A kind of preparation method and application of high entropy nanozyme

A nanozyme and high-entropy technology, applied in the field of high-entropy nanozyme preparation, achieves the effect of simple method, excellent activity and good medical application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

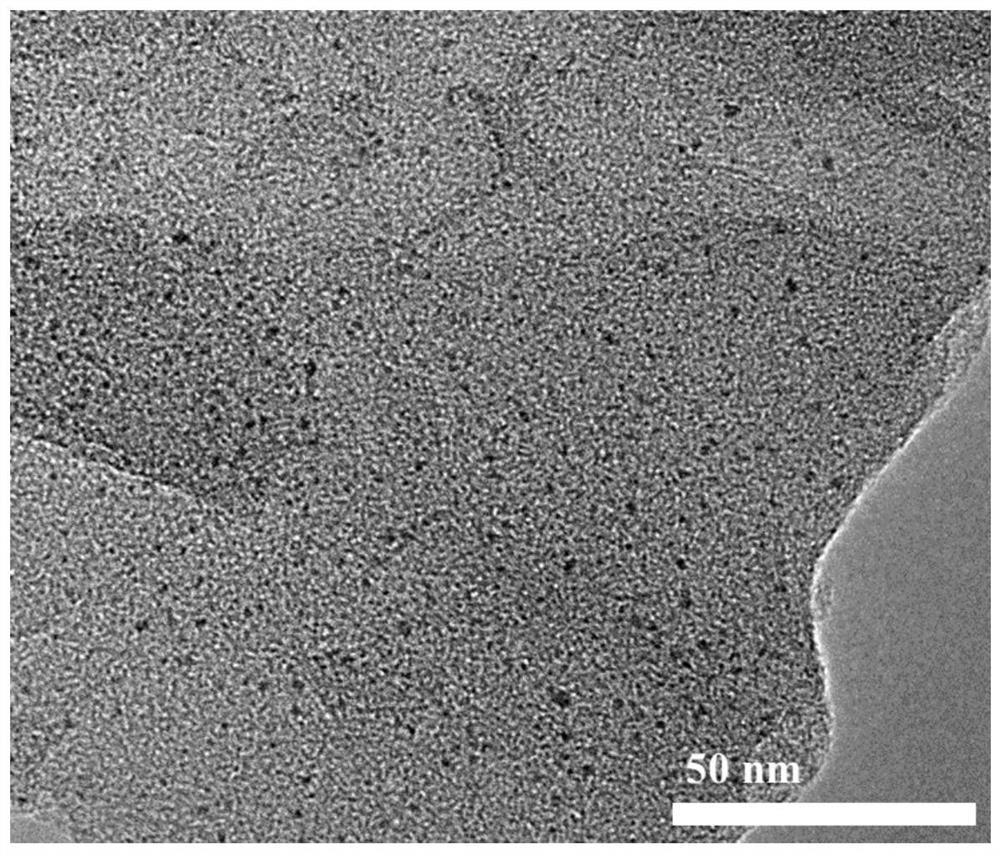

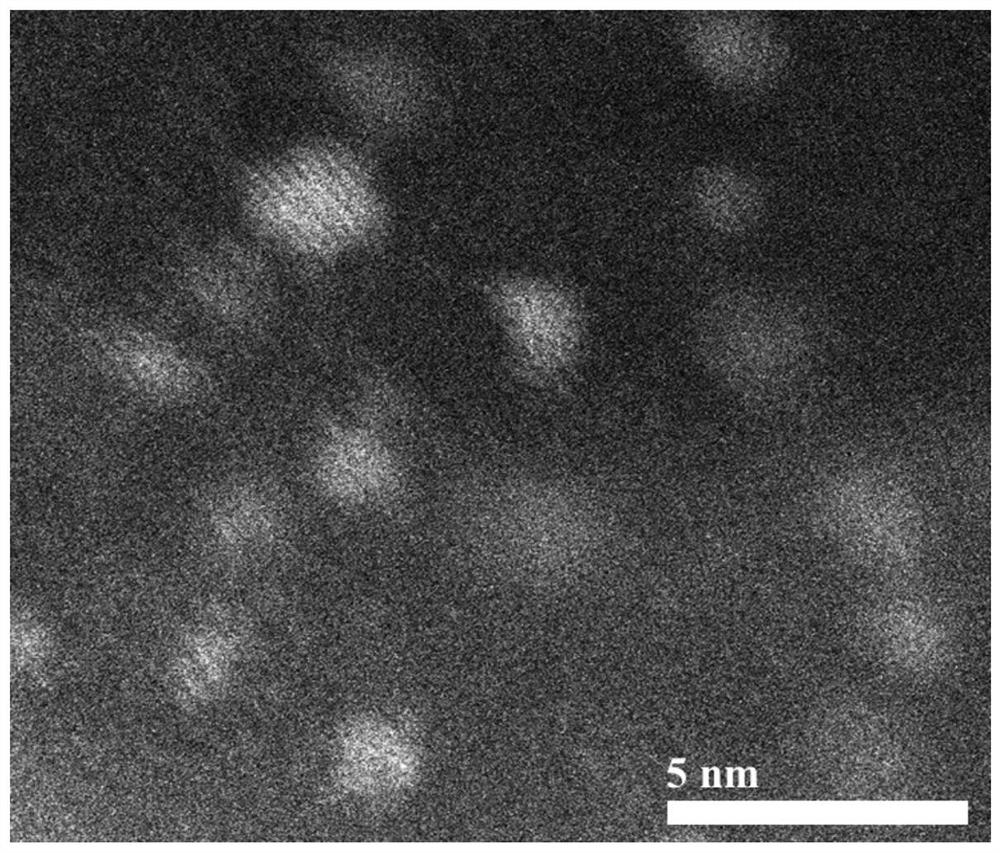

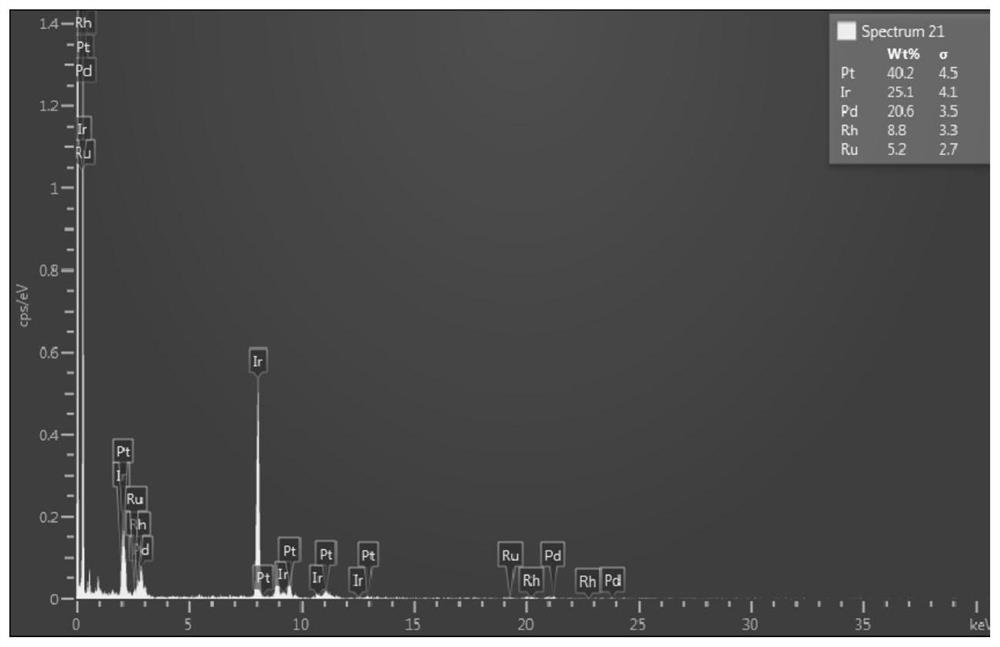

Image

Examples

preparation example Construction

[0015] The preparation method of the high-entropy nanozyme proposed by the present invention comprises the following steps:

[0016] (1) Five compounds of ruthenium acetylacetonate, rhodium acetylacetonate, palladium acetylacetonate, platinum acetylacetonate and iridium acetylacetonate are poured into the acetylacetone solution, and the mass ratio of the mixed solution is: acetylacetone: ruthenium acetylacetonate: acetylacetonate Rhodium: palladium acetylacetonate: platinum acetylacetonate: iridium acetylacetonate = 1: (0.02~0.001): (0.02~0.001): (0.02~0.001): (0.02~0.001): (0.02~0.001); the utilization power is 250W The mixed solution was ultrasonically treated for 10 minutes. After the compound in the reaction solution was fully dissolved, it was stirred with a magnetic stirrer at a stirring speed of 600 rpm for 10 to 30 minutes to obtain the first solution;

[0017] (2) Add a surfactant in the first solution, and use a power of 250W to ultrasonically treat the mixed solutio...

Embodiment 1

[0029] (1) Five compounds of ruthenium acetylacetonate, rhodium acetylacetonate, palladium acetylacetonate, platinum acetylacetonate and iridium acetylacetonate are poured into the acetylacetone solution, and the mass ratio of the mixed solution is acetylacetonate: ruthenium