Adsorbent for deeply removing carbon monoxide in hydrogen, preparation method of adsorbent and method for removing carbon monoxide in hydrogen by adopting adsorbent

A carbon monoxide and adsorbent technology, applied in the field of carbon monoxide adsorbent and its preparation, can solve the problems of high roasting temperature and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation according to the present invention is used for the method for the adsorbent of deep removal of carbon monoxide in hydrogen comprises the steps:

[0056] (1) Dissolving the active component precursor in water and fully stirring to obtain a precursor solution;

[0057] (2) disperse and impregnate an activated carbon carrier with a high specific surface area with the resulting precursor solution;

[0058] (3) drying the impregnated carrier and the precursor solution at a temperature of 40-100° C.; and

[0059] (4) Sintering the dried carrier in an inert atmosphere at a temperature of 150-300° C. for 3-6 hours to obtain the adsorbent.

[0060] Among them, the step (3) is preferably operated in the following manner: first perform rotary evaporation operation on the impregnated carrier and precursor solution; then dry the carrier containing the precursor solution after rotary evaporation at a temperature of 40-100°C.

[0061] In the aforementioned rotary evapora...

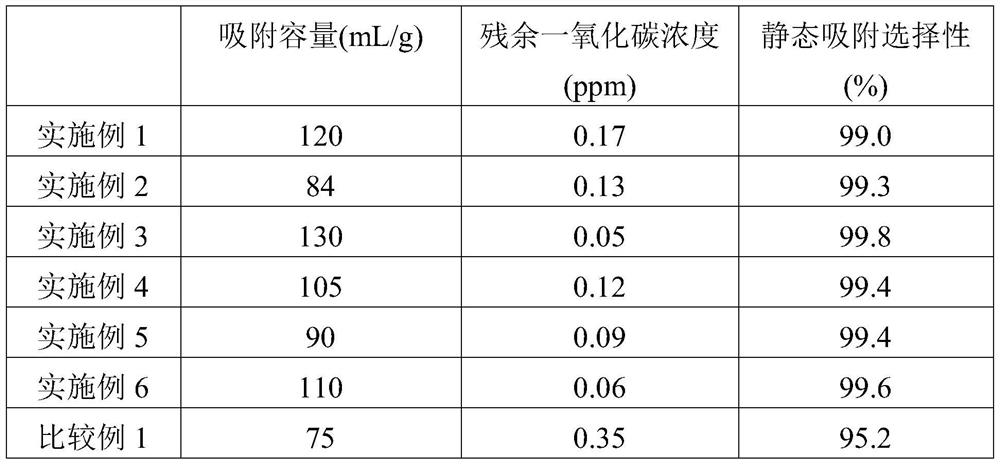

Embodiment 1

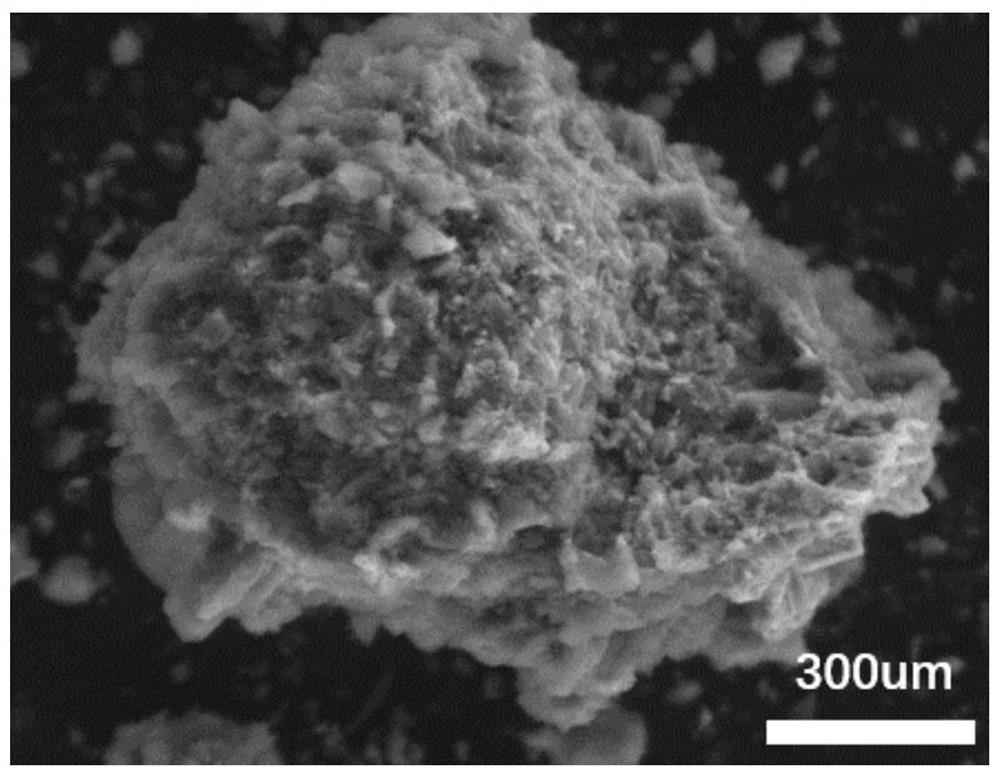

[0077] Dissolve 225g of anhydrous copper nitrate in water, fully stir to dissolve, then disperse and impregnate the solution on 100g of high specific surface area activated carbon carrier, control the temperature of the rotary evaporator flask at 60°C, and rotate and evaporate in a water bath at 20rpm, the ratio of