High-voltage transformation ratio LLC resonant converter based on low-turn high-voltage transformation ratio planar transformer and integrated magnetic part

A planar transformer, high-voltage technology, applied in the direction of transformer/inductor coil/winding/connection, high-efficiency power electronic conversion, transformer/inductance parts, etc., can solve the problem of complex winding structure, large number of turns and layers, and efficiency low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

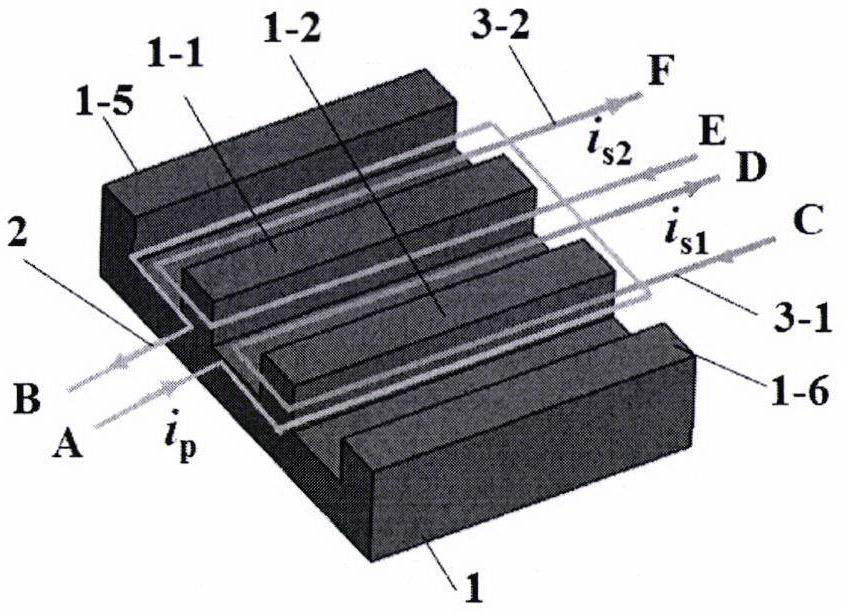

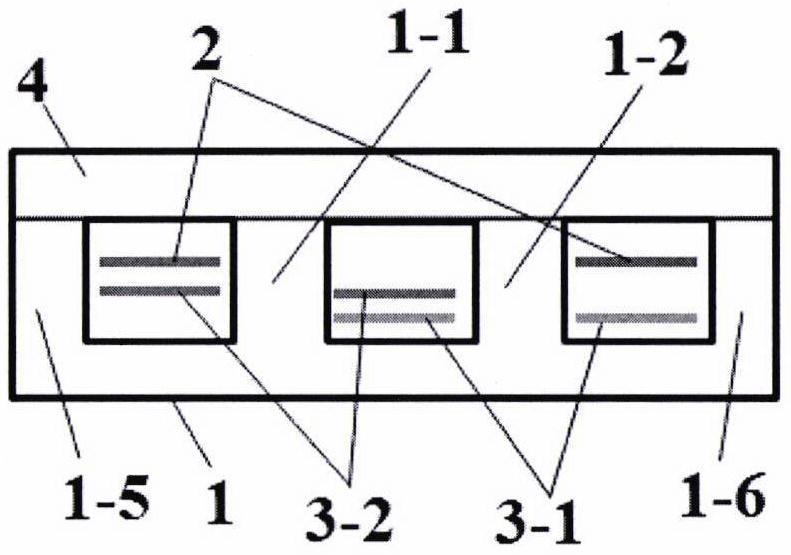

[0029] Refer to attached figure 1 , 2 , a planar transformer with low turns and high voltage ratio, including two iron cores and three windings; one of the iron cores is divided into two by the middle column of the traditional planar "E" type iron core, forming the same shape as the traditional planar "E" The side columns 1-5 and 1-6 of the E" type iron core are parallel to the two center columns 1-1 and 1-2, forming a plane shaped iron core 1, and the other iron core is a traditional planar "I" shaped iron core 4; one of the windings is the primary winding 2, all bypassing the plane The two central columns 1-1 and 1-2 of the shaped iron core 1; the other two windings are the secondary windings 3-1 and 3-2, the number of turns is equal, and they are respectively wound on the plane on the two center columns 1-1 and 1-2 of the shaped iron core 1; the plane "I" shaped iron core 4 covers the plane Above the shaped iron core 1, one of the planar transformer structures with l...

