Novel aluminum-based water-absorbing MOFs material with high stability as well as preparation method and air water collection application thereof

A high-stability, new type of technology, applied in chemical instruments and methods, water supply devices, drinking water devices, etc., can solve the problems of material water absorption reduction, environmental hazards, poor stability, etc., to achieve uniform shape, strong frame structure, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

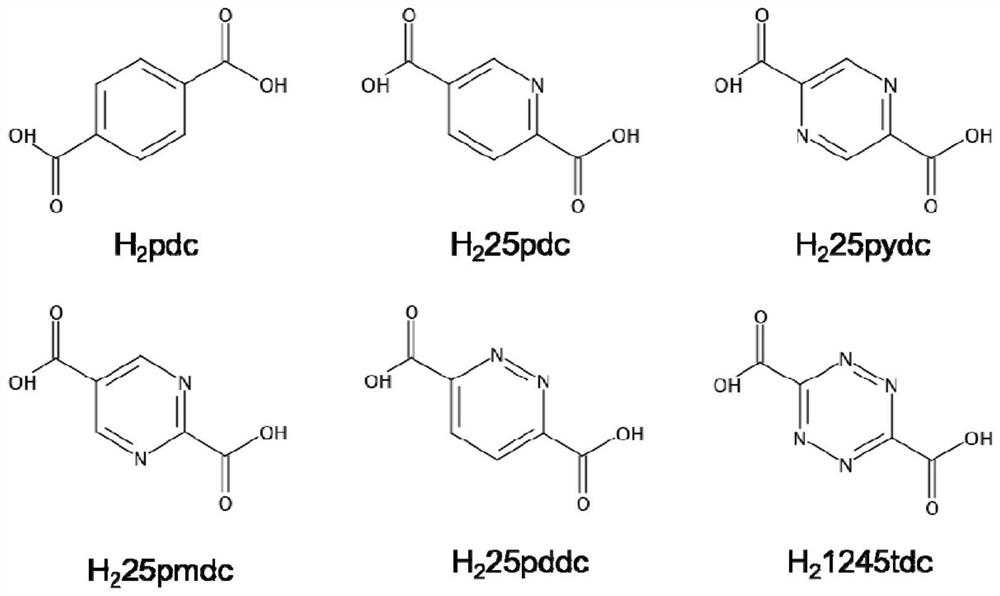

Method used

Image

Examples

Embodiment 1

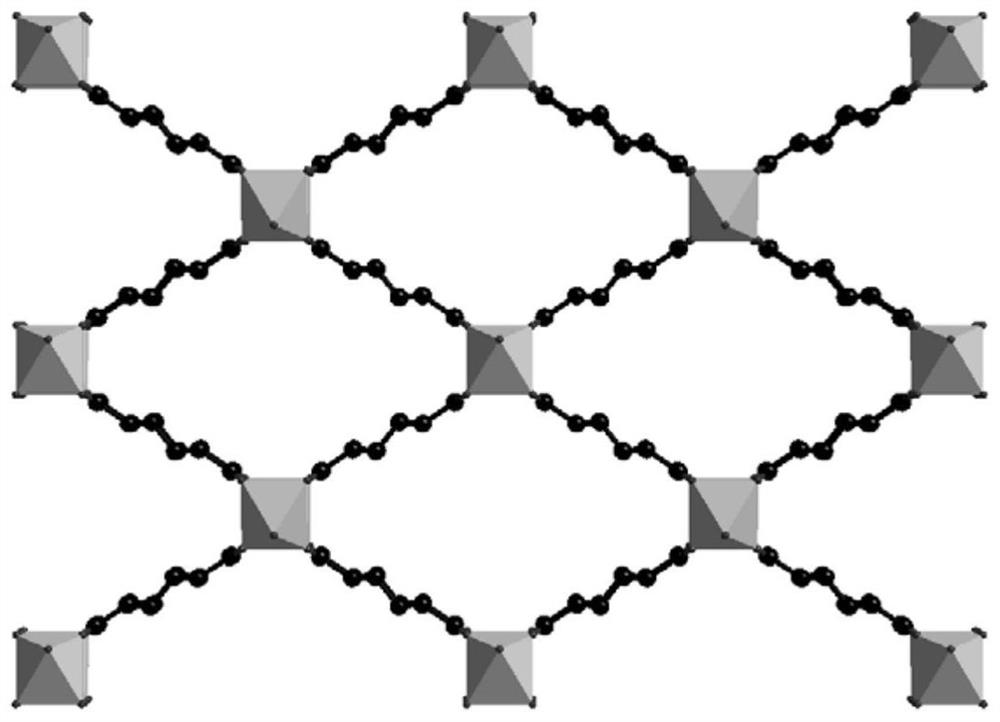

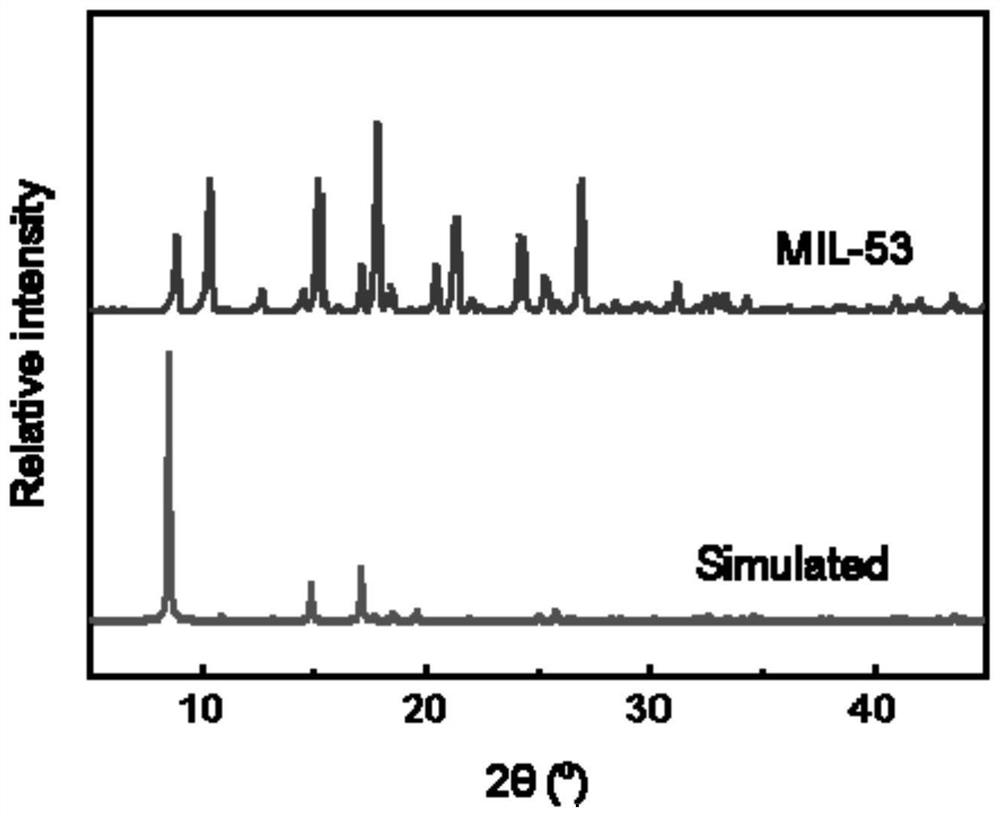

[0048] 1mmol H 2 pdc and 1 mmol AlCl 3 ·6H 2 O was dissolved in 5 mL of deionized water and sonicated for 15 minutes to obtain a cloudy solution. Subsequently, the reaction kettle was placed in an oven at 220° C. for three days. The solid obtained by the reaction was washed with methanol and dried in the air to obtain the flexible metal-organic framework material MIL-53. The microscopic crystal structure schematic diagram of the material is shown in figure 2 , PXRD characterization spectrum data see image 3 , SEM pictures see Figure 4 . Then vacuum-dried at 423K for 12 hours to obtain a flexible metal-organic framework material.

[0049] In order to characterize the water adsorption performance of MIL-53, an isothermal water adsorption test was carried out on MIL-53. Take a 20mg MIL-53 sample, set the test temperature to 25°C, and test the isothermal water adsorption curve at room temperature. The isotherm water adsorption curve is shown in Figure 5 . From the ad...

Embodiment 2

