Light-weight and high-strength photoelectric umbilical cable

An umbilical cable, high-strength technology, applied in the direction of power cables including optical transmission components, power cables, insulated cables, etc., can solve the problem that the degree of light weight cannot meet the corresponding requirements, there is no improvement of the outer umbilical cable steel wire spiral reinforcement, Insufficient protection of internal optical cables, etc., to achieve the effect of small bending radius, large longitudinal modulus, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

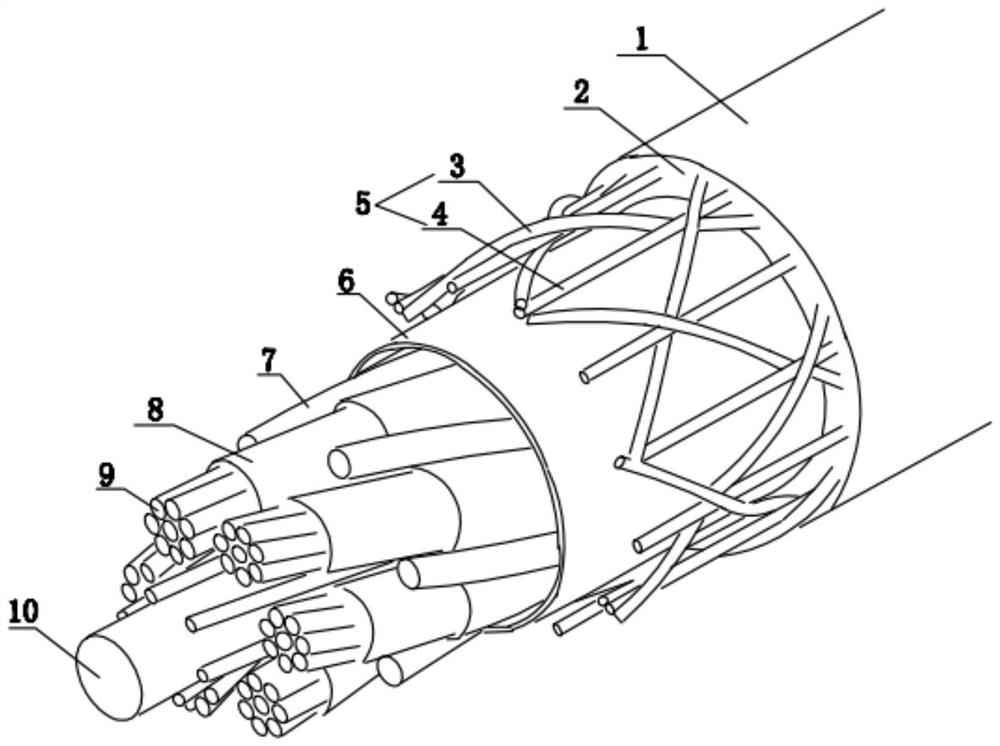

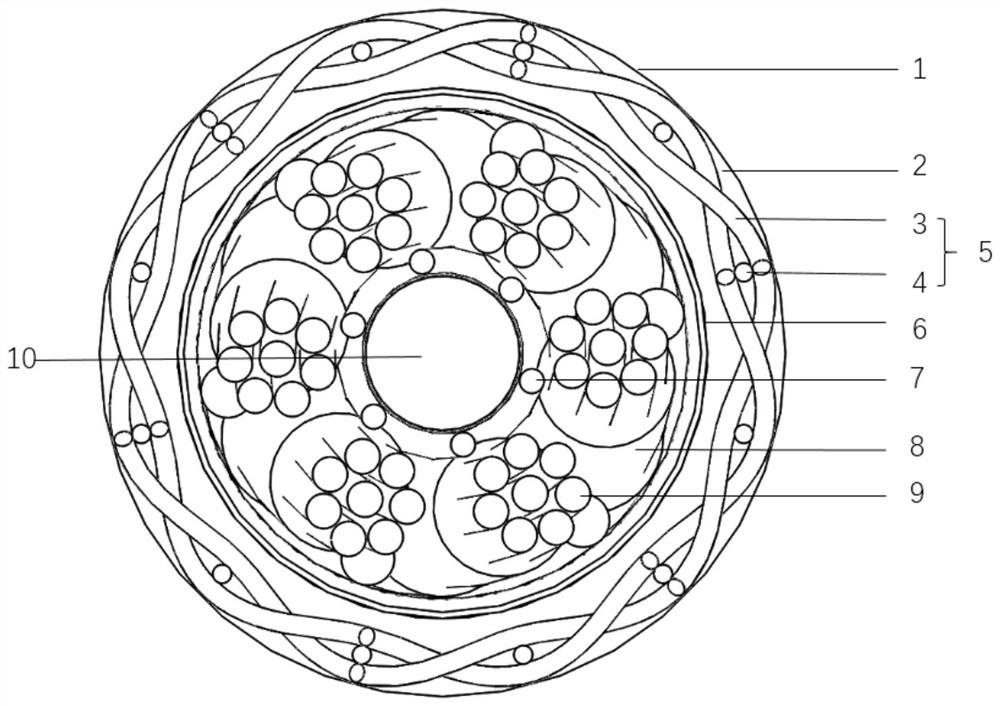

[0027] A light-weight, high-strength photoelectric umbilical cable, including a photoelectric unit, which is determined according to the use of the umbilical cable, such as including optical fiber 7, cable sheath 8, cable 9, pipeline 10, etc. This patent is mainly aimed at innovating the armored structure of the umbilical cable, and proposes a new umbilical cable reinforcement method based on the fiber triaxial braided structure, and provides a feasible solution for the full-depth lightweight umbilical cable. It also includes a flexible sheath 2 for covering the photoelectric unit, and an odd-numbered braided structure reinforcement 5 for enhancing the modulus and strength of the umbilical cable in the longitudinal direction is embedded on the flexible sheath.

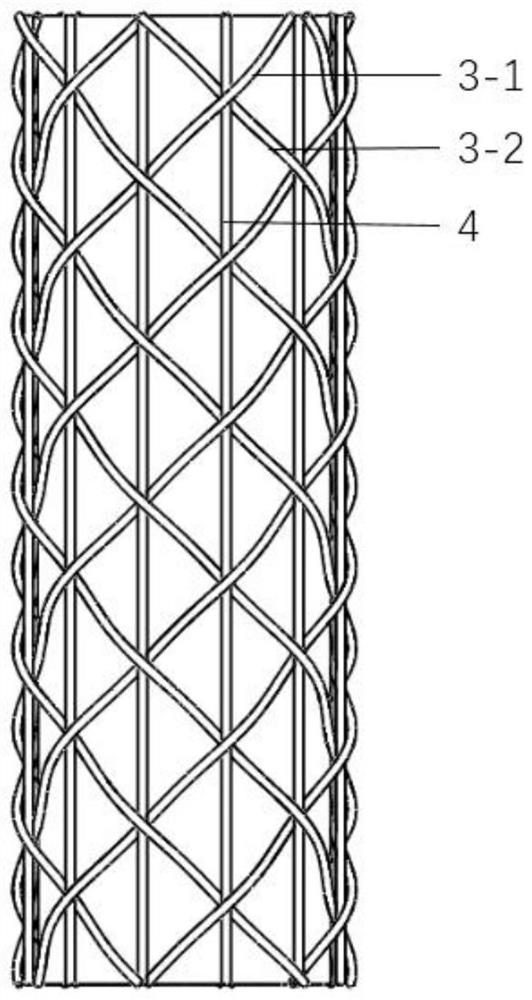

[0028] The odd-numbered braided structure reinforcement 5 is a tubular braided structure formed by braiding strands 3 and a triaxial braided structure formed by longitudinal reinforcing strands 4 located in voids formed...

