Ibuprofen granules and preparation method thereof

A technology of granules and disintegrants, applied in the field of ibuprofen granules and its preparation, to achieve a simple and reliable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

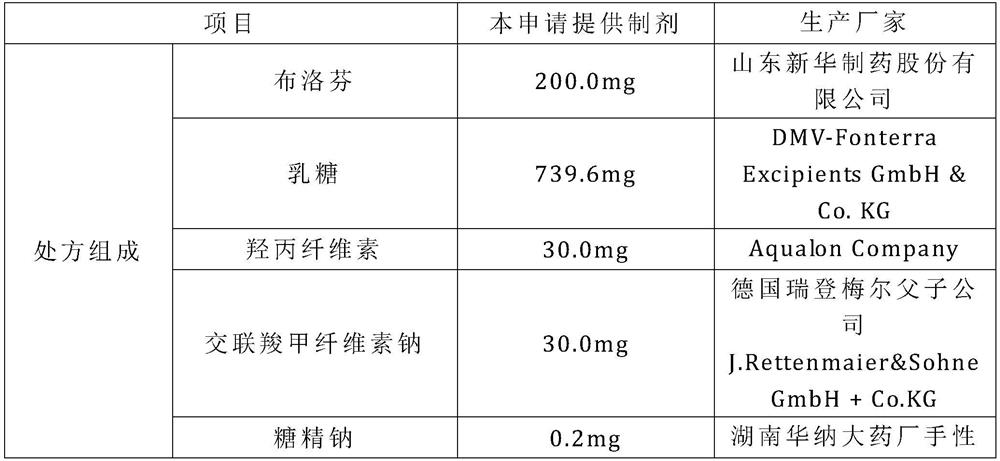

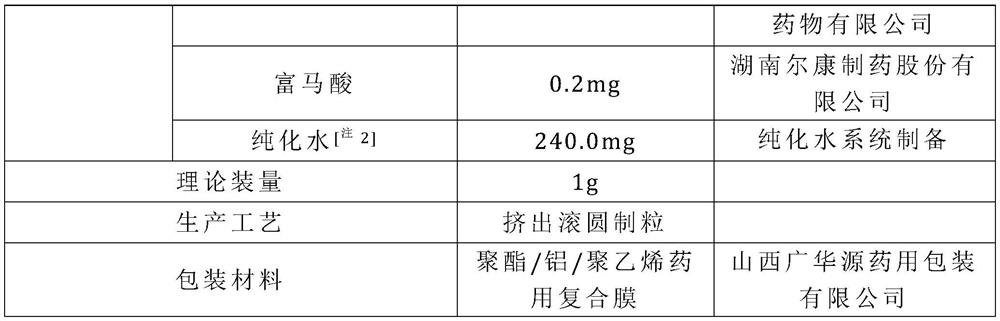

preparation example Construction

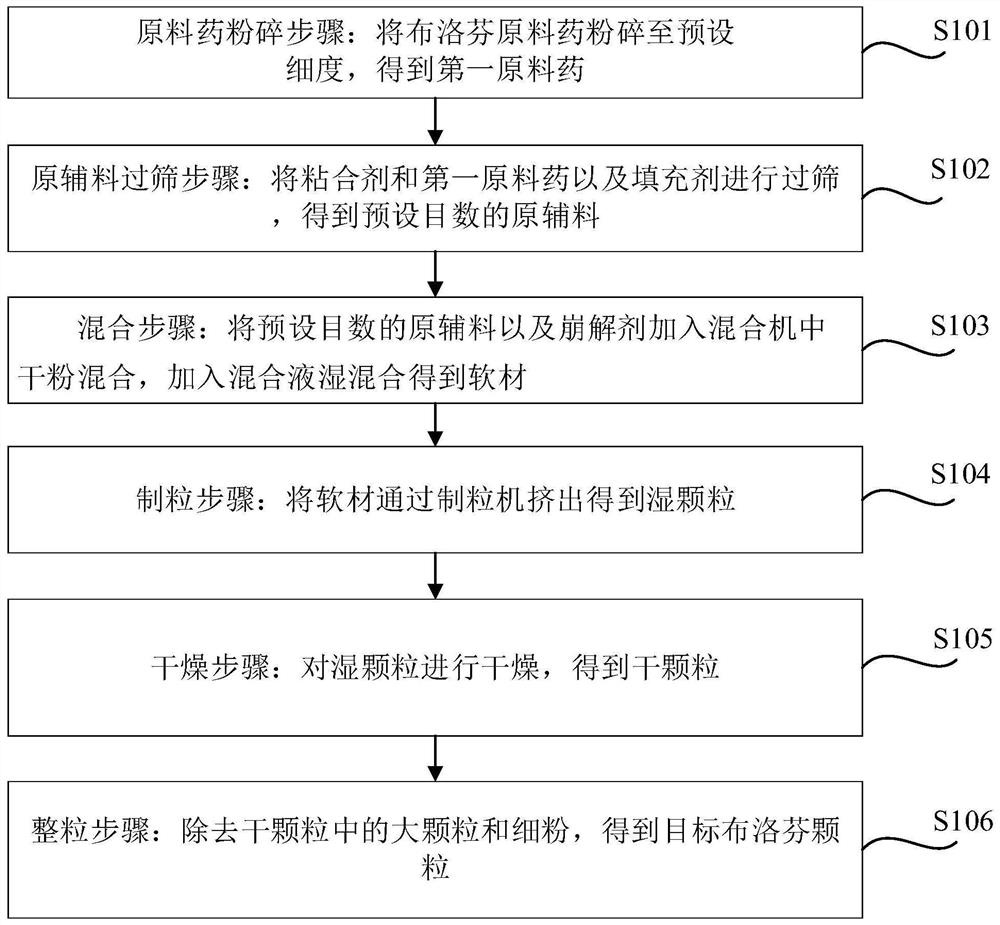

[0038] On the other hand, the embodiment of the present application also provides a method for preparing ibuprofen granules, the method for preparing ibuprofen granules comprises:

[0039] S101. Crushing step of the crude drug: pulverize the ibuprofen crude drug to a preset fineness to obtain the first crude drug.

[0040] S102. The step of sieving raw and auxiliary materials: sieving the binder, the first bulk drug and the filler to obtain raw and auxiliary materials with a predetermined mesh number.

[0041] S103. Mixing step: adding the first bulk drug, binders of preset meshes, fillers and disintegrants into the mixer for dry powder mixing, and adding the mixed liquid for wet mixing to obtain a soft material.

[0042] S104. Granulating step: extruding the soft material through a granulator to obtain wet granules.

[0043] S105. Drying step: drying the wet granules to obtain dry granules.

[0044] S106. Grain sizing step: removing large particles and fine powder in the dr...

Embodiment

[0074] (1) Crushing of raw materials: set the current of the classifying motor of the airflow pulverizer to 2A, the frequency of the classifying wheel to 80 Hz, and the frequency of feeding to 20 Hz. The raw material should reach the preset fineness (the particle size test report of the ibuprofen raw material: the fineness is 2μm≤D50≤18μm, 4μm≤D90≤56μm).

[0075] (2) Screening of raw and auxiliary materials: hydroxypropyl cellulose and pulverized ibuprofen raw materials are sieved by hand with a mesh number of 20; 20 mesh.

[0076] (3) Ingredients: Check the names, serial numbers and weights of raw and auxiliary materials before ingredients, and put them in double-layer low-density polyethylene bags according to the batch amount.

[0077] (4) Preparation of fumaric acid and sodium saccharin mixed solution: Fumaric acid, sodium saccharin, and purified water are prepared in a ratio of 1:1:1200 to make a solution for later use (dissolve fumaric acid and sodium saccharin with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com