Fast food bag capable of improving microwave heating uniformity

A microwave heating and uniformity technology, applied in the field of instant food bags, can solve the problems of reducing product recognition, affecting food taste, affecting food quality, etc., and achieving the effect of improving temperature distribution uniformity, increasing minimum temperature and good food taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

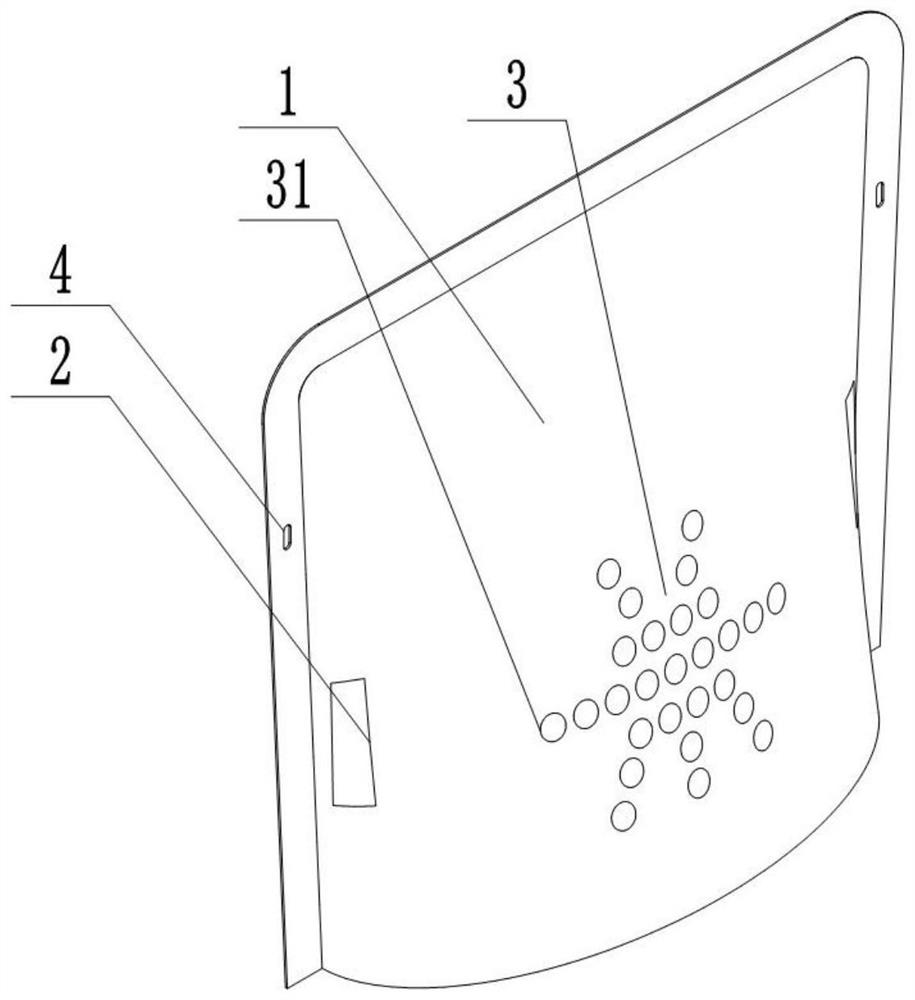

[0030] refer to Figure 1-3 , the present invention provides an instant food bag capable of improving the uniformity of microwave heating, including a main body 1, a heat conducting part 3 and a shielding strip 2;

[0031] Body 1, body 1 is a bag-shaped structure, which is used to seal and hold food. After the food is cooked, put it into body 1 and seal it. When eating, it can be heated in a microwave oven; Each of the sealing edges is 10mm wide, the cross-section of the body 1 is triangular, and the width of the bottom is 80mm;

