Honeycomb-shaped high-porosity and large-aperture lithium battery diaphragm and preparation method thereof

A lithium battery separator, high-porosity technology, applied in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problem of unfavorable electrolyte penetration of ions, reduced battery electrochemical performance, and poor electrolyte affinity. and other problems, to achieve the effect of improving hydrophilicity, facilitating penetration and ion passage, and enhancing liquid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

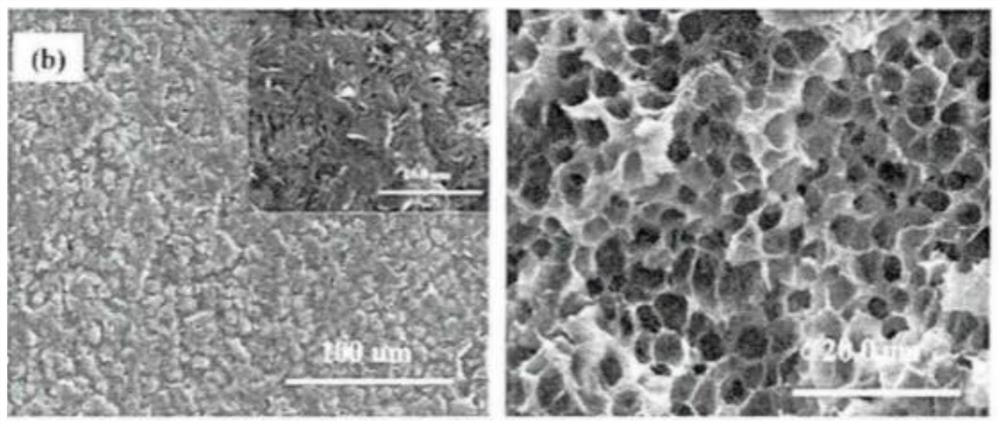

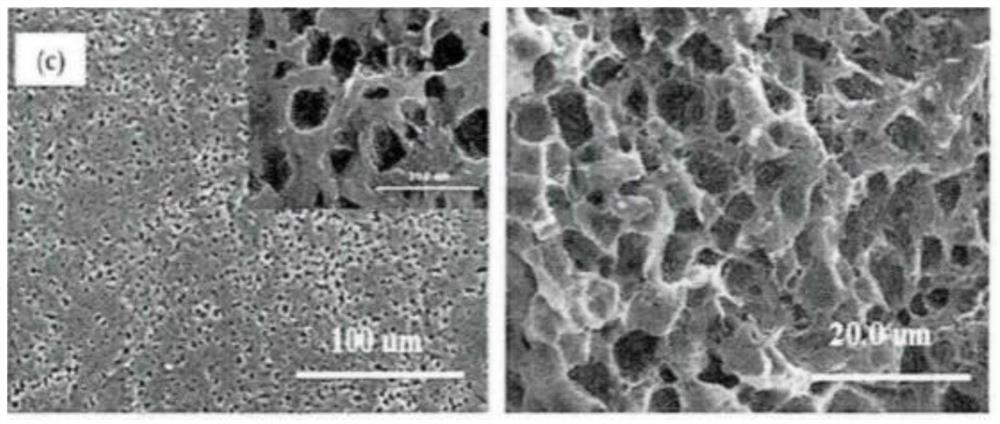

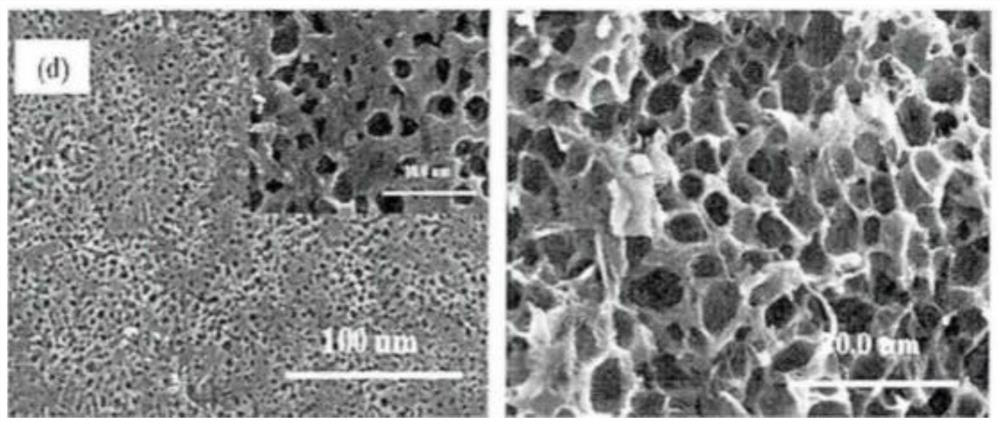

Image

Examples

Embodiment 1

[0028] (1) Mix 30kg of high-density polyethylene, methyl cellulose, and dioctyl phthalate evenly, move to the heating unit of the twin-screw extruder, heat to form a homogeneous phase, the heating temperature is 175°C, and keep warm for 2h, Turn on the gear pump, and the homogeneous material is extruded through the die to form a cast diaphragm.

[0029] (2) Immerse the cast separator in ethanol solution to extract dioctyl phthalate, take out the cast separator after the extraction, and wait until the ethanol is completely volatilized to obtain a honeycomb high-porosity and large-aperture lithium battery separator.

[0030] The distribution ratio of the various components of the raw materials for preparing the lithium battery separator is, in terms of mass fraction, 30 parts of high-density polyethylene, 1 part of methyl cellulose, and 70 parts of dioctyl phthalate.

Embodiment 2

[0032] (1) Mix 30kg of high-density polyethylene, methyl cellulose, and dioctyl phthalate evenly, move to the heating unit of the twin-screw extruder, heat to form a homogeneous phase, the heating temperature is 175°C, and keep warm for 2h, Turn on the gear pump, and the homogeneous material is extruded through the die to form a cast diaphragm.

[0033] (2) Immerse the cast separator in ethanol solution to extract dioctyl phthalate, take out the cast separator after the extraction, and wait until the ethanol is completely volatilized to obtain a honeycomb high-porosity and large-aperture lithium battery separator.

[0034] The distribution ratio of the various components of the raw materials for preparing the lithium battery separator is, in terms of mass fraction, 30 parts of high-density polyethylene, 2 parts of methyl cellulose, and 70 parts of dioctyl phthalate.

Embodiment 3

[0036] (1) Mix 30kg of high-density polyethylene, methyl cellulose, and dioctyl phthalate evenly, move to the heating unit of the twin-screw extruder, heat to form a homogeneous phase, the heating temperature is 175°C, and keep warm for 2h, Turn on the gear pump, and the homogeneous material is extruded through the die to form a cast diaphragm.

[0037] (2) Immerse the cast separator in ethanol solution to extract dioctyl phthalate, take out the cast separator after the extraction, and wait until the ethanol is completely volatilized to obtain a honeycomb high-porosity and large-aperture lithium battery separator.

[0038] The distribution ratio of each component of the raw materials for preparing the lithium battery separator is, in terms of mass fraction, 30 parts of high-density polyethylene, 5 parts of methyl cellulose, and 70 parts of dioctyl phthalate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com