Metal glazed tile and preparation method thereof

A technology of glazed tiles and metallic glazes, applied in the field of ceramic tiles, can solve the problems of inability to realize filigree inlaid with gold and copper, three-dimensionality, poor layering, etc., and achieve obvious layering, strong three-dimensionality, and easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

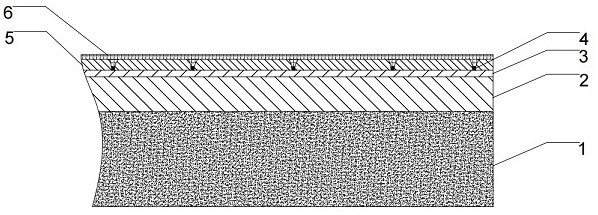

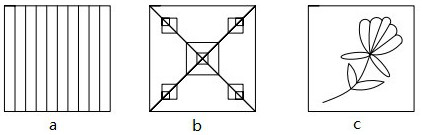

[0058] A metal glazed tile ( image 3 It is the front view of the metal glazed tile), including the base body 1, the bottom glaze layer 2, the pattern layer 3, the texture layer 4, the surface glaze layer 5, and the metal glaze layer 6 arranged in sequence from bottom to top.

[0059] The glaze material of the bottom glaze layer comprises 3 parts of ball clay, 99 parts of glaze powder, 0.4 part of sodium tripolyphosphate and 0.25 part of sodium carboxymethyl cellulose in parts by weight. The glaze-forming powder includes, in parts by weight: 48 parts of silicon dioxide, 23 parts of aluminum oxide, 0.15 part of iron oxide, 0.08 part of titanium dioxide, 9.8 parts of calcium oxide, 3.8 parts of magnesium oxide, 0.15 part of potassium oxide, 0.15 part of sodium oxide 5.20 parts, 0.01 parts of zirconium dioxide, 0.08 parts of barium oxide, 0.45 parts of phosphorus pentoxide, and 0.08 parts of zinc oxide. The glaze material of the bottom glaze layer is uniformly mixed with water a...

Embodiment 2

[0072] A metal glazed tile, comprising a green body 1, an underglaze layer 2, a pattern layer 3, a texture layer 4, a surface glaze layer 5, and a metal glaze layer 6 arranged in sequence from bottom to top.

[0073] The glaze material of the bottom glaze layer includes 2 parts of ball clay, 98 parts of glaze powder, 0.3 part of sodium tripolyphosphate and 0.2 part of sodium carboxymethyl cellulose in parts by weight. The glaze-forming powder includes, in parts by weight: 48 parts of silicon dioxide, 22 parts of aluminum oxide, 0.10 part of iron oxide, 0.05 part of titanium dioxide, 9.5 parts of calcium oxide, 3.5 parts of magnesium oxide, 0.10 part of potassium oxide, 0.10 part of sodium oxide 5.00 parts, 0.05 parts of barium oxide, 0.40 parts of phosphorus pentoxide, and 0.05 parts of zinc oxide. The glaze material of the bottom glaze layer is uniformly mixed with water as a solvent, and its density is 1.75 g / ml.

[0074] The texture layer is prepared by using oily inorgani...

Embodiment 3

[0086] A metal glazed tile, comprising a green body 1, an underglaze layer 2, a pattern layer 3, a texture layer 4, a surface glaze layer 5, and a metal glaze layer 6 arranged in sequence from bottom to top.

[0087] The glaze material of the bottom glaze layer comprises 5 parts of ball clay, 100 parts of glaze powder, 0.5 part of sodium tripolyphosphate and 0.3 part of sodium carboxymethyl cellulose in parts by weight. The glaze-forming powder includes, in parts by weight: 49 parts of silicon dioxide, 23 parts of aluminum oxide, 0.20 part of iron oxide, 0.10 part of titanium dioxide, 10.0 parts of calcium oxide, 4.0 parts of magnesium oxide, 0.20 part of potassium oxide, 5.50 parts, 0.01 parts of zirconium dioxide, 0.10 parts of barium oxide, 0.50 parts of phosphorus pentoxide, and 0.10 parts of zinc oxide. The glaze material of the bottom glaze layer is uniformly mixed with water as a solvent, and its density is 1.85 g / ml.

[0088] The texture layer is prepared by using oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com