Embodiment 2

[0038] The same parts of this embodiment and Embodiment 1 will not be described in detail. The difference is that, for the above-mentioned lightweight, high-strength photoelectric umbilical cable, the material of the braided strands is nylon fiber, polyester fiber, aramid fiber, ultra-high One of molecular weight polyethylene fiber, PBO fiber and carbon fiber, the fiber fineness is 2000D.

[0039] The longitudinal reinforcing strand is one of aramid fibers, ultra-high molecular weight polyethylene fibers, PBO fibers, and carbon fibers, and the fiber fineness is 1500D.

[0040] A protective film is provided between the inner side of the flexible sheath and the photoelectric unit. The protective film is a polypropylene film or a polyimide film with a grammage of 10g / m 2 .

Embodiment 3

[0042] The same parts of this embodiment and Embodiment 1 will not be described in detail. The difference is that, for the above-mentioned lightweight, high-strength photoelectric umbilical cable, the material of the braided strands is nylon fiber, polyester fiber, aramid fiber, ultra-high One of molecular weight polyethylene fiber, PBO fiber and carbon fiber, the fiber fineness is 2300D.

[0043] The braiding mode of the braided strands is 96 braids, and the braiding angle is 30°.

[0044] A protective film is provided between the inner side of the flexible sheath and the photoelectric unit, and the protective film is polypropylene film or polyimide film with a weight of 50g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com