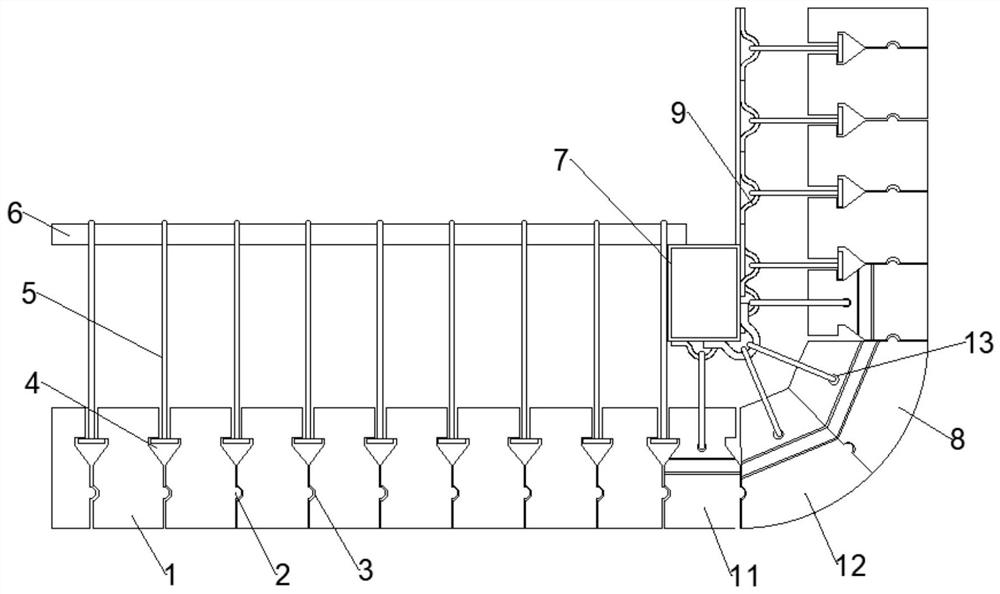

Refractory material for grate cooler, suspension structure and construction method

A technology of refractory materials and suspension structures, applied in the field of grate coolers, can solve the problems of short service life, poor refractory effect, and short service life of grate coolers, and improve poor refractoriness, facilitate subsequent disassembly, Effect of improving flexural strength and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