[0051] 1mmol H 2 25pydc and 2mmol of lithium hydroxide monohydrate were dissolved in 5mL of water, and 5mL of 0.2mol / L aluminum chloride ethanol solution was added dropwise to the solution at 25°C and stirred for 10 minutes. Then the temperature was raised to 100° C., and stirred under reflux for 12 hours. The solid obtained from the reaction was filtered and washed with water and methanol several times to obtain the purified rigid metal-organic framework material ZJU-400. The schematic diagram of the material structure is shown in Figure 7 , PXRD characterization data see Figure 8 , SEM pictures see Figure 9 . Then vacuum-dried at 373K for 12 hours to obtain a rigid metal-organic framework material.

[0052] In order to characterize the pore volume of ZJU-400, a 77K nitrogen isothermal adsorption test was carried out on ZJU-400, and the obtained nitrogen full adsorption curve is shown in Figure 10 , the calculated specific surface area of ZJU-400 is 1270m 2 / g, th...

Embodiment 3

[0060] 1mmol H 2 25pydc and 1mmol sodium hydroxide were dissolved in 5mL of water, and 5mL of 0.4mol / L aluminum nitrate ethanol solution was added dropwise to the solution at 25°C and stirred for 10 minutes. Then the temperature was raised to 80°C, and stirred at reflux for 24 hours. The solid obtained from the reaction was filtered and washed with water and methanol several times to obtain the purified rigid metal-organic framework material ZJU-400, and then vacuum-dried at 353K for 6 hours to obtain a rigid metal-organic framework material. Carry out PXRD test ( Figure 20 ) and room temperature water adsorption test ( Figure 21 ), it can be seen from the test results that the ZJU-400 synthesized in Example 3 and the ZJU-400 synthesized in Example 2 have the same structure and water adsorption properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com