Method for preparing high-purity chloroethylene carbonate through continuous two-stage liquid phase reaction

A technology of chloroethylene carbonate and dichloroethylene carbonate, applied in the field of continuous two-stage liquid phase reaction to prepare high-purity chloroethylene carbonate, can solve the problem of low production efficiency, no separation process, dichlorocarbonic acid Vinyl esters are not easy to separate and other problems, to achieve the effect of improving product quality, strong selectivity, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

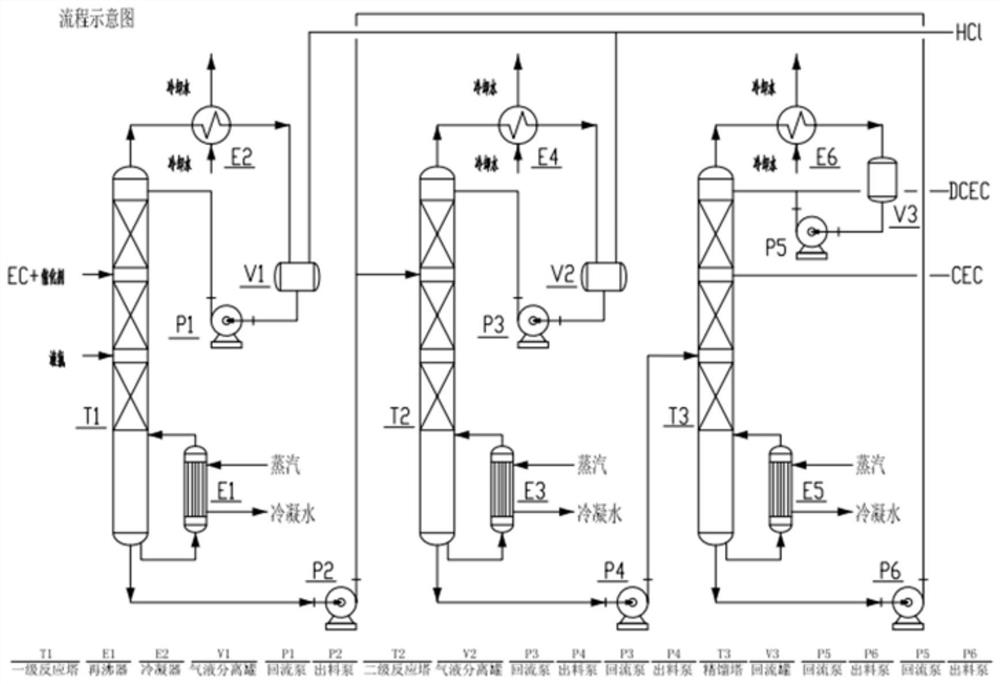

Image

Examples

Embodiment 1

[0036]Step 1): 1000Kg of pre-melted ethylene carbonate (including ethylene carbonate reused in the workshop section) and catalyst azobisisobutyronitrile and liquid chlorine are added to the primary chlorination reaction tower T1, wherein ethylene carbonate: The mass ratio of azobisisobutyronitrile is 10:1, the molar ratio of ethylene carbonate: liquid chlorine is 2:1, the pressure of the primary chlorination reaction tower is controlled at 3.0MPa, and the temperature is 90°C. The gas phase of the light components at the top of the tower (hydrogen chloride and a small amount of entrained ethylene carbonate, etc.) is discharged from the top of the tower, condensed by the condenser E2, and then enters the reflux tank V1, and the non-condensable gas hydrogen chloride is discharged from the top of V1, and the condensate (containing ethylene carbonate) The residence time of ethylene carbonate, catalyzer, liquid chlorine etc. added in the primary chlorination reaction tower by reflux ...

Embodiment 2

[0040] The ethylene carbonate charging capacity of embodiment 2 is identical with embodiment 1, and difference is only, each parameter is different, and in embodiment 2, in step 1), ethylene carbonate: the mass ratio of azobisisobutyronitrile is 8 : 1, ethylene carbonate: the molar ratio of liquid chlorine is 3:1, the pressure of the primary chlorination reaction tower is 2.0MPa, and the temperature is 100°C. The residence time of each component in the primary chlorination reaction tower T1 is 2 hours;

[0041] The pressure of the secondary chlorination reaction tower in step 2) is 2.0 MPa, and the temperature is 110°C. The residence time of each component in the primary chlorination reaction tower T1 is 2 hours;

[0042] In step 3), the pressure of the rectifying tower is 300 Pa, and the temperature is 70°C. The qualified product chloroethylene carbonate was 1334.00Kg, the yield was 95.89%, and the purity was 99.91%.

Embodiment 3

[0044] Embodiment 3 is identical with the ethylene carbonate charging amount of embodiment 1, and difference only is that each parameter is different, and in embodiment 3, in step 1), ethylene carbonate: the mass ratio of azobisisobutyronitrile is 12 : 1, the molar ratio of ethylene carbonate: liquid chlorine is 3:1, the pressure of the primary chlorination reaction tower is 3.5MPa, and the temperature is 70°C. The residence time of each component in the primary chlorination reaction tower T1 is 2 hours;

[0045] The pressure of the secondary chlorination reaction tower in step 2) is 3.5MPa, and the temperature is 80°C. The residence time of each component in the primary chlorination reaction tower T1 is 2 hours;

[0046] In step 3), the pressure of the rectifying tower is 600 Pa, and the temperature is 100°C. The qualified product chloroethylene carbonate was 1343.61Kg, the yield was 96.65%, and the purity was 99.92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com