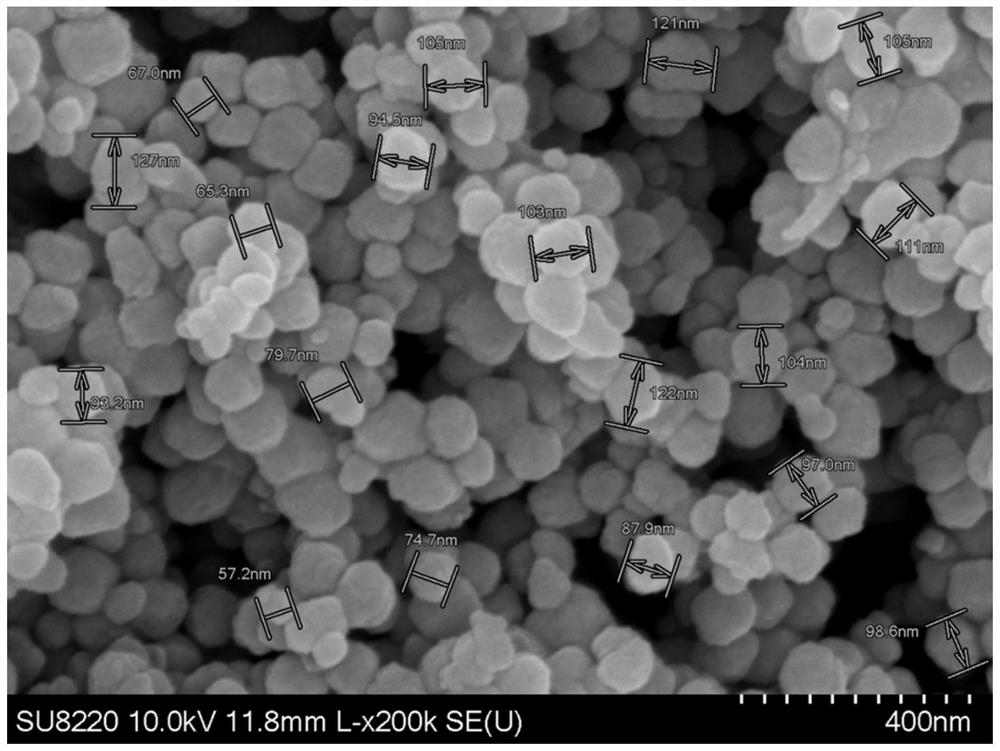

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com