Artificial marble with fragrance and preparation method thereof

An artificial marble and fragrance technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of short fragrance emission period, adverse environmental impact, uneven fragrance, etc., to accelerate the curing effect and improve Environment, effect of improving compressive strength and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

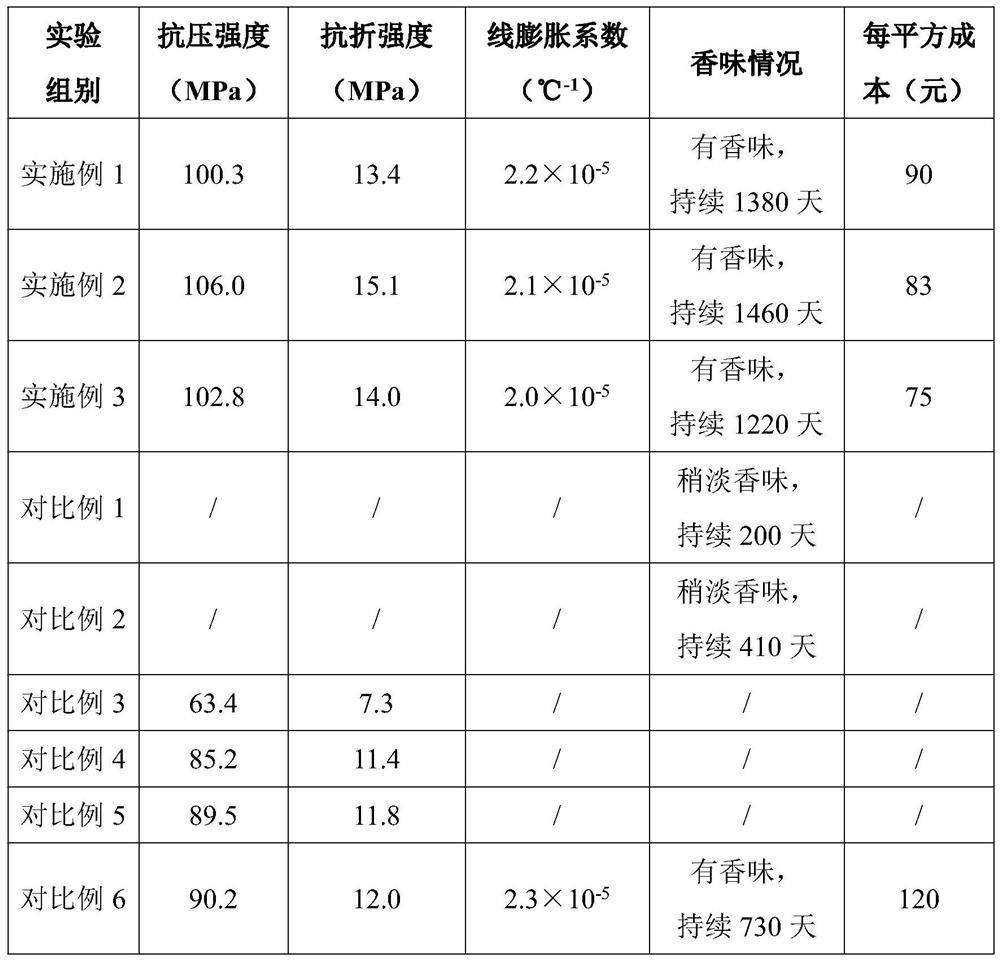

Examples

preparation example Construction

[0033] The preparation method of described artificial marble with fragrance comprises the following steps:

[0034] (1) Add microbial preparations to the spice waste residue to make the fragrance fully distributed, and prepare the treated spice waste residue. The mass ratio of the spice waste residue to the microbial preparation is 3000-5000:1, and the microbial preparation is composed of Acidophilus and Bacillus subtilis are inoculated with trehalose and prepared by centrifugation. The mass ratio of acidophilus, Bacillus subtilis and trehalose is 1-1.5:1-1.5:2-3. The centrifuged The speed is 3500-6000r / min;

[0035] (2) Put the spice waste residue treated in step (1) into a grinder and grind it to 70-90 mesh small particles to obtain pulverized spice waste residue.

[0036] (3) Add the crushed spice waste residue, calcium carbonate filler, additives, pigments, and resin obtained in step (2) into the mixer, and stir at a stirring frequency of 30-50Hz and a rotating speed of 3...

Embodiment 1

[0040] An artificial marble with fragrance, comprising the following raw materials in percentage by weight: 8.3% of fragrance waste residue, 0.3% of additives, 61% of calcium carbonate filler, 10.4% of pigment, and 20% of resin;

[0041] Described auxiliary agent comprises auxiliary agent a, auxiliary agent b, auxiliary agent c;

[0042] The auxiliary agent a is formed by mixing ethyl maltol and furfuryl mercaptan in a mass ratio of 2:3, and the addition amount is 0.1%;

[0043] The auxiliary agent b is formed by mixing cyclohexanone peroxide and methyl isobutyl ketone peroxide in a mass ratio of 3:2, and the addition amount is 0.1%;

[0044] The auxiliary agent c is formed by mixing cobalt isooctanoate and N,N-dimethylaniline in a mass ratio of 2:1, and the addition amount is 0.1%;

[0045] The pigment is iron yellow;

[0046] The resin is an unsaturated polyester resin, and the unsaturated polyester resin is synthesized by including maleic anhydride, phthalic anhydride and p...

Embodiment 2

[0053] An artificial marble with fragrance, comprising the following raw materials in percentage by weight: 9.2% of fragrance waste residue, 5.6% of additives, 54.4% of calcium carbonate filler, 12.5% of pigment, and 18.3% of resin;

[0054] Described auxiliary agent comprises auxiliary agent a, auxiliary agent b, auxiliary agent c;

[0055] The auxiliary agent a is formed by mixing ethyl maltol, furanone and furfuryl mercaptan in a mass ratio of 1:3:2, and the addition amount is 0.12%;

[0056] The auxiliary agent b is formed by mixing methyl ethyl ketone peroxide, cyclohexanone peroxide, and methyl isobutyl ketone peroxide in a mass ratio of 4:3:1, and the addition amount is 0.24%;

[0057] The auxiliary agent c is formed by mixing cobalt naphthenate, cobalt isooctanoate, N,N-dimethylaniline and N,N-diethylaniline in a mass ratio of 4:2:1:3, and the addition amount is 0.2%;

[0058] Described pigment is iron yellow, iron red, and the amount ratio of described iron yellow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com