A kind of preparation method of sulfur silver germanium ore type sulfide solid state electrolyte

A solid-state electrolyte, silver-sulfur germanium ore technology, applied in the field of lithium-ion batteries, can solve the problems of low ionic conductivity of solid-state electrolyte, easy to stick to the tank wall and spherical surface, unable to obtain the expected crystal phase, so as to reduce CO2 escape. , to avoid uneven mixing of materials, to avoid the effect of solvent difficult to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

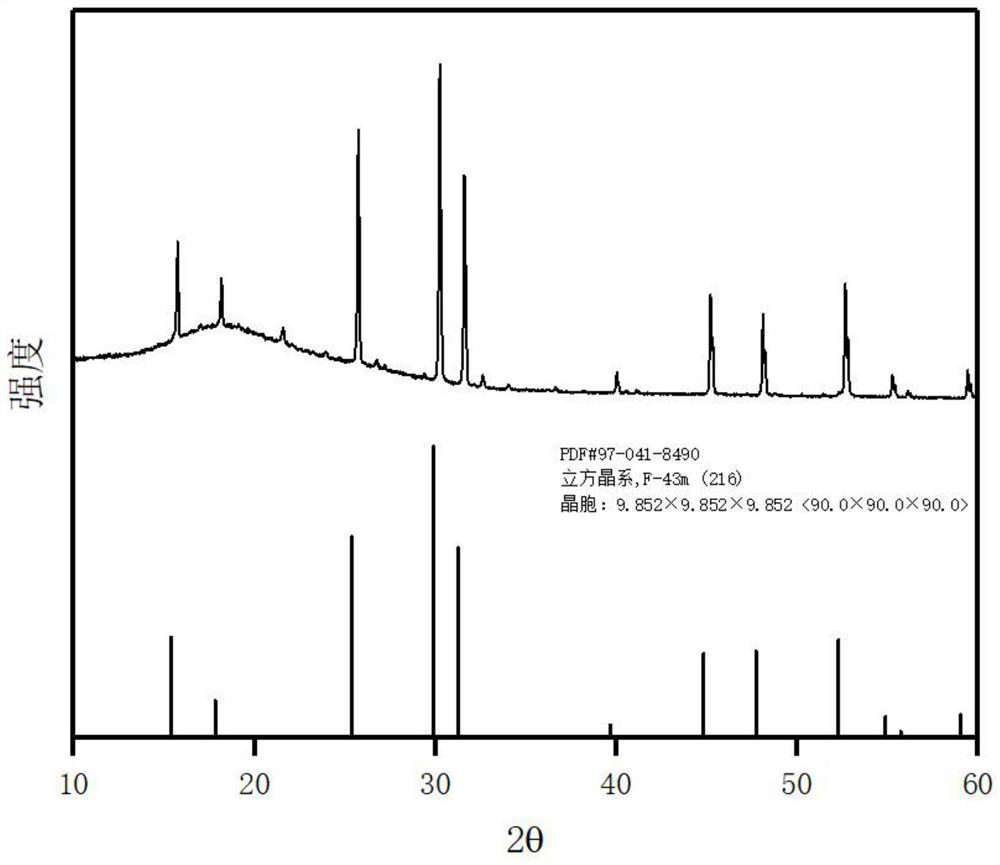

[0027] Weigh 2N pure reagent Li according to the stoichiometric ratio of 5:2:6:2 2 O 2 , P, CS 2 and LiCl, put into a zirconia ball mill with an air valve in turn, add zirconia balls with a ball-to-material ratio of 40:1, seal the ball mill and vacuumize it, vacuum degree 6 PS 5 Cl solid electrolyte powder. figure 1 is the XRD pattern of the solid electrolyte powder. The solid electrolyte powder is pressed under a pressure of 200Mpa, and the pressure is maintained for 3 minutes to obtain a solid electrolyte sheet. The whole process was carried out under an argon protective atmosphere. The lithium electrical conductivity of the solid electrolyte sheet at room temperature is 3.2×10 -3 S cm -1 .

Embodiment 2

[0029] Weigh 2N pure reagent Li according to the stoichiometric ratio of 5:2:5:2 2 O 2 , P, CS 2 and LiCl, put into a zirconia ball mill with an air valve in turn, add zirconia balls with a ball-to-material ratio of 30:1, seal the ball mill and vacuumize it, the degree of vacuum is less than -0.09MPa, and then put it into a planetary ball mill Carry out ball milling, the ball milling speed is 800r / min, the ball milling is 15 hours, and the ball mill tank is evacuated every 3 hours, and the vacuum degree is less than -0.09MPa. Then take out the initial electrolyte material and put it in an electric furnace to heat up to 300°C at a rate of 10°C / min, keep the temperature for 3 hours, put it into a mortar for natural cooling and grind it, and pass through a 400-mesh sieve to obtain Li 6 PS 5 Cl solid electrolyte powder. The solid electrolyte powder is pressed under a pressure of 200Mpa, and the pressure is maintained for 3 minutes to obtain a solid electrolyte sheet. The whol...

Embodiment 3

[0031] Weigh 2N pure reagent Li according to the stoichiometric ratio of 5:1:6:2 2 O.P 2 O 5 , CS 2 and LiCl, put into a zirconia ball mill with an air valve in turn, add zirconia balls with a ball-to-material ratio of 40:1, seal the ball mill and vacuumize it, vacuum 6 PS 5 Cl solid electrolyte powder. figure 1 is the XRD pattern of the solid electrolyte powder. The solid electrolyte powder is pressed under a pressure of 200Mpa and maintained for 3 minutes to obtain a solid electrolyte sheet. The whole process was carried out under an argon protective atmosphere. The lithium conductivity of the solid electrolyte sheet at room temperature is 1.3×10 -3 S cm -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com