Ceramic room-temperature sintering method

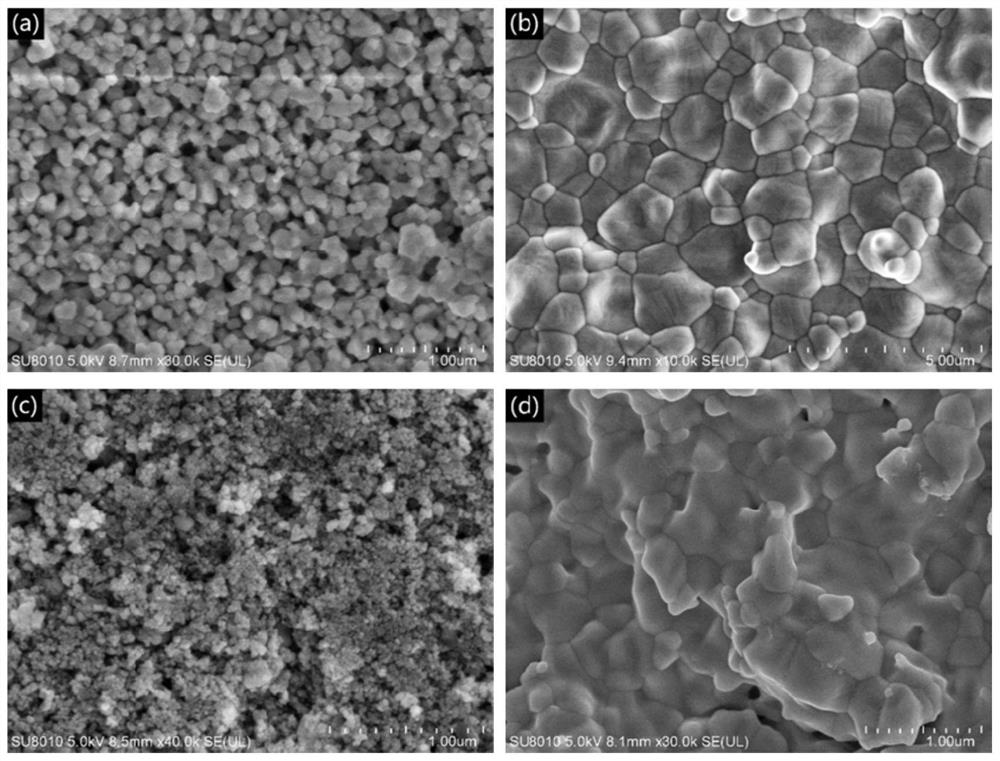

A sintering method and ceramic technology, which is applied in the field of ceramic sintering at room temperature, can solve the problems of difficulty in preparing nano-ceramic materials, excessive ceramic grains, etc., and achieve the effect of reducing the average grain size and increasing the relative density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The concept, specific structure and technical effects of the present disclosure will be clearly and completely described below in conjunction with the embodiments and drawings, so as to fully understand the purpose, scheme and effect of the present disclosure. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

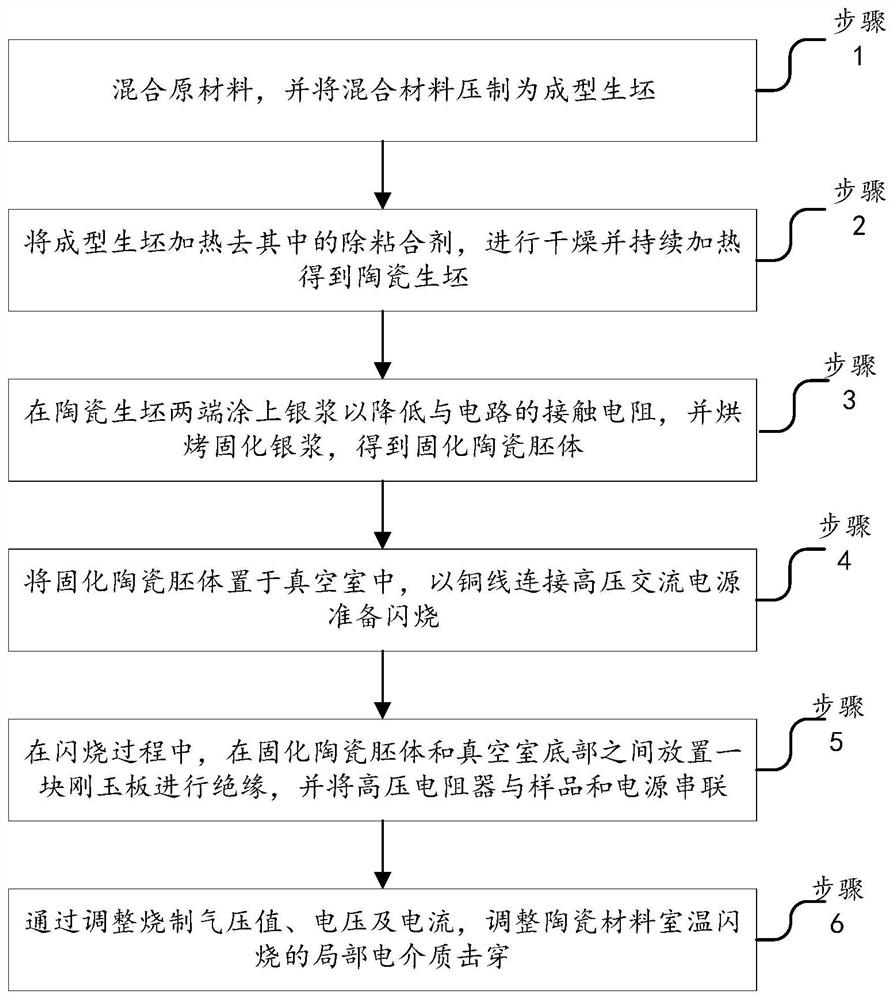

[0026] like figure 1 Shown is a flow chart of a ceramic room temperature sintering method according to the present disclosure, combined below figure 1 A room temperature sintering method for ceramics according to an embodiment of the present disclosure will be described.

[0027] The present disclosure proposes a method for sintering ceramics at room temperature, which specifically includes the following steps:

[0028] Step 1, mixing raw materials, and pressing the mixed materials into a shaped green body;

[0029] Step 2, heating the molded gree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com