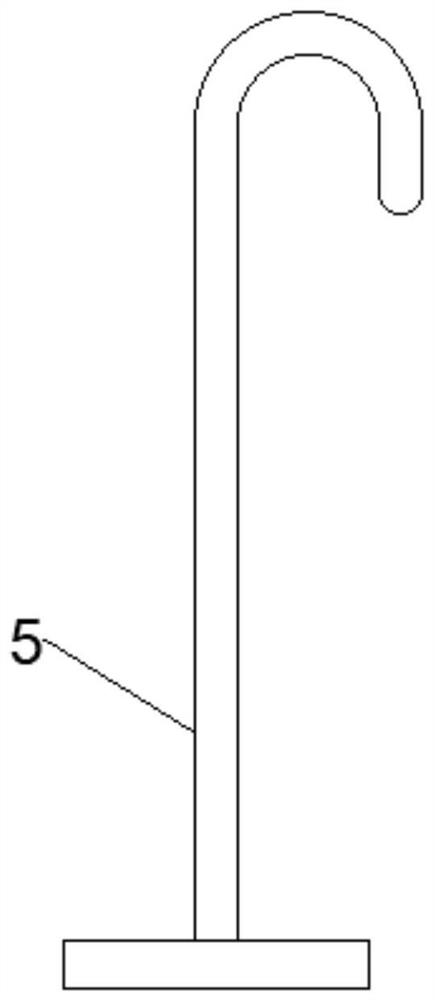

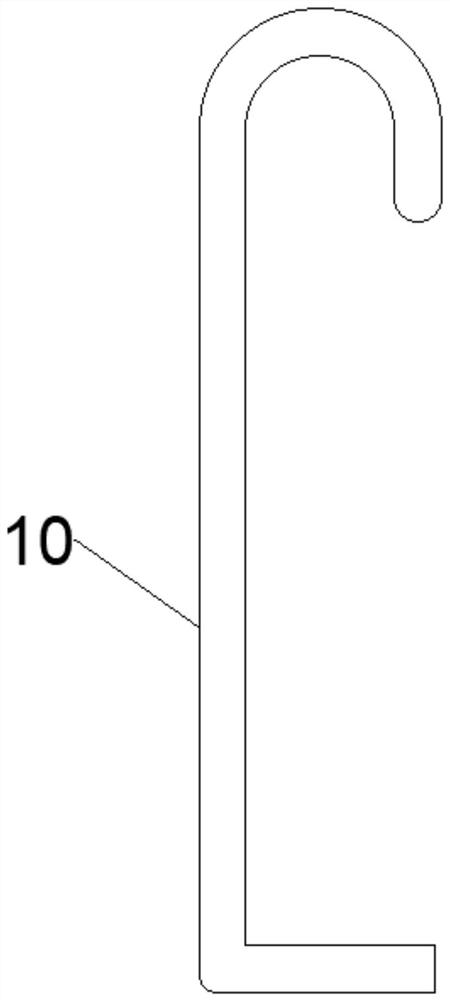

Method used

Image

Examples

Embodiment 1

[0034] In an embodiment of the present invention, a refractory material for a grate cooler, the refractory material for a grate cooler includes the following raw materials in parts by weight: 80 parts of high-purity mullite, 60 parts of clay, 20 parts of large particle andalusite, small particle 6 parts of andalusite, 16 parts of cermet, 6 parts of fused mullite, 12 parts of white corundum, 4 parts of α-alumina, 2 parts of magnesium silicate, and 6 parts of binder.

[0035] The binding agent 9 adopts aluminum dihydrogen phosphate, phosphoric acid or PA80 glue.

[0036] The method for preparing the refractory material for the grate cooler comprises the following steps:

[0037] The raw materials of high-purity mullite, clay, cermet, fused mullite, and white corundum are crushed, ground, and sieved to obtain high-purity mullite, clay, cermet, fused mullite, and white corundum powder. Mixing the above powders to obtain the primary mix;

[0038] Add large-grained andalusite, sma...

Embodiment 2

[0041] In an embodiment of the present invention, a refractory material for a grate cooler, the refractory material for a grate cooler includes the following raw materials in parts by weight: 85 parts of high-purity mullite, 55 parts of clay, 18 parts of large particle andalusite, small particle 7 parts of andalusite, 15 parts of cermet, 7 parts of fused mullite, 13 parts of white corundum, 5 parts of α-alumina, 2.5 parts of magnesium silicate, 7 parts of binder.

[0042] The binding agent 9 adopts aluminum dihydrogen phosphate, phosphoric acid or PA80 glue.

[0043] The method for preparing the refractory material for the grate cooler comprises the following steps:

[0044] The raw materials of high-purity mullite, clay, cermet, fused mullite, and white corundum are crushed, ground, and sieved to obtain high-purity mullite, clay, cermet, fused mullite, and white corundum powder. The above powders are mixed to obtain the primary mix;

[0045] Add large-grained andalusite, sm...

Embodiment 3

[0048] In an embodiment of the present invention, a refractory material for a grate cooler, the refractory material for a grate cooler includes the following raw materials in parts by weight: 90 parts of high-purity mullite, 50 parts of clay, 16 parts of large particle andalusite, small particle 8 parts of andalusite, 14 parts of cermet, 8 parts of fused mullite, 14 parts of white corundum, 6 parts of α-alumina, 3 parts of magnesium silicate, and 8 parts of binder.

[0049] The binding agent 9 adopts aluminum dihydrogen phosphate, phosphoric acid or PA80 glue.

[0050]The method for preparing the refractory material for the grate cooler comprises the following steps:

[0051] The raw materials of high-purity mullite, clay, cermet, fused mullite, and white corundum are crushed, ground, and sieved to obtain high-purity mullite, clay, cermet, fused mullite, and white corundum powder. The above powders are mixed to obtain the primary mix;

[0052] Add large-grained andalusite, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com