activated carbon to Surface area is 1650m 2 / g, the ratio of metal copper loading to activated carbon is 12.0mmol / g. The impregnated carrier was dried at 80°C as a whole, and then sintered under the protection of an inert gas at 180°C to prepare a carbon monoxide adsorbent.

[0078] The adsorbent was placed in a fixed bed, activated at 300°C for 90 minutes under the protection of inert gas argon, cooled to room temperature, and then high-purity hydrogen containing 1ppm carbon monoxide was introduced, and the gas flow rate was controlled at 400mL / min to test the wear-through of the adsorbent. Permeability curve and adsorption capacity.

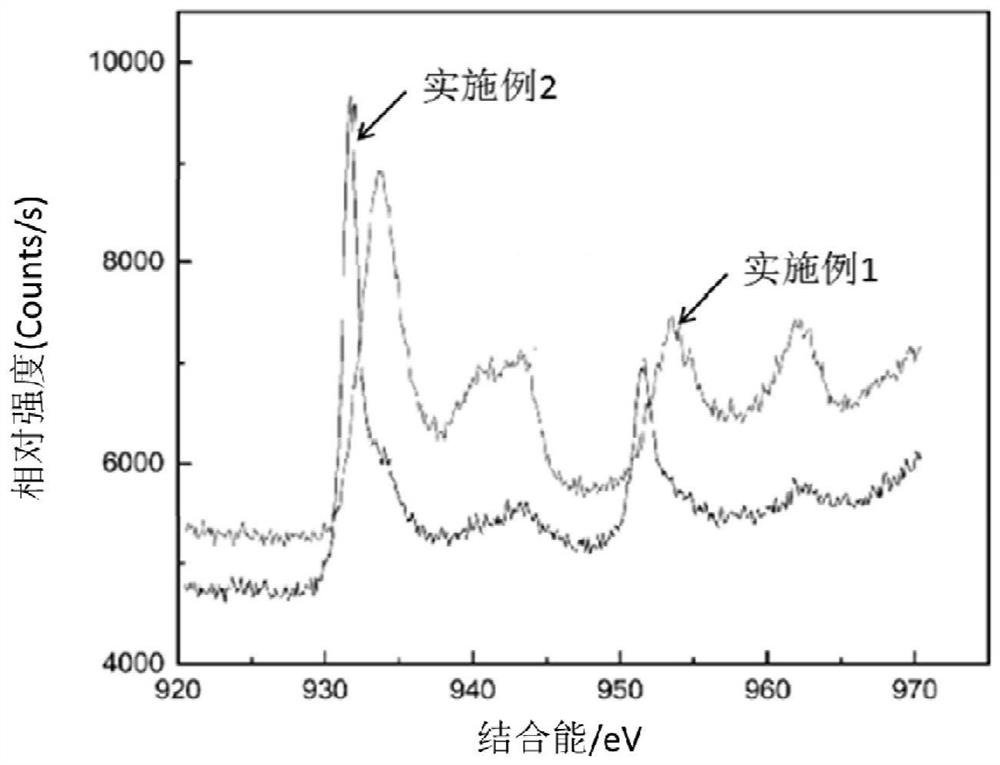

[0079] After characterizati...

Embodiment 2

[0081] Dissolve 225g of anhydrous copper nitrate in water, fully stir to dissolve, and then disperse and impregnate the solution on 100g of high specific surface area activated carbon carrier. Surface area is 1650m 2 / g, the ratio of metal copper loading to activated carbon is 12.0mmol / g. The impregnated carrier was dried at 90°C as a whole, and then sintered under the protection of inert gas at 265°C to prepare the carbon monoxide adsorbent.

[0082] The adsorbent was placed in a fixed bed, activated at 300°C for 90 minutes under the protection of inert gas argon, cooled to room temperature, and then high-purity hydrogen containing 1ppm carbon monoxide was introduced, and the gas flow rate was controlled at 400mL / min to test the wear-through of the adsorbent. Permeability curve and adsorption capacity.

[0083] After characterization of the sintered product by XPS, the active component is copper oxide; the adsorption capacity of the adsorbent for carbon monoxide reaches 84mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com