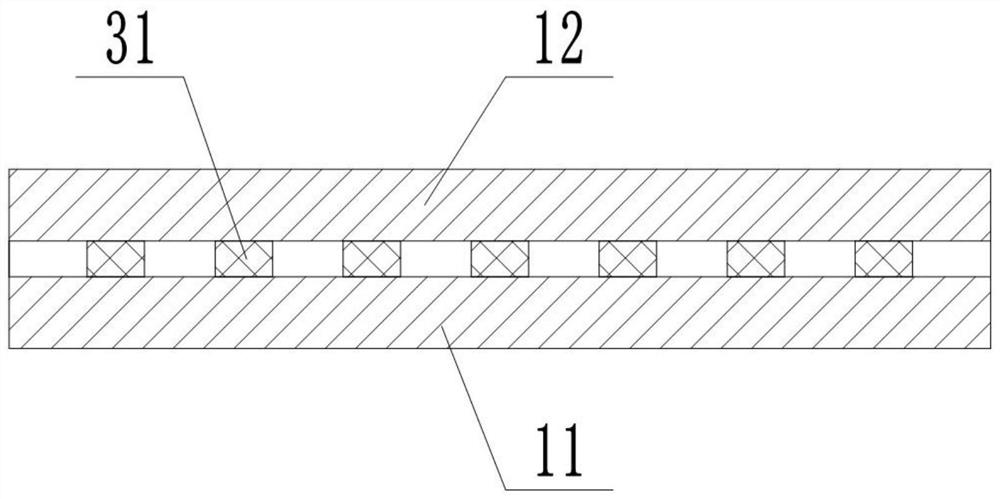

[0032] The heat conduction part 3, the heat conduction part 3 is respectively arranged on the front and rear ends of the body 1, and is used to improve the heat conduction efficiency and heat conduction uniformity; the heat conduction part 3 includes a plurality of arrays of heat conduction sheets 31, and the material of the heat conduction sheets 31 is metal, specifically aluminum The center of the heat conduction part 3 is arranged on the center l...

Embodiment 2

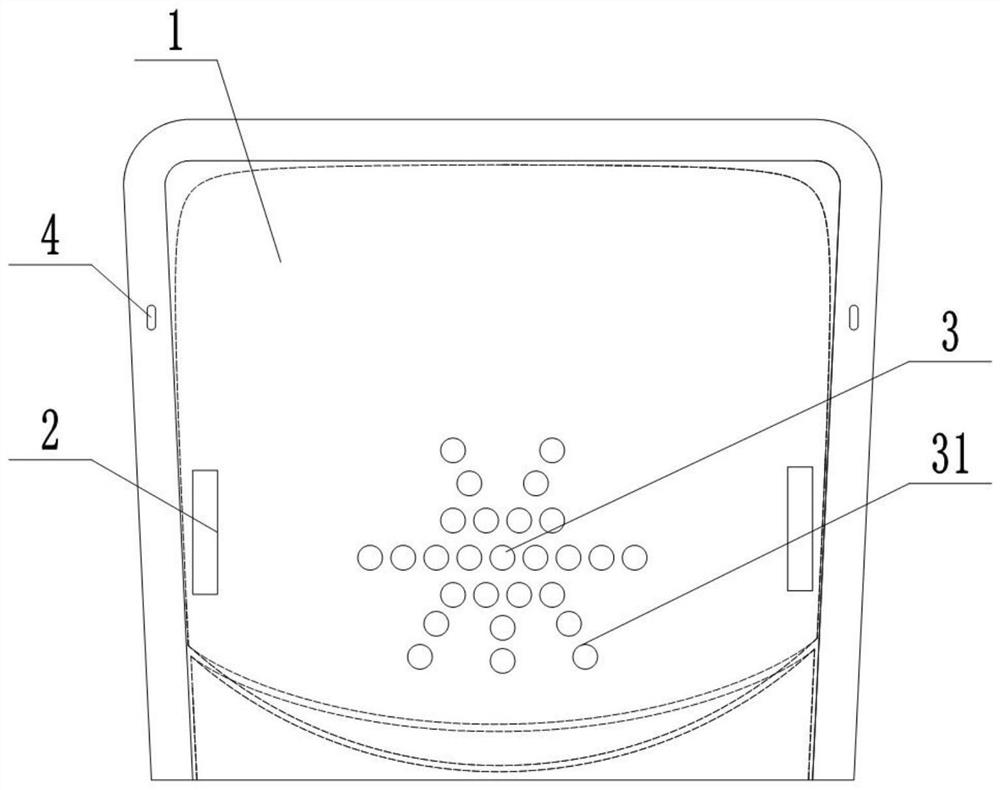

[0045] refer to Figure 3-5 The difference between this embodiment and Embodiment 1 is that the arrangement of the heat conduction parts 3 in this embodiment is to distribute in the central low-temperature area according to the number of 7, 6, 7, and 6. In order to ensure the structure is symmetrical and common Use 26 pieces of heat conduction fins 31; the arrangement structure of heat conduction fins 31 in embodiment 1 has a large number of rows, and the structure is relatively complicated, which is easy to reduce production efficiency. The quantity used is less than that of Example 1, which reduces the production cost.

[0046] Existing instant bag of table 2 and embodiment 2 result contrast

[0047]

[0048] It can be seen from Table 2 that the average temperature is increased by 15.82°C in Example 2, and the standard deviation of the temperature is decreased by 11.1°C. The distribution of heat conduction sheets 31 in Example 2 is relatively dense, so the continuity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com