Hot galvanizing deamination tower wastewater recycling plating assisting tank process

A deammonization tower, hot-dip galvanizing technology, applied in hot-dip plating process, metal material coating process, gaseous effluent wastewater treatment, etc., can solve the problems of sludge impurities, difficult treatment, sewage treatment problems, etc., and achieve saving cost, save the amount of chemicals used, and reduce the effect of sewage treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add the control agent to the tank,

[0022] Zinc chloride content 120g / L,

[0023] Ammonium chloride 170g / L,

[0024] After stirring for 45 minutes, pour it into the fluxing tank, and the temperature of the fluxing agent is 55°C.

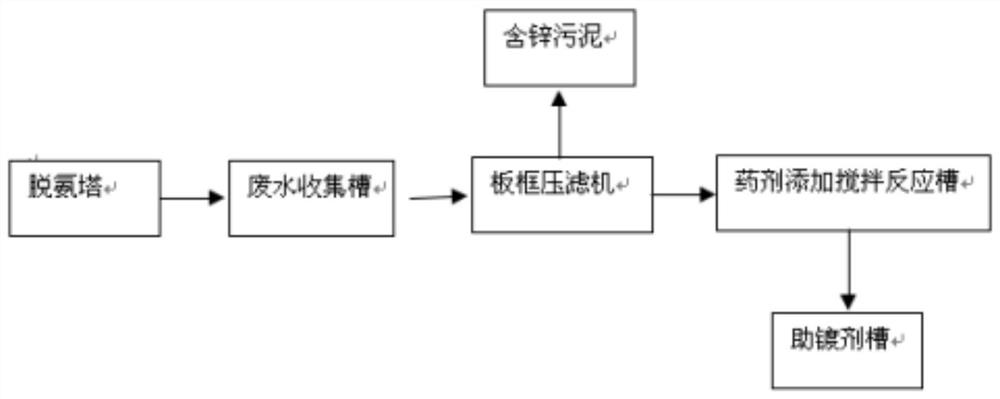

[0025] Such as figure 1 Shown, a kind of hot-dip galvanizing deammonization tower waste water reusing plating aid tank process comprises the following steps:

[0026] Step 1: Discharge the flue gas produced by the hot-dip galvanized zinc pot into the deamination tower for deamination treatment. After the discharge cleaning time is reached, discharge the waste water treated by the deamination tower into the waste water collection tank through the pump;

[0027] Step 2: Filter the wastewater in the wastewater collection tank through a plate-and-frame filter press, remove the sludge and other granular solid impurities in it, obtain a clear and purified liquid, and discharge it into the chemical addition reaction tank;

[0028] Step 3: Detect...

Embodiment 2

[0034] Present embodiment is all the same as embodiment 1 except that content, temperature are different.

[0035] Add the control agent to the tank,

[0036] Zinc chloride content 130g / L,

[0037] Ammonium chloride 180g / L,

[0038] After stirring for 45 minutes, pour it into the fluxing tank, and the temperature of the fluxing agent is 57°C.

Embodiment 3

[0040] Present embodiment is all the same as embodiment 1 except that content, temperature are different.

[0041] Add the control agent to the tank,

[0042] Zinc chloride content 140g / L,

[0043] Ammonium chloride 190g / L,

[0044] After stirring for 45 minutes, pour it into the fluxing tank, and the temperature of the fluxing agent is 60°C.

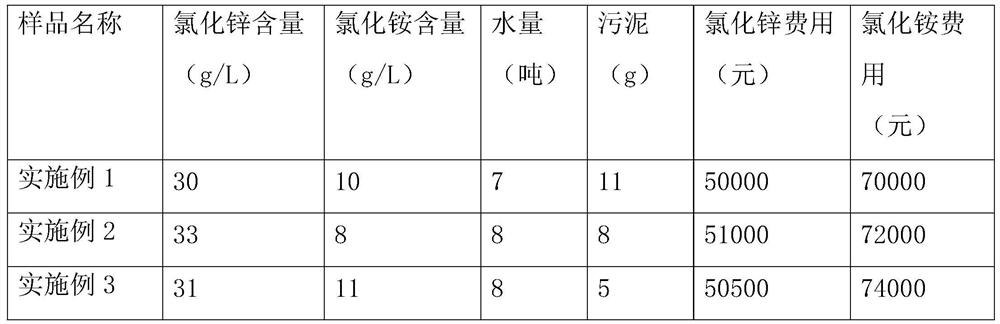

[0045] Embodiment 1-3 waste water content situation table among the present invention in table 1

[0046]

[0047] Compared with the traditional deamination tower wastewater directly discharged to the sewage treatment plant, the present invention is to use the zinc chloride and ammonium chloride in the deammonization tower wastewater to remove the sludge inside the deamination tower wastewater and reuse it in the plating flux tank In addition, the amount of zinc chloride and ammonium chloride solid medicine added in the workshop is reduced, and it also saves a lot of water costs in the workshop. At the same time, it prevents the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com