High-temperature-resistant low-compression-set chloroprene rubber composition and preparation method and special preparation equipment thereof

A chloroprene rubber and permanent deformation technology, applied in the field of rubber production technology, can solve the problems of poor compression performance and high temperature resistance of auto parts, and achieve the effects of long service life, excellent high temperature compression deformation resistance, and safe and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

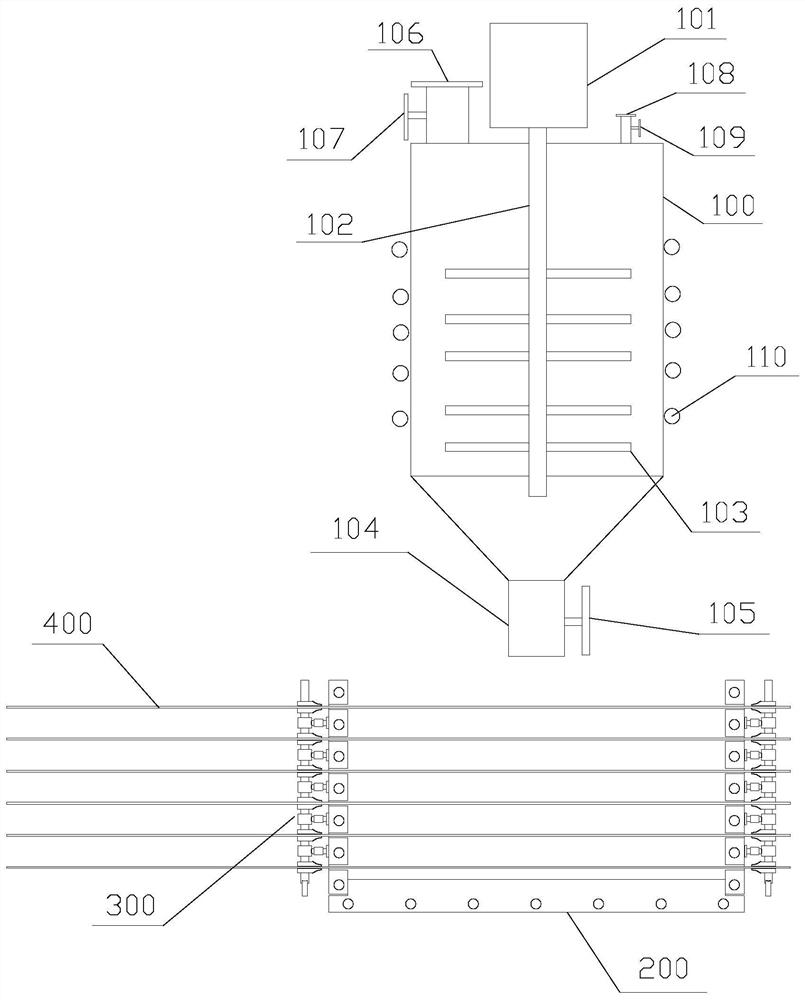

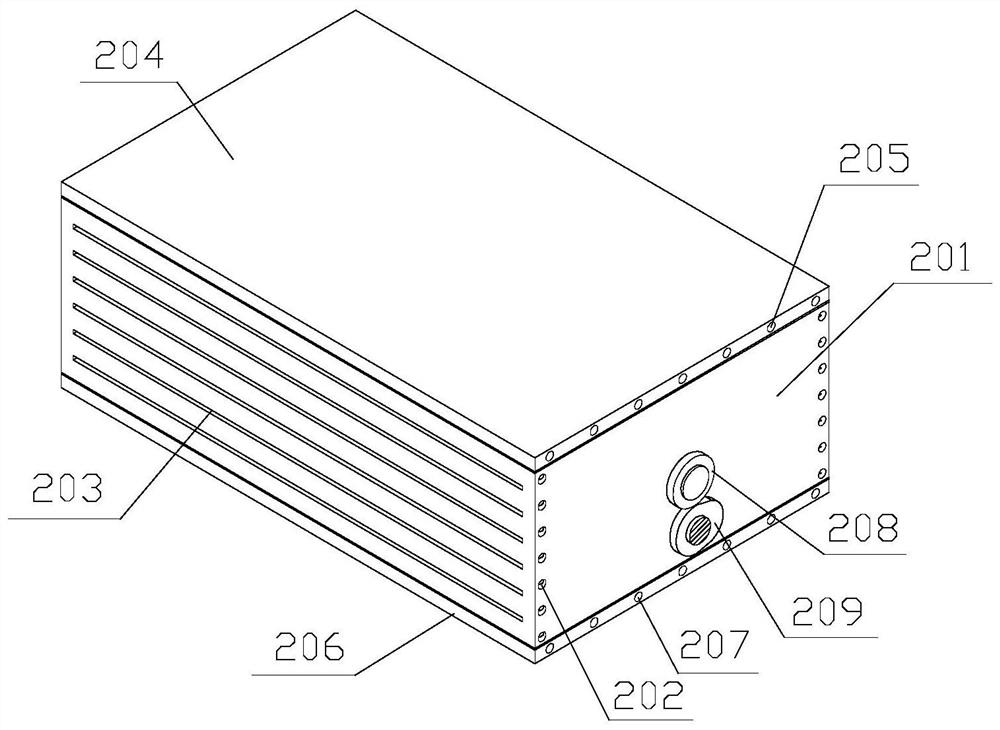

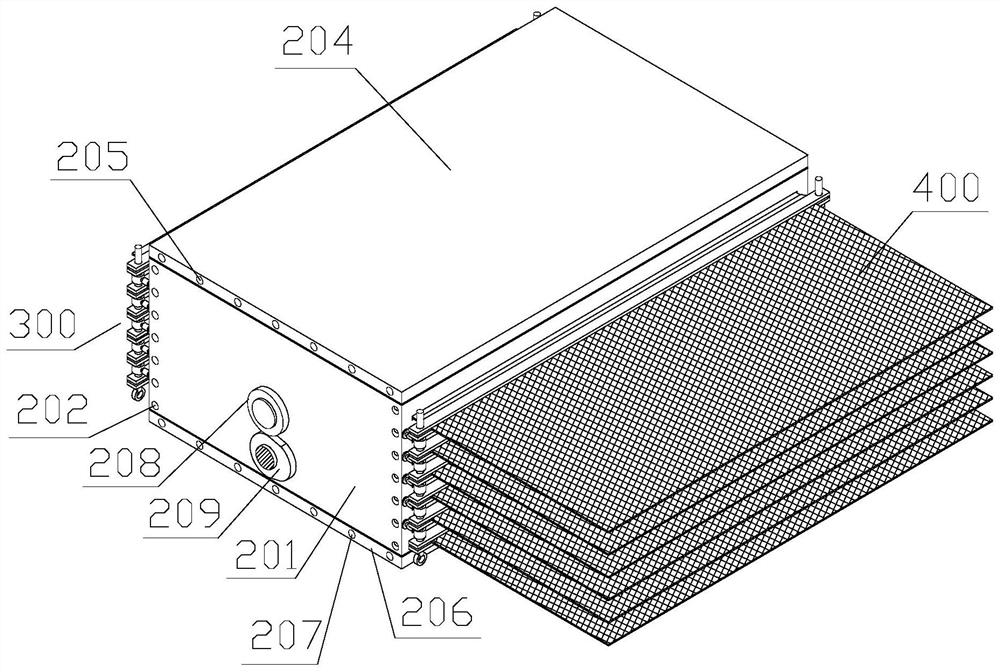

[0039] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

[0040]The invention discloses a chloroprene rubber composition resistant to high temperature and low compression permanent deformation. The weight fraction of each component in the formula is as follows: 92-113 parts of neoprene rubber, 10-50 parts of fast-extrusion furnace black, thermal cracking carbon black 20-80 parts, lamp smoke carbon black 10-60 parts, plasticizer 10-30 parts, high-activity zinc oxide 2-7 parts, high-activity magnesium oxide 3-8 parts, anti-aging agent 5-10 parts, stearin 1-4 parts of acid, 0.5-2 parts of accelerator, 0.5-2 parts of vulcanizing agent. The working principle and advantages of the present invention are: the chloroprene rubber of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com