acetylacetonate: rhodium acetylacetonate : palladium acetylacetonate: platinum acetylacetonate: iridium acetylacetonate = 1:0.02:0.02:0.02:0.02:0.02. Ultrasonic treatment of the mixed solution with a power of 250W for 10 minutes, after the compound in the reaction solution is fully dissolved, stirred for 10 minutes with a magnetic stirrer at a stirring speed of 600 rpm to obtain the first solution;

[0030] (2) Add the surfactant cetyltrimethylammonium chloride in the first solution, and use a power of 250W to ultrasonically treat the mixed solution for 10 minutes. After the surfactant in the reaction solution is fully dissolved, the stirring speed Stir with a magnetic stirrer at 600 rpm for 10 minutes so ...

Embodiment 2

[0034](1) Five compounds of ruthenium acetylacetonate, rhodium acetylacetonate, palladium acetylacetonate, platinum acetylacetonate and iridium acetylacetonate are poured into the acetylacetone solution, and the mass ratio of the mixed solution is acetylacetonate: ruthenium acetylacetonate: rhodium acetylacetonate : palladium acetylacetonate: platinum acetylacetonate: iridium acetylacetonate = 1:0.001:0.001:0.001:0.001:0.001. Ultrasonic treatment of the mixed solution with a power of 250W for 10 minutes, after the compound in the reaction solution is fully dissolved, stirred for 10 minutes with a magnetic stirrer at a stirring speed of 600 rpm to obtain the first solution;

[0035] (2) Add the surfactant cetyltrimethylammonium chloride in the first solution, and use a power of 250W to ultrasonically treat the mixed solution for 10 minutes. After the surfactant in the reaction solution is fully dissolved, the stirring speed Stir with a magnetic stirrer at 600 rpm for 10 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com