Multilayer phase-change energy-saving wallboard and preparation method thereof

A wallboard and phase change technology, applied in the field of building wallboard, can solve the problems of complex manufacturing process, insufficient energy saving and environmental protection, etc., and achieve the effect of high density, low cost and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

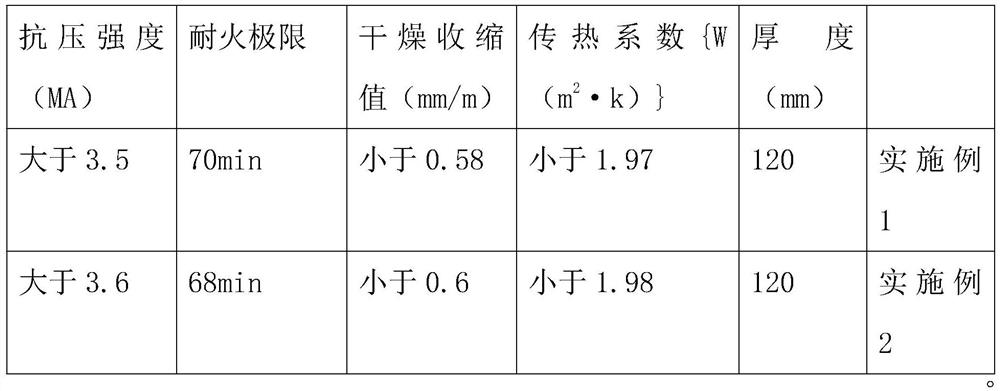

Embodiment 1

[0035] The proportion of chemical mixture is set to 15%, the proportion of phase change material is set to 8%, the proportion of mixed powder is set to 42%, the proportion of additives is set to 10%, and the proportion of organic solvent is set to 25%.

[0036] Silica fume powder, fly ash, zeolite powder, anhydrous gypsum, bentonite, and calcite powder are mixed first, and then the phase change material is made of high-density polyethylene, ethylene-vinyl acetate copolymer, organic kaolinite nano-compound, and paraffin. Raw materials, nanocomposite phase change materials prepared by twin-screw extrusion process, the main screw is 90mm in diameter, the length-to-diameter ratio is 40:1, the secondary screw is 32mm in diameter, and the length-to-diameter ratio is 18:1. After nitriding treatment, a mixture of formamide, propanol, styrene, perchlorethylene, and trichlorethylene is added, and the ratio is 1:0.6:1.2:0.4:0.7, and the stirring equipment is used to fully stir. The speed...

Embodiment 2

[0039] The proportion of chemical mixture is set to 15%, the proportion of phase change material is set to 8%, the proportion of mixed powder is set to 42%, the proportion of additives is set to 10%, and the proportion of organic solvent is set to 25%.

[0040] Silica fume powder, fly ash, zeolite powder, anhydrous gypsum, bentonite, and calcite powder are mixed first, and then the phase change material is made of high-density polyethylene, ethylene-vinyl acetate copolymer, organic kaolinite nano-compound, and paraffin. Raw materials, nanocomposite phase change materials prepared by twin-screw extrusion process, the main screw is 90mm in diameter, the length-to-diameter ratio is 40:1, the secondary screw is 32mm in diameter, and the length-to-diameter ratio is 18:1. After nitriding treatment, a mixture of formamide, propanol, styrene, perchlorethylene, and trichlorethylene is added, and the ratio is 1:0.6:1.2:0.4:0.7, and the stirring equipment is used to fully stir. The rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com