Embodiment 2

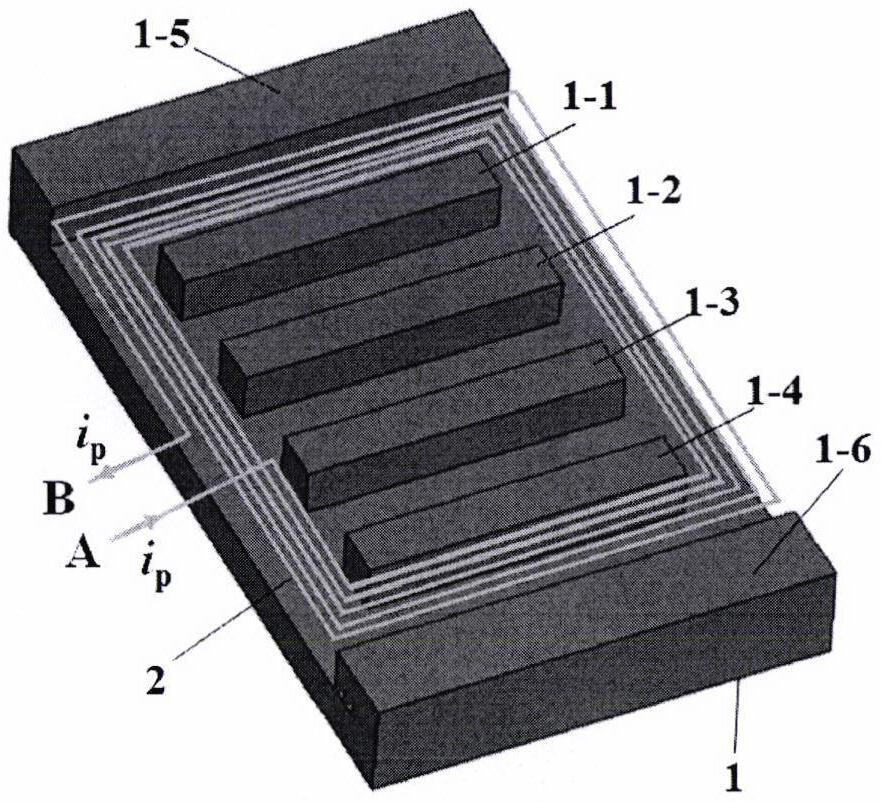

[0031] Refer to attached image 3 , 4 , a planar transformer with low turns and high voltage ratio, divides the central column of the traditional planar "E" core into four, forming four central columns 1-1, 1-2, 1-3 and 1-4 , forming a plane Shaped iron core 1, the four middle columns 1-1, 1-2, 1-3 and 1-4 are shorter than the two side columns 1-5 and 1-6 of the traditional planar "E" type iron core; a The primary winding 2 all bypasses the four iron core columns 1-1, 1-2, 1-3 and 1-4; the four secondary windings 3-1, 3-2, 3-3 and 3- The number of turns of 4 is equal, and is an odd number of turns, respectively wound on the four iron core middle columns 1-1, 1-2, 1-3 and 1-4, respectively from the four secondary side windings 3-1, 3- 2, 3-3 and 3-4 lead to the middle tap C 1 ,E 1 , G 1 、J 1 , the middle tap leads from the bottom of the transformer to the ends C, D, E, F, G, H, J, K of the secondary winding to form a secondary winding structure with odd turns and a midd...

Embodiment 3

[0036] Refer to attached Figure 5 , in the attached image 3 plane in Add a primary side leakage inductance magnetic column 1-7 on the shaped iron core 1, the length direction of the primary side leakage inductance magnetic column 1-7 is the same as that of four middle columns 1-1, 1-2, 1-3, 1-4 The length directions are perpendicular; the primary winding 2 also bypasses the magnetic column 1-7, but the four secondary windings 3-1, 3-2, 3-3, and 3-4 do not bypass the magnetic column 1-7; The number of turns of each secondary winding is an even number of turns, and all of them lead to the middle tap C 1 ,E 1 , G 1 、J 1 , the center tap is located on the same side of the ends C, D, E, F, G, H, J, K of the secondary windings 3-1, 3-2, 3-3, 3-4; forming a low number of turns One of the integrated magnetic parts structure of high voltage ratio planar transformer + primary side leakage inductance; due to the addition of primary side leakage inductance magnetic columns 1-7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com