Preparation method of antiviral packaging paper

A wrapping paper and anti-virus technology, applied in the directions of wrapping paper, wrapping paper, packaging, etc., can solve the problems of inability to guarantee simultaneous protection, waste of wrapping paper, and deviation of cutting specifications, and achieve the effect of reducing the possibility of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

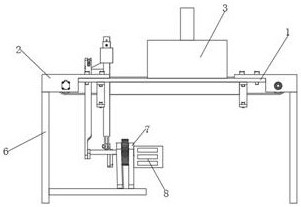

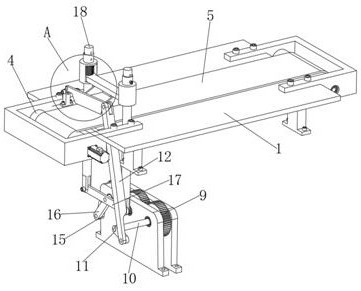

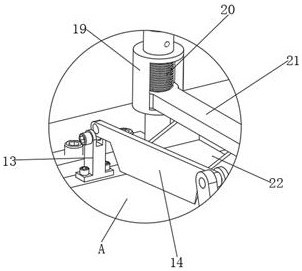

[0026] see Figure 1~Figure 4 , a preparation method of antiviral wrapping paper, the concrete operation steps of this preparation method are as follows:

[0027] Step 1: Put wood pulp, hardwood pulp and kaolin through disc grinding and beating, add dilution water, wet strength agent, retention aid and pulp sizing agent to the pulp, and remove the pulp from the pulp through a slag remover and a pressure screen After being diluted with water by the frequency conversion pulp pump for the second time, it is sent to the paper headbox to distribute the pulp evenly and then go online. It is formed and dehydrated in the box and vacuum couch roll, and then dehydrated by pressing, and the packaging base paper is obtained after being contacted and dried by the steam dryer;

[0028] Step 2: The packaging base paper is transported to the sizing equipment for surface sizing. The sizing agent is made of corn starch glue and Ankevit concentrate according to the scientific formula. The main ...

Embodiment approach

[0033] As an embodiment of the present invention, the flattening mechanism 3 includes a U-shaped seat 23, a cylinder body 24, a second spring 25, a movable rod 26, a roller seat 27 and a pressure roller 28, and a cylinder is installed through the top side of the U-shaped seat 23. body 24, a second spring 25 is installed inside the cylinder body 24, the second spring 25 is connected to the bottom end of the movable rod 26, and the bottom end of the movable rod 26 is located below the cylinder body 24 and a roller seat 27 is installed, and the bottom side of the roller seat 27 is installed horizontally There are several pressure rollers 28, and the second spring 25 in the cylinder body 24 of the flattening mechanism 3 stretches and drives the movable rod 26 and the roller seat 27 to move, and then presses the flattened and dried preliminary paper on the transmission belt 5 through the pressure rollers 28 , which plays a limiting role in the preliminary paper movement, avoiding th...

Embodiment 2

[0038] A preparation method of antiviral wrapping paper, the specific operation steps of the preparation method are as follows: pass the hydrotalcite through a 40-mesh sieve, and add the hydrotalcite to the long carbon chain anionic surfactant dodecane with a concentration of 0.5mol / L In the sodium dodecyl sulfonate solution, the volume of sodium dodecyl sulfonate solution corresponding to each gram of hydrotalcite is 2mL, stirred in a water bath at 50°C for 2h; then add the short carbon chain anionic surfactant sodium butyrate, Add 0.2mmol short carbon chain anionic surfactant, then stir in 50°C water bath for 2h, filter the product, wash with distilled water, filter dry, dry at 90°C, and activate at 105°C for 30min; grind, pass 50 mesh sieves, obtained the organic hydrotalcite prepared by double anionic surfactant modification;

[0039] Add the prepared dianion surfactant-modified hydrotalcite into 25mg / L nitrobenzene, the solid-liquid (mass) ratio is 1:2000, stir for 2h, le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com