Two-stage centrifugal compressor for fuel cell

A centrifugal compressor and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of increased compressor power consumption, reduced fuel cell output power, and difficulty in system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

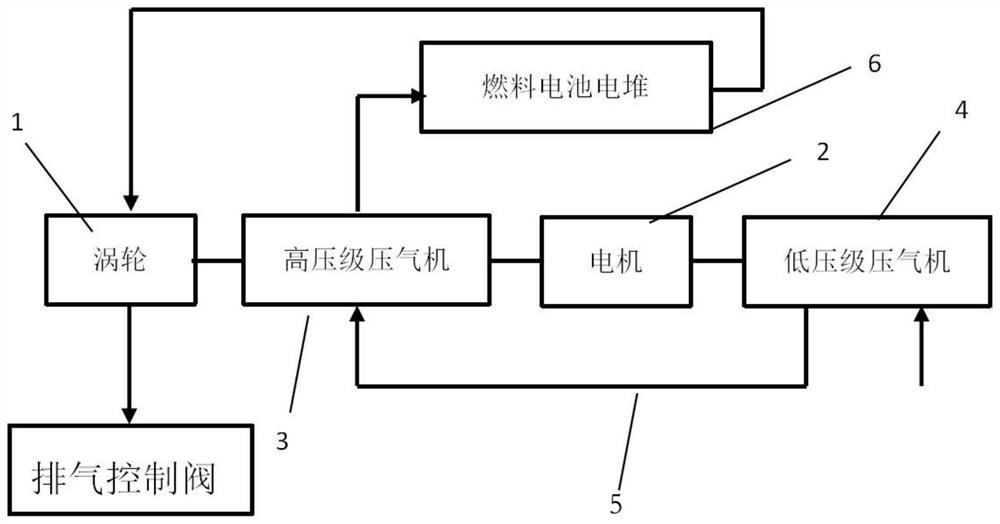

[0028] Such as figure 1 Shown: a two-stage centrifugal compressor for fuel cells, including a turbine 1, a motor 2, a high-pressure compressor 3, a low-pressure compressor 4, connecting pipelines and a fuel cell stack 6, and the turbine 1 is radial turbine.

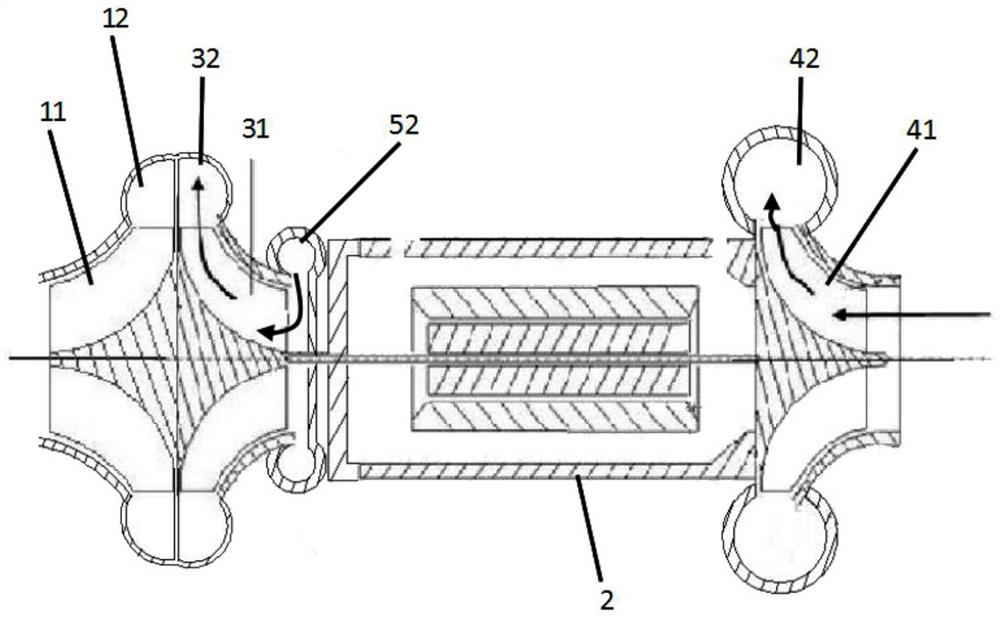

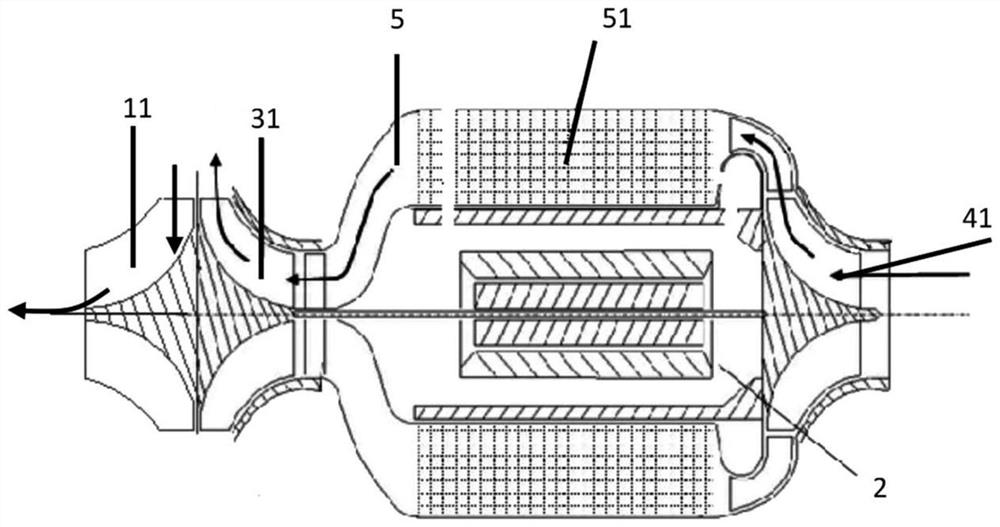

[0029] Such as figure 2 As shown: the high-pressure stage compressor includes a high-pressure impeller 31 and a high-pressure volute 32, and the high-pressure impeller 31 is a radial flow impeller or a mixed flow impeller.

[0030] The low-pressure stage compressor 4 includes a low-pressure impeller 41 and a low-pressure volute 42, the low-pressure impeller 41 is a radial flow impeller or a mixed-flow impeller, and the low-pressure volute is a circumferential annular outlet.

[0031] The motor includes a motor rotor and a stator. The motor shaft is the rotor. The motor shaft is mechanically connected to the high-pressure compressor impeller and the low-pressure compressor impeller. One end of the motor shaft is connect...

Embodiment 2

[0037] Such as figure 1 Shown: a two-stage centrifugal compressor for fuel cells, including a turbine 1, a motor 2, a high-pressure compressor 3, a low-pressure compressor 4, connecting pipelines and a fuel cell stack 6, and the turbine 1 is radial turbine.

[0038] Such as figure 2 As shown: the high-pressure stage compressor includes a high-pressure impeller 31 and a high-pressure volute 32, and the high-pressure impeller 31 is a radial flow impeller or a mixed flow impeller.

[0039] The low-pressure stage compressor 4 includes a low-pressure impeller 41 and a low-pressure volute 42, the low-pressure impeller 41 is a radial flow impeller or a mixed-flow impeller, and the low-pressure volute is a circumferential annular outlet.

[0040] The motor includes a motor rotor and a stator. The motor shaft is the rotor. The motor shaft is mechanically connected to the high-pressure compressor impeller and the low-pressure compressor impeller. One end of the motor shaft is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com